Bryant Deluxe 4-Way Multipoise Variable-Capacity Direct-Vent Condensing Gas 355MAV User Manual

Page 28

a. Determine location of combustion-air intake pipe con-

nection to combustion-air intake housing as shown in

Fig. 34 for application.

b. Reposition combustion-air intake housing plug fitting in

appropriate unused intake housing connection.

c. Insert perforated disk assembly (factory supplied) in

intake housing where combustion-air intake pipe will be

connected.

d. Install pipe support (factory-supplied in loose parts bag)

into selected furnace casing combustion-air pipe hole.

Pipe support should be positioned to bottom of casing

hole.

e. Insert 2-in. diameter pipe into intake housing.

NOTE:

A 2-in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

f. Install casing hole filler cap (factory-supplied in loose

parts bag) in unused combustion-air pipe casing hole.

g. Drill a 1/8-in. hole in 2-in. combustion-air pipe using

hole in intake housing as a guide.

h. Install a field-supplied No. 6 or No. 8 sheet metal screw

into combustion-air pipe.

NOTE:

DO NOT OVERTIGHTEN SCREW. Breakage of intake

housing or fitting may cause air leakage to occur.

NOTE:

Do not attach combustion-air intake pipe permanently to

combustion-air intake housing since it may be necessary to remove

pipe for service of igniter or flame sensor.

COMBUSTION-AIR INTAKE HOUSING PLUG

FITTING

The combustion-air intake plug fitting must be installed in

unused combustion-air intake housing. This fitting must be

attached by using RTV sealant, or by drilling a 1/8-in. hole

in fitting, using hole in intake housing as a guide. Install a

field-supplied No. 6 or No. 8 sheet metal screw.

NOTE:

DO NOT OVERTIGHTEN SCREW. Breakage of intake

housing or fitting may cause air leakage to occur.

