Installation – tekmar 156 Difference Setpoint Control User Manual

Page 5

5 of 12

© 2010 D 156 - 06/10

Using ΔT•hours to Calculate Heat Transfer

Note: BTU = British Thermal Unit, lbm = Pound Mass, USGal = US gallon

To estimate the total amount of heat the system has transferred from the heat source to the storage tank use the equation:

Total Heat Transferred =

Flow

Rate

X

ΔT•hours

X

K

= _____________ BTU

Where:

Flow Rate is that produced by the pump in US Gallons per minute

ΔT•hours is the temperature difference between the source and storage multiplied by the amount of time heat transfer is

taking place (time the pump runs). This variable is calculated for you by the control since the ΔT is not constant.

K is a constant calculated by multiplying the fluid property specific heat (BTU/lbm°F) by density (lbm/USGal) by 60 (min/

hr). For example, water has a specific heat of 1 BTU/lbm°F and a density of 8.33 lbm/USGal. Therefore the value of K

in this case is 1 x 8.33 x 60 = 500.

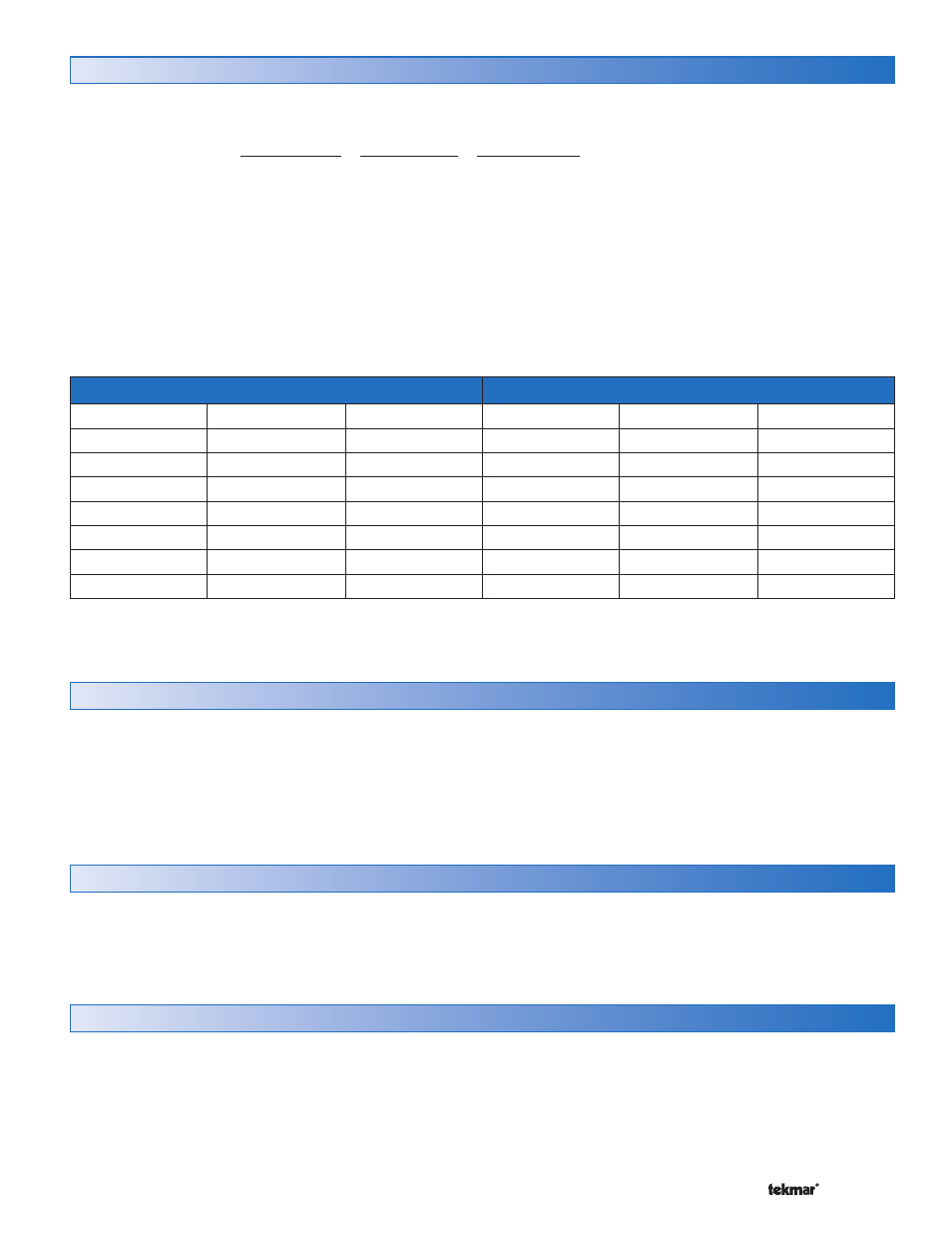

The value of K depends on the percent volume of glycol added to the heat transfer fluid. Select an appropriate K

value from table 1.

•

•

•

Ethylene Glycol Solution

Propylene Glycol Solution

% by Volume

Freezing Point

K @ 120°F (49°C)

% by Weight

Freezing Point

K @ 120°F (49°C)

0

32°F (0°C)

493

0

32 (0°C)

493

10

23°F (-5°C)

482

10

26 (-3°C)

492

20

14°F (-10°C)

472

20

18 (-8°C)

489

30

2°F (-17°C)

460

30

7 (-14°C)

477

40

-13°F (-25°C)

446

40

-8 (-22°C)

466

50

-36°F (-38°C)

429

50

-29 (-34°C)

446

60

-70°F (-57°C)

411

60

-55 (-48°C)

425

Table 1: K values at 120°F (49°C) for different heat transfer solutions based on % glycol. K increases with temperature.

Improper installation and operation of this control could

result in damage to the equipment and possibly even

personal injury. It is your responsibility to ensure that this

control is safely installed according to all applicable codes

and standards. This electronic control is not intended

for use as a primary limit control. Other controls that are

intended and certified as safety limits must be placed into

the control circuit.

Caution

Installation

Step One — Getting Ready

Check the contents of this package. If any of the contents

listed are missing or damaged, please contact your

wholesaler or tekmar sales representative for assistance.

Type 156 includes: One Difference Setpoint Control 156, One

Solar Sensor 085, One Universal Sensor 071, Data Brochures

D 156, D 085, D 070, D 001, Application Brochure A 156.

Note: Carefully read the details of the Sequence of

Operation to ensure that you have chosen the proper

control for your application.

Temperature Monitoring

The 156 will monitor the minimum and maximum Source

and Storage temperatures. These items are available

in the Default menu and may be reset by pressing and

holding the ▲ and ▼ buttons simultaneously for 1 second.

‘Clr’ (clear) will then be displayed followed by the value being

reset to the current sensor temperature. Use this feature to

determine system performance or for troubleshooting.