Optional retract installation - bnf/pnp – E-flite Hawker Hurricane 25e PNP User Manual

Page 10

10

E-flite Hurricane 25e PNP/BNF Assembly Manual

EN

Optional Retract Installation - BNF/PNP

Required Parts (included with model)

Wing panel (right and left)

Landing gear door (right and left)

Landing gear mount cover (right and left)

Wheel (2) (removed from fixed gear)

3mm wheel collar with screw (2)

(removed from fixed gear)

3mm x 25mm machine screw (8)

(removed from fixed gear mount)

Transmitter

Receiver battery

Receiver

Required Optional Parts

Retract wire strut (right and left)

Retract cover plate (right and left)

Retract assembly

12-inch (305mm) servo extension (2)

Required Tools and Adhesives

Rotary tool

Cut-off wheel

Vise grip

Phillips screwdriver: #1

Flat file

Hex wrench: 2.5mm

Threadlock

Hobby knife with #11 blade

Drill bit: 3/16-inch (5mm)

Note: We offer a set of pre-bent wire struts

designed specifically for the Hurricane that bolt

directly into the retract units and have all of the

angles preground so it is as simple as installing

the fixed landing gear for those who would

prefer. Please order part number EFL297519.

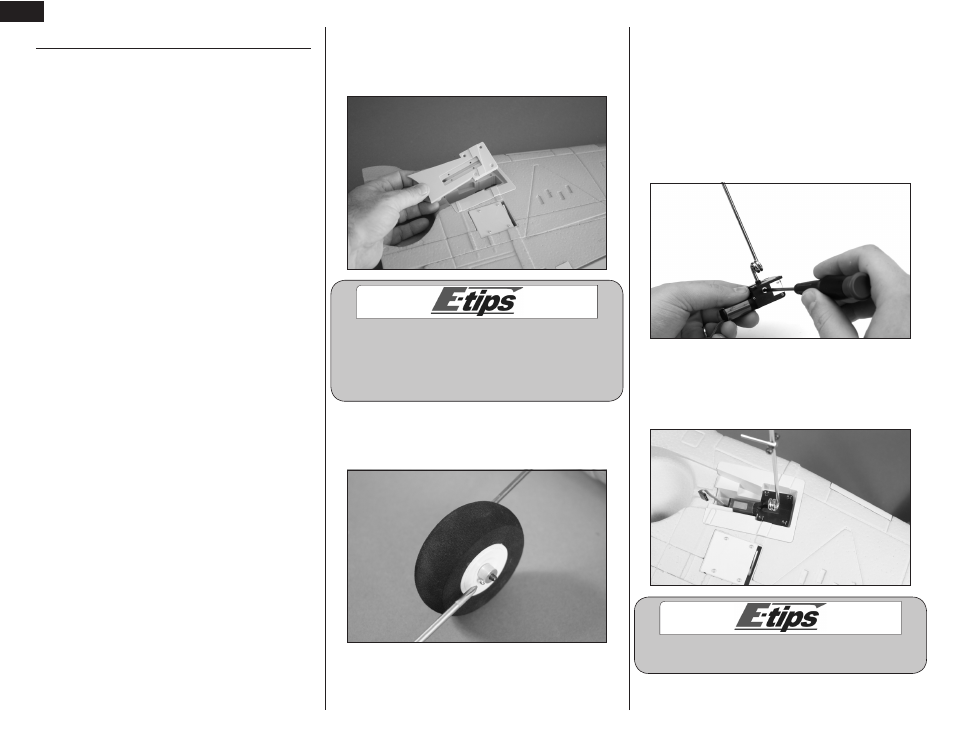

1. Use a #1 Phillips screwdriver to remove the four

3mm x 25mm machine screws that secure the fixed

gear adapter in the wing. Remove the adapter from

the wing.

If you are upgrading from fixed gear to retracts,

you can remove the complete assembly with the

same four screws. Set the fixed gear aside just in

case you have a retract failure. You can always

reinstall the fixed gear to keep your model flying.

2. Use a #1 Phillips screwdriver to loosen the 3mm

x 4mm machine screw that secures the wheel collar.

Remove the wheel and wheel collar at this time.

3. Use the radio system to move the landing gear to

the down position. Loosen the setscrew in the retract

unit so that the gear strut can be removed from the

retract unit. Push the trunnion through the retract

assembly and reinstall in reverse orientation so that

the setscrew will be opposite the pre-ground flat spot

on the gear strut. Position the axle so it is 4

5

/

16

-inch

(109mm) as shown. Lightly tighten the screws in the

axle with a 2.5mm hex wrench at this time, as it will

require positioning in the following steps.

4. Place the retract mechanism in the wing. Check

that the holes align with those in the gear pocket.

Note that installing two screws lightly diagonally

from one another will align the retract unit perfectly.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.