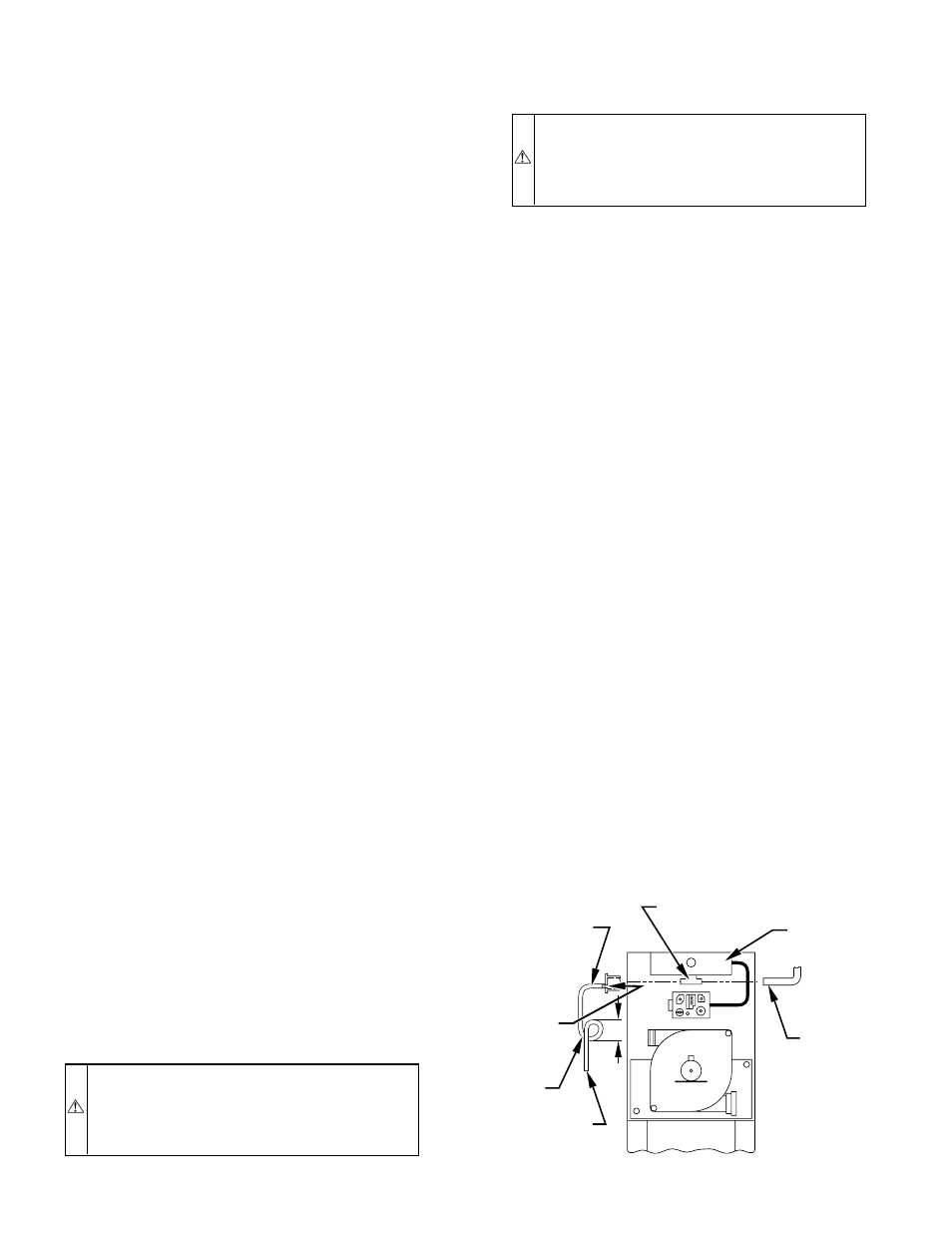

A plugged drain connection has been provided on this

fitting for use when moisture is found in combustion-air

intake pipe and combustion box.

NOTE:

Moisture in combustion-air intake may be result of

improper termination. Ensure combustion-air intake pipe termina-

tion is similar to that shown in Fig. 37, 38, 39, 40, or 41 so it will

not be susceptible to areas where light snow or other sources of

moisture could be pulled in.

If use of this drain connection is desired, drill out fitting’s

tap plug with a 3/16-in. drill and connect a field-supplied

3/8-in. tube. This tube should be routed to open condensate

drain for furnace and A/C (if used), and should be trapped.

(See Fig. 36.)

2. Attach vent pipe as follows:

a. Determine location of vent pipe connection to inducer

housing as shown in Fig. 34 for application.

b. Reposition elastomeric (rubber) inducer housing outlet

cap and clamp to appropriate unused inducer housing

connection. Tighten clamp.

WARNING:

Inducer housing outlet cap must be in-

stalled and fully seated against inducer housing. Clamp

must be tightened to prevent any condensate leakage.

Failure to follow this warning could result in electrical

shock, fire, personal injury, or death.

c. Install pipe support (factory-supplied in loose parts bag)

into selected furnace casing vent pipe hole. Pipe support

should be positioned to bottom of casing hole.

WARNING:

Vent pipe must be installed and fully

seated against inducer housing internal stop. Clamp must

be tightened to prevent any condensate leakage. Failure to

follow this warning could result in electrical shock, fire,

personal injury, or death.

NOTE:

A 2-in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

d. Be certain that mating surfaces of inducer housing

connection, elastomeric coupling, and 2-in. diameter

vent pipe are clean and dry. Assemble the elastomeric

(rubber) vent coupling (with 2 loose clamps) onto

inducer housing connection. Insert the 2-in. diameter

vent pipe through the elastomeric (rubber) coupling and

fully into inducer housing connection until it bottoms on

the internal stop. Tighten both clamps to secure the pipe

to inducer housing. Tighten the clamp screws to 15

in.-lb. of torque.

e. Install casing hole filler cap (factory-supplied in loose

parts bag) in unused combustion-air pipe casing hole.

3. Working from furnace to outside, cut pipe to required

length(s).

4. Deburr inside and outside of pipe.

5. Chamfer outside edge of pipe for better distribution of

primer and cement.

6. Clean and dry all surfaces to be joined.

7. Check dry fit of pipe and mark insertion depth on pipe.

NOTE:

It is recommended that all pipes be cut, prepared, and

preassembled before permanently cementing any joint.

8. After pipes have been cut and preassembled, apply gener-

ous layer of cement primer to pipe fitting socket and end of

pipe to insertion mark. Quickly apply approved cement to

end of pipe and fitting socket (over primer). Apply cement

in a light, uniform coat on inside of socket to prevent

buildup of excess cement. Apply second coat.

9. While cement is still wet, twist pipe into socket with 1/4

turn. Be sure pipe is fully inserted into fitting socket.

10. Wipe excess cement from joint. A continuous bead of

cement will be visible around perimeter of a properly made

joint.

11. Handle pipe joints carefully until cement sets.

Fig. 36—Air Intake Housing Plug Fitting Drain

A93035

COMBUSTION –

AIR PIPE

BURNER

BOX

COMBUSTION – AIR

INTAKE HOUSING

3/8" ID TUBE

TRAP

TO OPEN

DRAIN

3/16"

DRILL

4

″

MIN

—28—