Operation thermal arc 161 s, 10 tig welding parameters for steel, 11 arc welding practice – Tweco 161 S UK User Manual

Page 29

OPERATION

THERMAL ARC 161 S

Manual 0-5183

4-5

4-5

Operation

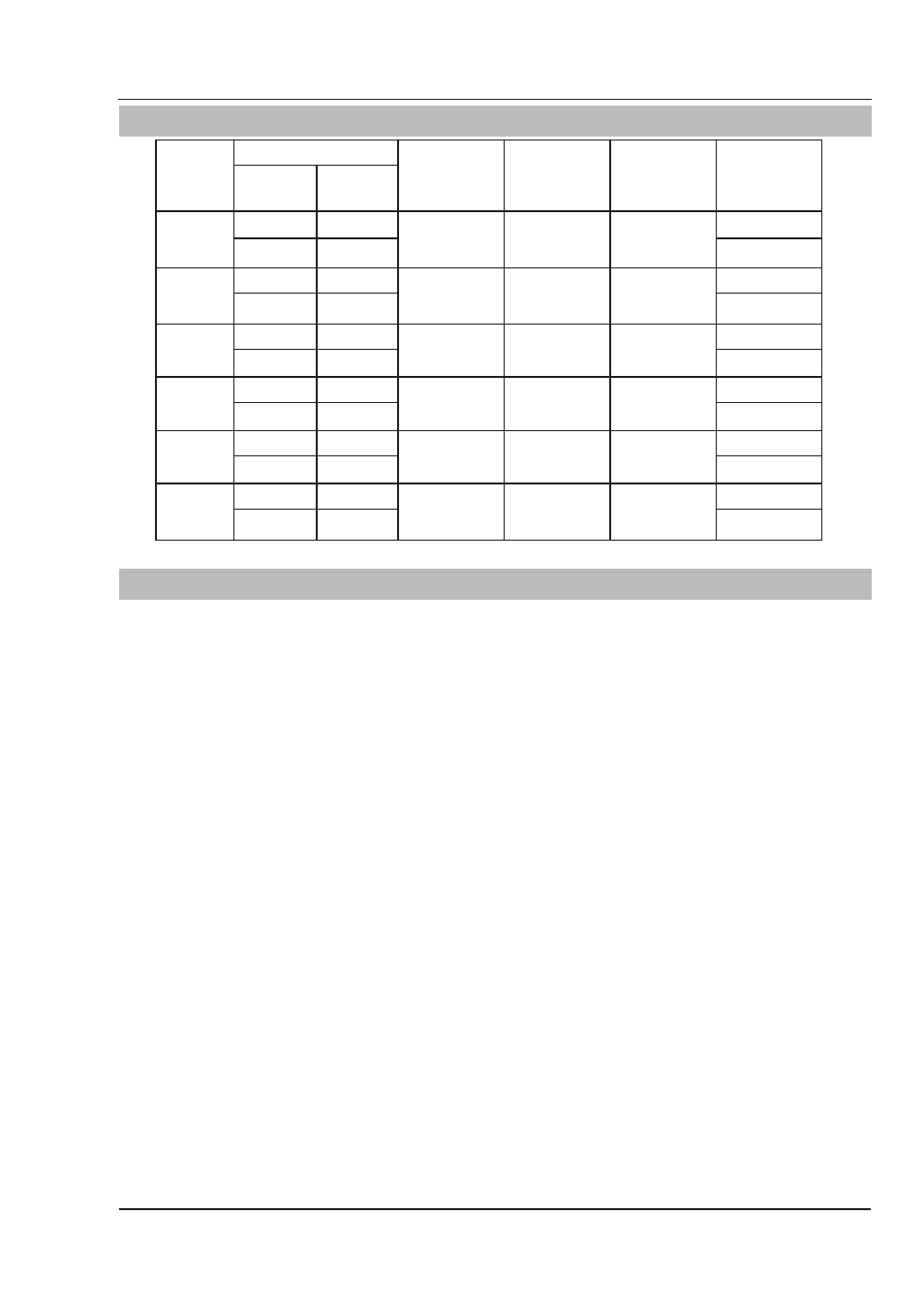

4.10 TIG Welding Parameters for Steel

Base Metal

Thickness

DC Current

Electrode

Diameter

Filler Rod

Diameter

Argon Gas Flow

Rate

Joint / Type

Mild Steel Stainless

Steel

1.0mm

(.040")

35-45

20-30

1.0mm

(.040")

1.6mm

(1/16")

5 LPM

Butt/Corner

40-50

25-35

Lap/Filler

1.2mm

(.045")

45-55

30-45

1.0mm

(.040")

1.6mm

(1/16")

6 LPM

Butt/Corner

50-60

35-50

Lap/Filler

1.6mm

(1/16")

60-70

40-60

1.6mm

(1/16")

1.6mm

(1/16")

7 LPM

Butt/Corner

70-90

50-70

Lap/Filler

3.2mm

(1/8")

80-100

65-85

1.6mm (1/16") 2.4mm ( 3/32")

7 LPM

Butt/Corner

90-115

90-110

Lap/Filler

4.8mm

(3/16")

115-135

100-125

2.4mm (3/32")

3.2mm (1/8")

10 LPM

Butt/Corner

140-165

125-150

Lap/Filler

6.4mm

(1/4")

160-175

135-160

3.2mm (1/8")

4.0mm (5/32")

10 LPM

Butt/Corner

170-200

160-180

Lap/Filler

4.11 Arc Welding Practice

The techniques used for arc welding are almost identical regardless of what types of metals are being joined.

Naturally enough, different types of electrodes would be used for different metals as described in the preceding

section.