06 gas selection, 06 gas selection -3 – Tweco Maximizer 300 Torch for BNFL User Manual

Page 21

Manual 0-2990

3-3

INSTALLATION

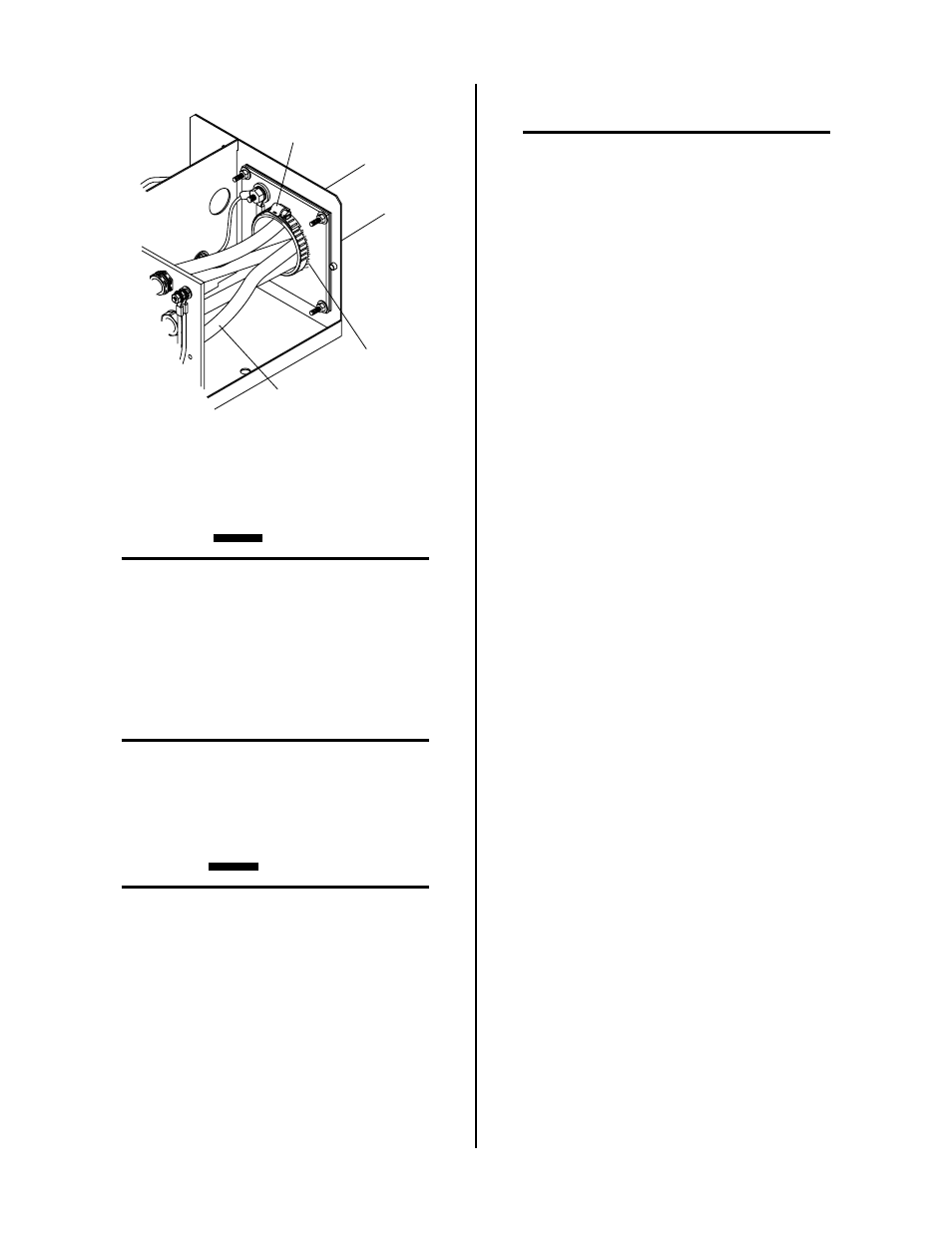

Hose Clamp

Shield Braid

Under Clamp

Torch Leads

A-01443

Figure 3-4 Hose Clamp Installation

9. Check the torch for proper parts assembly.

CAUTION

The torch parts (gas distributor, electrode, tip, and

shield cup) must correspond with plasma and sec-

ondary selection, output current level, and type of

operation (cutting or gouging). Refer to Section

4.04, Torch Parts Selection.

10. Connect the Torch Supply Leads components to

the Arc Starter Box (see NOTE).

NOTE

Refer to the Arc Starter Box Instruction Manual

0-2572 for details on making connections.

3.06 Gas Selection

CAUTIONS

Maximum input gas pressure must not exceed 125

psi (8.6 bar)

Air supply must be free of oil, moisture, and other

contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even com-

plete torch failure. Contaminants may cause poor

cutting performance and rapid electrode wear.

The type of operation will determine the best gases to be

used. Refer to the following and select the plasma and

secondary gases that best fit the operation(s):

A. Plasma Gases

NOTE

Refer to Appendix 2, Cutting Speed Charts, for

proper gas pressure and flow rates.

1. Air Plasma

• Most often used on ferrous or carbon base materi-

als to obtain good quality at faster cutting speeds.

• Air plasma is normally used with air secondary.

• Only clean, dry air is recommended for use as

plasma gas. Any oil or moisture in the air supply

will substantially reduce torch parts life.

• Provides satisfactory results on nonferrous materi-

als.

2. Nitrogen (N2) Plasma

• Provides better cut quality on nonferrous materials

such as stainless steel and aluminum.

• Can be used in place of air plasma with air second-

ary or carbon dioxide (CO

2

).

• Provides much better parts life than air.

• A good clean welding grade nitrogen should be

used.

3. Argon/Hydrogen (Ar/H2) Plasma

• Recommended for use on 3/4 in (19 mm) and thicker

stainless steel. Recommended for 1/2 inch (12 mm)

and thicker nonferrous materials. Ar/H2 is not nor-

mally used for thinner nonferrous materials because

less expensive gases can achieve similar cut qual-

ity.

• Poor cut quality on ferrous materials (carbon steel).

• Provides faster cutting speeds and high cut quality

on thicker materials to offset the higher cost.

• A 65% argon/35% hydrogen mixture should be

used.

4. Oxygen (O

2

) Plasma

• Oxygen is recommended for cutting ferrous mate-

rials (carbon steel).

• Provides faster cutting speeds.

• Provides very smooth finishes and minimizes ni-

tride build-up on cut surface (nitride build-up can

cause difficulties in producing high quality welds

if not removed).