05 filling master power supply coolant, 06 input power connections – Tweco Merlin 6000 Master PS User Manual

Page 20

INSTALLATION PROCEDURES

3-2

Manual 0-2568

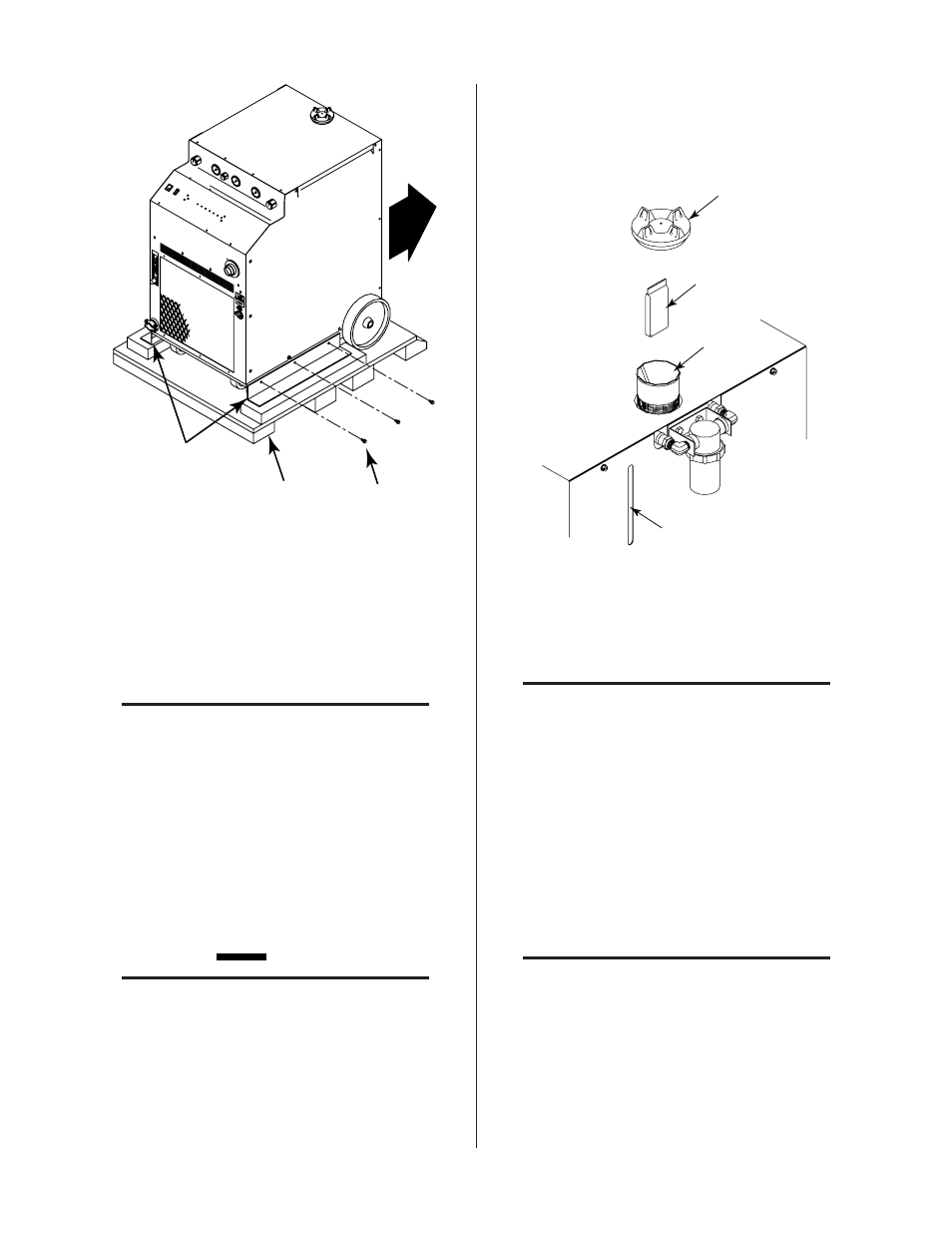

A-01498

Three Bolts

(Each Side)

Shipping Brackets

Shipping Pallet

Figure 3-1 Skid Removal From Power Supply

2. Roll the Power Supply off the skid backwards (rear wheels

first).

3.05 Filling Master Power Supply

Coolant

NOTE

Only the Master Power Supply requires coolant.

DO NOT install coolant in the Slave Power Sup-

ply or the second Master Power Supply if used.

The ambient temperature of the environment where the

Power Supply will be located determines the coolant to

be used. The Standard Torch Coolant supplied with the

system can be used in ambient temperatures down to 10° F

(-12° C).

Optional Super Torch Coolant should be used in areas

where the ambient temperature drops down to -27° F (-33° C).

CAUTION

Use only Thermal Arc Torch Coolant. Use of any

other coolant can result in torch damage, insuffi-

cient thermal protection, and/or pilot arc interfer-

ence.

1. Locate the coolant deionizer bag and remove from

the plastic shipping bag.

2. Remove the coolant filler cap from the reservoir at the

top rear of the Power Supply.

3. Place the deionizer bag into the basket in the coolant

reservoir.

Coolant Reservoir

Filler Cap

Deionizer

Bag

Basket

Coolant Level Indicator

A-00872

Figure 3-2 Coolant Reservoir

4. Carefully pour enough of the supplied Thermal Arc

Torch Coolant into the reservoir to fill it to the FULL

mark on the rear panel.

NOTE

After operating the system more coolant may need

to be added. Allow the pump to operate for ten

minutes to properly purge any air from the coolant

lines before using the system.

5. Reinstall the reservoir coolant filler cap.

3.06 Input Power Connections

The Power Supply accepts input voltages from 200V to

575V, 50 or 60 Hz, three-phase power. Every Power Sup-

ply is factory wired for 460V input. For any other input

voltage, the Power Supply must be reset.

NOTE

Refer to Section 3.07, Voltage Selection.

A. Electrical Connections

The power source must conform to local electric code and

the recommended circuit protection and wiring require-

ments shown in Appendix 1.