Tweco Maximizer 300 Torch for BNFL User Manual

Page 28

OPERATION

4-6

Manual 0-2990

4. With the pilot arc on, the main cutting arc will be

established when the torch is brought within 1/8

- 3/8 in (3 - 10 mm) of the workpiece. If the cut-

ting arc is interrupted and the torch is still acti-

vated, as when cutting expanded metal, the pilot

arc will automatically restart (see NOTE). Deac-

tivating the torch will shut off either the pilot or

main arc, depending on the mode of operation.

NOTES

Pilot arc will automatically restart in AIR, N2 or

Ar/H2 PLASMA Modes, if AUTO-RESTART

function is enabled in the Power Supply.

AUTO-RESTART is always disabled in O

2

Mode.

The AUTO-RESTART is factory set to disable.

Refer to Auto-Restart function in the Power Sup-

ply Operating Manual.

5. Cut with a standoff of 1/8 - 3/8 in (3 - 10 mm)

from the work. The torch should be held perpen-

dicular to the workpiece while cutting. Start cut-

ting slowly and adjust cutting speed for optimum

cutting performance. Refer to Section 4.08, Rec-

ommended Cutting Speeds, for typical cutting

speeds for various materials and material thick-

nesses.

B. Travel Speed

Proper travel speed is indicated by the trail of the arc

which is seen below the plate. The arc can be one of

the following:

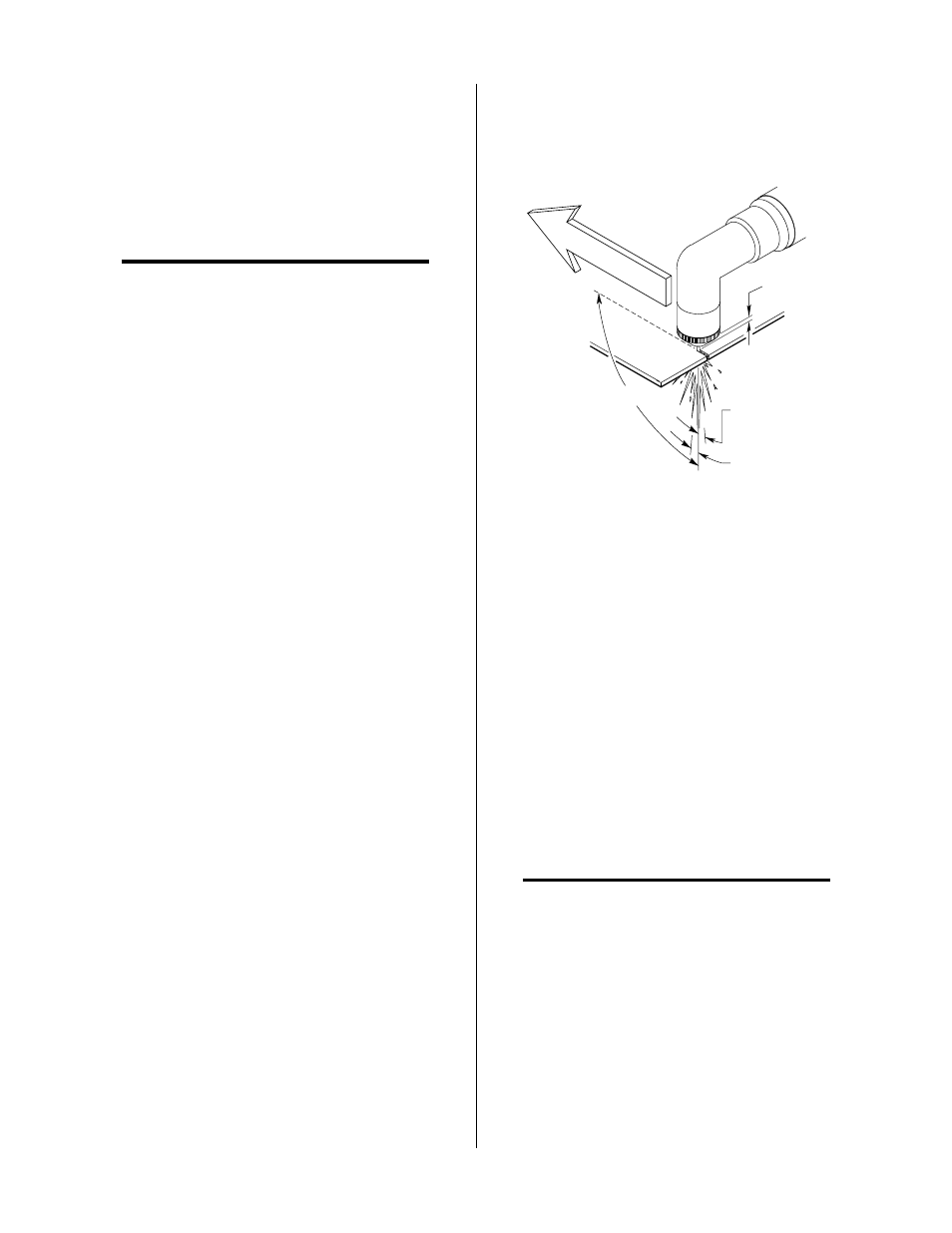

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended for

the best cut using air plasma on stainless or alu-

minum.

2. Leading Arc

The leading arc is directed in the same direction

as torch travel. A five degree leading arc is gener-

ally recommended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direc-

tion as torch travel.

A-01987

Standoff

Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

Figure 4-6 Machine Torch Operation

The arc characteristics vary with gases used, cutting

speed, material, and thickness. Air plasma normally

produces a straight arc (on stainless or aluminum),

while nitrogen plasma generally creates a 5° trailing

arc.

For optimum smooth surface quality, the travel speed

should be adjusted so that only the leading edge of

the arc column produces the cut. If the travel speed

is too slow, a rough cut will be produced as the arc

moves from side to side in search of metal for trans-

fer.

Travel speed also affects the bevel angle of a cut.

When cutting in a circle or around a corner, slowing

down the travel speed will result in a squarer cut.

The power source output should be reduced also.

NOTE

Refer to the Power Supply Operating Manual for

any Corner Slowdown (CSD) adjustments that

may be required.