Testing - reduced pressure zone assemblies, Watts tk-dl, Test no. 1 - relief valve – Watts 994 User Manual

Page 7: Test no. 2 - test no. 2 check valve, Test no. 3 - test no. 1 check valve

7

Testing - Reduced Pressure Zone Assemblies

Watts TK-DL

The following Test Procedure is one of several that is recognized

throughout the United States for testing Backflow Preventers.

The following procedure is not a specific recommendation. The

Watts series of test kits are capable of performing any of the recog-

nized Backflow test procedures.

For additional testing information refer to literature IS-TK-DL, IS-TK-9A and IS-TK-99E

A. Open TC #4 and flush test cocks No’s. 1, 2 and 3 on BF assem-

bly, then close TC #4.

B. Turn tester on (before connecting hoses). Tester must read all

zeros. Close VA and VB.

Test No. 1 - Relief Valve

1. Install high-side hose between TC #2 and tester connection A.

2. Install low-side hose between TC #3 and tester con nec tion B.

3. Open TC #3 then VB. Now open TC #2 slowly, then VA. Close

VA then VB.

4. Close #2 shutoff valve.

5. Observe the apparent first check valve differential pressure (A - B).

6. Install bypass hose between VA and VB. Open VB and bleed air

by loosening hose connection at VA. Tighten hose connection

and close VB.

Push - Print Head (wait) then Push - Start Test

7. Open VA, then slowly open VB (no more than 1⁄4 turn). When

relief valve drips, push the “hold button” for 2 seconds. Record

reading (must be 2 PSID or more).

Push - Stop Test

8. Close VA and VB.

Test No. 2 - Test No. 2 Check Valve

9. Install bypass hose between VA and TC #4. Open VA, then

bleed air by loosening hose connection at TC #4. Tighten hose

connection. Close VA.

Push - Start Test

10. Open VB to reestablish pressure within the “zone”. Close VB.

11. Open TC #4, then open VA. If relief valve does not drip, record

second check valve as “close tight”.

Test No. 3 - Test No. 1 Check Valve

12. Open VB to reestablish first check valve dif fer en tial pressure.

Close VB. Record pressure differential.

Stop Test (Push Stop Test twice)

13. Close test cocks and remove tester, return as sem bly to nor mal

operating condition.

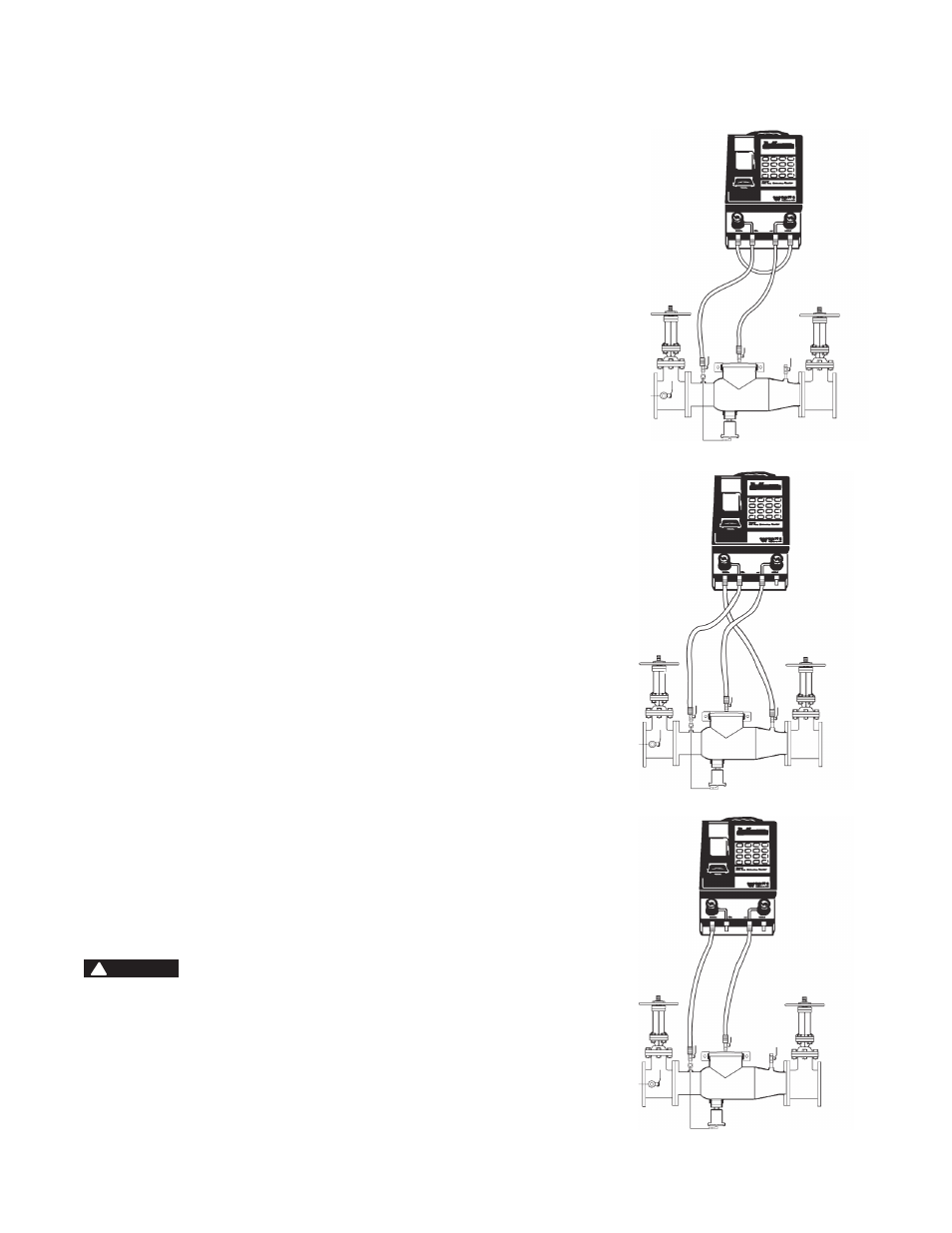

RPZ

Test 1

RPZ

Test 2

RPZ

Test 3

Series 994

A B

VA

VB

WARNING

!

it is important that this device be tested periodically in com pli ance

with local codes, but at least once per year or more as ser vice con

di tions warrant. if installed on a fire sprinkler system all me chan i cal

checks, such as alarm checks, single checks and backflow preventers

should be inspected internally every one to five years in accordance

with nFpa 13 a and nFpa 25

Series 994

Series 994

A B

VA

VB

A B

VA

VB