Installation, Step one, Step two – tekmar 153 Mixing Setpoint Control User Manual

Page 2: Step three, Step four

2

Installation

Caution

Improper installation and operation of this control could result in damage to equipment and possibly even personal

injury. It is your responsibility to ensure that this control is safely installed according to all applicable codes and

standards.

Step One

Getting ready

Check the contents of this package. If any of the contents listed are missing or damaged, please refer to the Limited Warranty

and Product Return Procedure on the back of this brochure and contact your wholesaler or tekmar sales agent for assistance.

Type 153 includes:

• One Control 153 • One Universal Sensor 071

• One Data Brochure D 153 • One Data Brochure D 001

Other information available:

• Essay E 001

Note: Carefully read the Sequence of Operation section in this brochure to ensure that you have chosen the proper control and

understand its functions within the operational requirements of your system.

Step Two

Mounting

The control is mounted in accordance with the instructions in the Data Brochure D 001.

Step Three

Rough-in wiring

All electrical wiring terminates in the two wiring chambers at the bottom front of the control. If the control is to be mounted on

an electrical box, the wiring can be roughed-in at the electrical box prior to installation of the control (see Brochure D 001).

Standard 18 AWG solid wire is recommended for all low voltage wiring to this control.

Caution: Power should not be applied to any of the wires during this rough-in wiring stage.

• Install the Universal Sensor 071 according to the instructions in Data Brochure D 070 and run the wiring back to the control but

don’t connect.

• Install a 24V (ac) Class 2 transformer with a minimum 5 VA rating close to the control, and run the wiring from the transfor-

mer to the control.

A Class 2 transformer must be used. Do not connect any of the transformer terminals to ground.

• Or provide 24 V DC power of at least 0.03 A and run wiring to the control location.

Step Four

Testing and connecting the wiring

Caution

These tests are to be performed using standard testing practices and procedures and should only be carried out by

a properly trained and experienced technician.

A good quality electrical test meter, capable of reading from at least 0 — 200 Volts AC, and at least 0 — 2,000,000 Ohms,

is essential to properly test this control.

At no time should voltages in excess of 28V be measured as power supply to this control.

Test the sensor

This test must be performed

before power is applied to the control and before a sensor is connected to the terminal strip. Test

the sensor(s) according to the instructions printed in the enclosed Data Brochure D 001.

Supply and Boiler Return Sensor Operating Mode

• If a Boiler Return Sensor option is installed, then whenever the measured boiler

return water temperature is near the return minimum, the control starts to close

the 4-way mixing valve in order to divert more hot water back to the boiler. The

Return (2) indicator will be flashing at a slow rate to indicate mixing valve is being

controlled by the Boiler Return (2) sensor reading. When using a Boiler Return

(2) sensor for minimum boiler return protection, it is essential that there always

be water flow past the Boiler Return (2) sensor whenever there is Supply (1)

demand.

Supply Sensor Operating Mode

• If only a Supply Sensor is installed, the control regulates the supply water temperature through applying a floating output signal

to the actuating motor. Supply (1) adjustment sets the setpoint temperature. Adjusting the throttling range will set the temperature

range in which floating output action occurs.

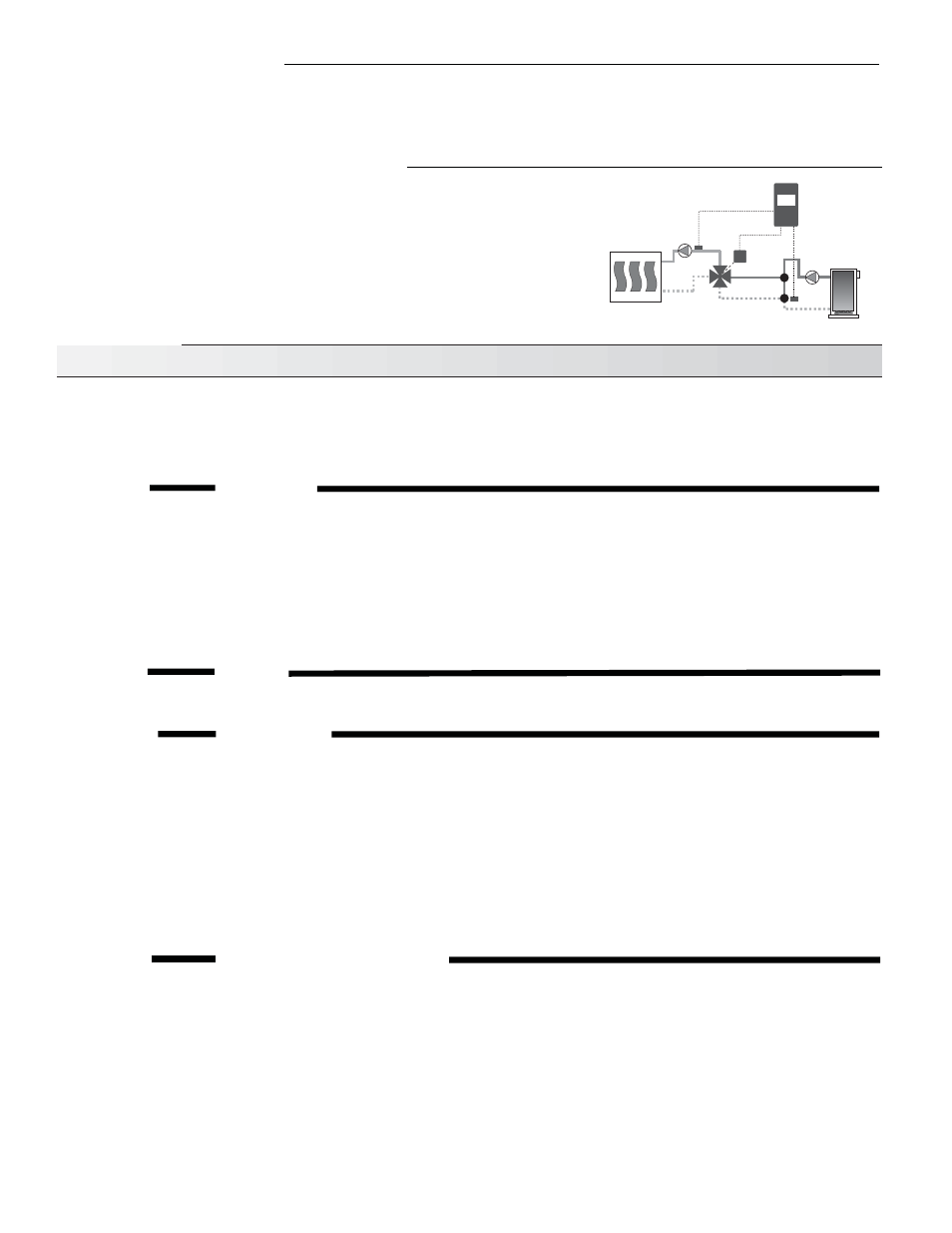

Actuating

Motor

4-Way Valve

Heating System

Boiler Return (2)

Sensor 071

Supply (1)

Sensor 071

M

153

• Install the wiring from the actuating motor to the control.