Cutmaster a60 – Tweco A60 Cutmaster User Manual

Page 38

CUTMASTER A60

OPERATION

Manual 0-4981

4T-2

1. If attached, remove the ohmic clip then unscrew and

remove the shield cup assembly from the torch head.

Wipe it clean or replace if damaged

2. Remove the Electrode by pulling it straight out of the

Torch Head.

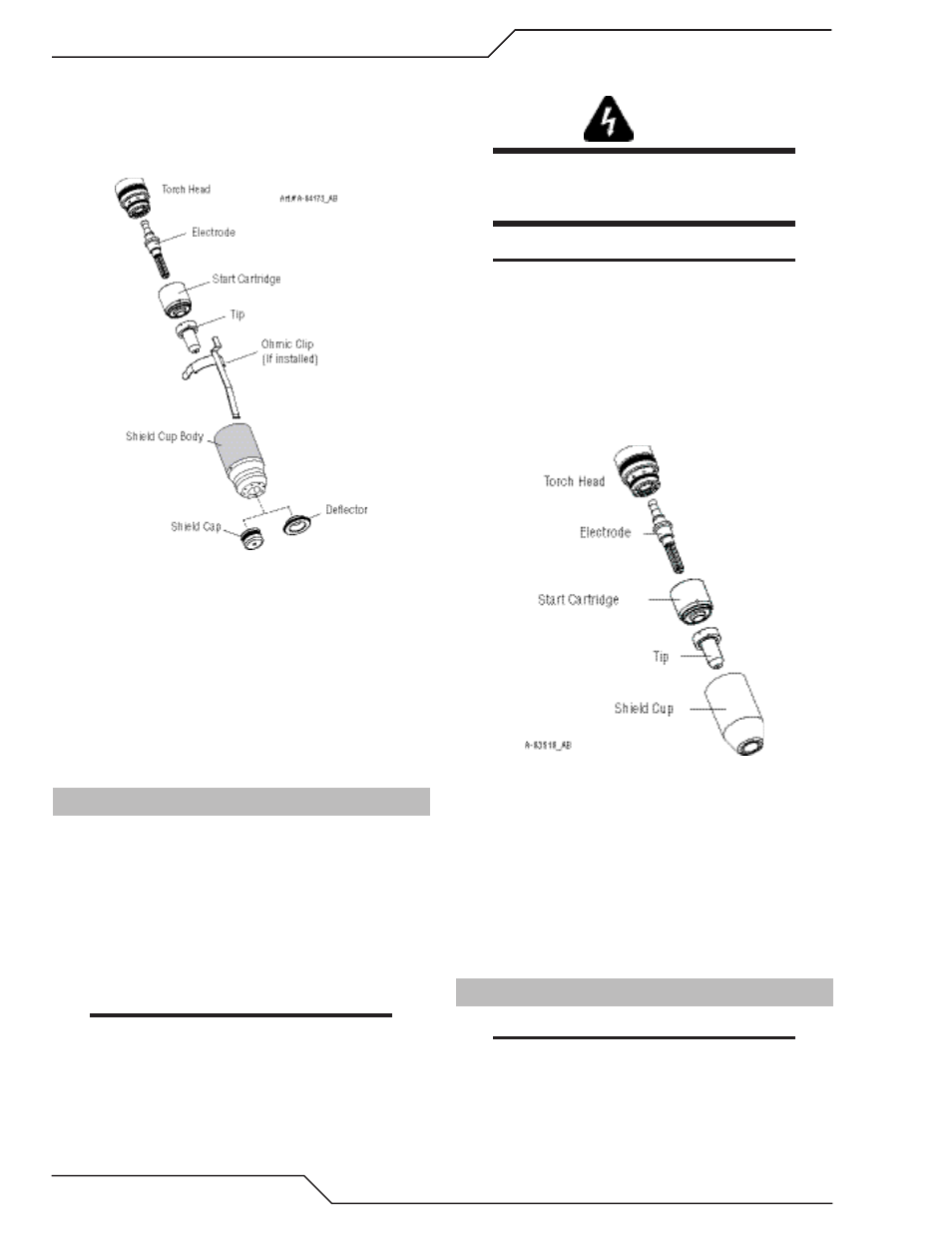

Automation Torch Parts

3. Install the replacement Electrode by pushing it straight

into the torch head until it clicks.

4

. Install the starter cartridge and desired tip for the

operation into the torch head.

5. Hand tighten the shield cup assembly until it is seated

on the torch head. If resistance is felt when installing

the cup, check the threads before proceeding

6. If used, attach the ohmic clip to the shield cup.

4T.03 Machine and Hand Torch Parts Selection

Depending on the type of operation to be done determines the

torch parts to be used.

Type of operation:

Drag cutting, standoff cutting or gouging

Torch parts:

Shield Cup, Cutting Tip, Electrode and Starter Cartridge

NOTE

Torch Parts Selection" and following for additional

information on torch parts.

Change the torch parts for a different operation as follows:

WARNING

Disconnect primary power at the source before

assembling or disassembling torch parts, or torch

and leads assemblies.

NOTE

The shield cup holds the tip and starter cartridge in

place. Position the torch with the shield cup facing

upward to keep these parts from falling out when

the cup is removed.

1. Unscrew and remove the shield cup assembly from

the torch head.

2. Remove the Electrode by pulling it straight out of the

Torch Head.

Torch Parts (Drag Shield Cap & Shield Cup Body Shown)

3. Install the replacement Electrode by pushing it straight

into the torch head until it clicks.

4

. Install the starter cartridge and desired tip for the

operation into the torch head.

5. Hand tighten the shield cup assembly until it is seated

on the torch head. If resistance is felt when installing

the cup, check the threads before proceeding.

4T.04 Cut Quality

NOTE

Cut quality depends heavily on setup and param-

eters such as torch standoff, alignment with the

workpiece, cutting speed, gas pressures, and

operator ability.