04 torch parts selection, 04 torch parts selection -2 – Tweco Maximizer 300 Torch for BNFL User Manual

Page 24

OPERATION

4-2

Manual 0-2990

4.04 Torch Parts Selection

Depending on the type of operation to be done determines

the torch parts to be used.

Torch parts:

Shield Cup Body, End Cap, Tip, Electrode, Gas Dis-

tributor

Type of operation:

Standoff cutting or gouging

Refer to Section 6.04, Torch Consumables, for the various

torch parts.

CAUTION

Do not interchange parts. Make sure both the tip

and electrode in the torch correspond with the

plasma and secondary in use and the type of op-

eration (cutting or gouging).

To change the torch parts for a different operation use the

following procedure (See Note):

NOTE

A multipurpose wrench is supplied for changing

the tip, electrode and gas distributor in the torch

head.

Multi-Purpose Wrench

(Catalog Number 20-0001)

Used for Electrodes

Used for 11/16" ( 17.5 mm)

Across Tip Flats

Gas Distributor Notch

Used with 11/16" (17.5 mm)Tip

Used for 5/8" (15.9 mm)

Across Tip Flats

Gas Distributor Notch

Used with 5/8" (15.9 mm)Tip

This Side

Towards Torch

A-01639

Figure 4-1 Multi-Purpose Wrench

1. Unscrew and remove the shield cup body and end

cap from the torch head.

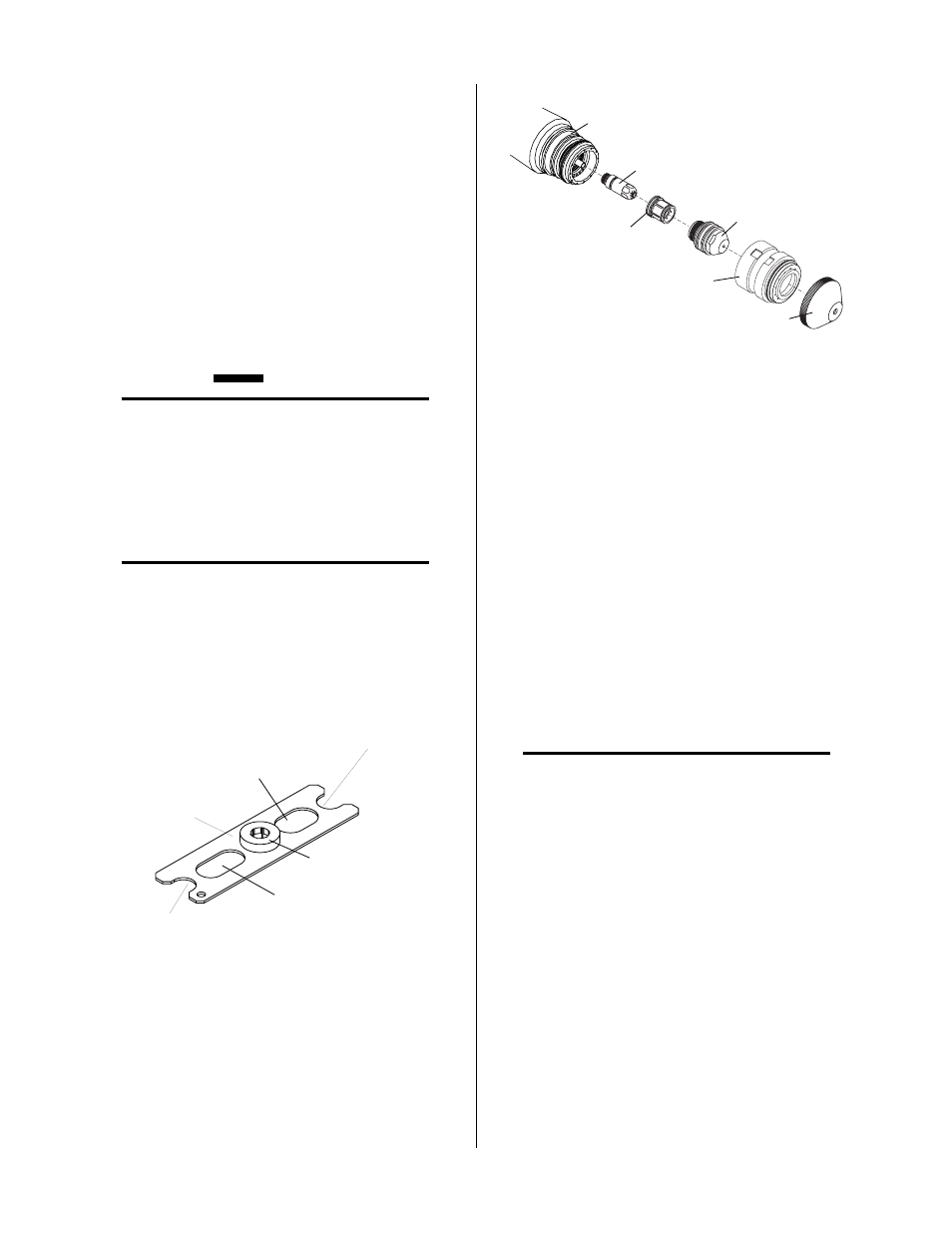

Torch Head

Electrode

Tip

Gas Distributor

Shield Cup Body

Art # A-02207

End Cap

Figure 4-2 Liquid Cooled Torch Parts

2. Using the multipurpose wrench (5/8 inch slot) remove

the tip.

3. Tilt the torch head to remove the gas distributor. The

end of the multipurpose wrench can be used to help

remove the gas distributor.

4. Using the multipurpose wrench (electrode area) re-

move the electrode.

5

. Install the desired electrode for the operation into the

torch head. The circular area around the wrench used

for electrodes will also align the electrode in the torch

head. This will prevent installing electrodes on an

angle and cross threading the electrode in the torch

head.

6. Install the desired gas distributor and tip for the op-

eration into the torch head.

NOTE

Be careful not to overtighten the electrode and tip

when reinstalling.

7. Hand tighten the shield cup body and end cap until it

is seated on the torch head. If resistance is felt when

installing the cup, check the threads before proceed-

ing.