5troubleshooting – Trebor 55E EVOLVE User Manual

Page 25

EVOLVE 55E PUMP OPERATION / MAINTENANCE MANUAL

PAGE 25

5

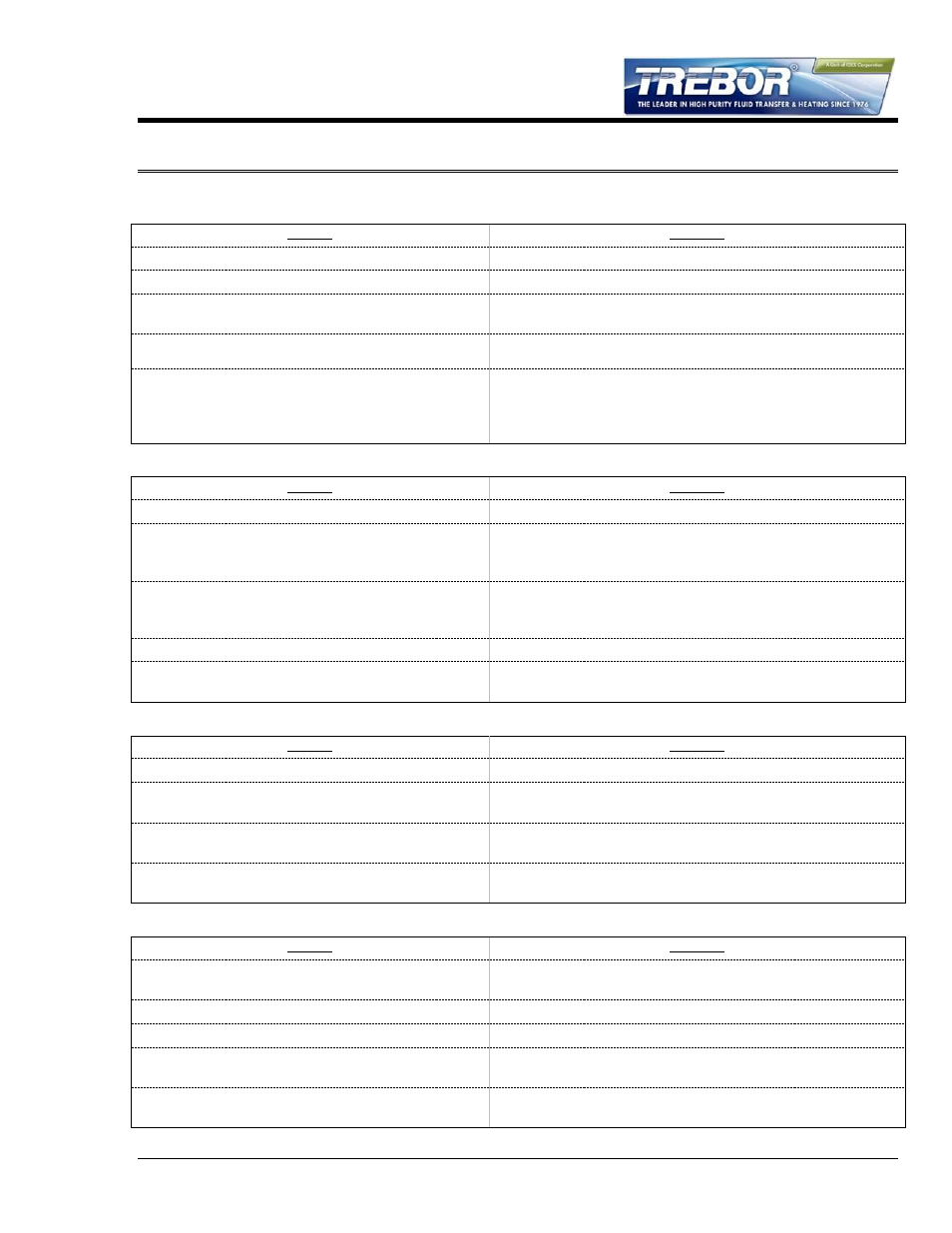

TROUBLESHOOTING

Pump Will Not Start, Fails to Operate

Cause:

Solution:

Insufficient air pressure.

Must be minimum 15 psi at pump air hook-up.

Air lines not attached properly.

Check external controller.

Insufficient air volume (low supply pressure during

running).

See Performance Charts (Figure 3-1) for requirements.

Check for both regulator and control valve capabilities.

Fluid discharge line blocked. Downstream valve

closed, filter plugged or other obstruction.

Remove obstruction.

Probe failure

Check fiber optic probes for correct operation.

Check external controller.

Check for excessive bends in fiber optic cable.

Clean or trim fiber optic cable at the sensor.

Bubbles in Fluid Discharge

Cause:

Solution:

Leaking fluid inlet fitting.

Replace adapter seal.

Leaking main seal.

Tighten union nut to 125 ft-lbs.

Replace diaphragms

Check head and body seal grooves for nicks or scratches.

Pump inlet line pressure reached saturation point

(due to high suction requirement).

Increase diameter of suction supply line (reduces

restriction).

Reduce output flow.

Ruptured (perforated) diaphragm.

Replace diaphragms.

Check bore caps leaking.

Tighten check bore caps

Replace seals.

Fluid Leaks

Cause:

Solution:

Union nut torque low

Tighten union nuts to 125 ft.-lbs.

Leaking main seal.

Replace diaphragms.

Check head and body seal grooves for nicks or scratches.

Check bore cap.

Tighten cap

Remove and replace seal.

Ruptured diaphragm(s)

Replace diaphragms, and any parts that may have been

damaged by fluid exposure.

Erratic Cycling

Cause:

Solution:

Air line or fittings leak in external controller.

Replace tubing or tighten fittings.

Replace controller.

Suction line restricted (cavitation).

Reduce fluid restriction.

Quick exhaust seal not sealing.

Inspect for particles between seal and port. Replace seal.

Check ball(s) not seating.

Inspect check assembly for damage; replace if necessary.

Make sure check balls move freely in sleeves.

Transfer tube leaking.

Tighten transfer tubes and quick grip nuts as described in

Section 4.8.a.