Servicing first and second checks, Servicing the first check, Use extreme caution when servicing the first check – Watts 994 User Manual

Page 5

5

Servicing First and

Second Checks

Series 994/994RPDA

8" and 10" (200 – 250mm)

1. Slowly open all ball valves to relieve air and water pressure.

Loosen bolts on groove coupler and remove groove couple and

cover plate from valve body.

2.

#1 CHECK

Using a

9

⁄

16

" socket wrench or nut driver, remove the four nuts

from the #1 check studs

(see fig. 1). Using two hands, place

them at 12 o’clock and 6 o’clock, wiggle the check assembly free.

Remove through access port with back of clapper first with spring

end down. Pull check assembly out of main body. Inspect seats

and clap per seal ing surfaces. (See page 6.)

#2 CHECK

After loosening bolts with a

9

⁄

16

" socket, remove bolts completely.

Using the centerline access bar, spin the check assembly from the

9 o’clock position to the 12 o’clock position, then (without letting

go of the ac cess bar) push the cam assembly slightly down stream

so that the clapper is now parallel to the valve body. Now bring

the check as sem bly through the check retaining wall. Leave the

check assembly par al lel to the valve body. Pull the check assem-

bly through the access port.

3. Using a

3

⁄

8

" nut driver or a piece of small diameter pipe, place

on the check arm torsion spring and move away from and move

away from and around the torsion spring retaining bracket so as

to relieve the tor sion spring tension. This will allow the check arm

to move free ly, en abling you to inspect the clapper face and check

seat. Thor ough ly clean the seat area and clapper sealing surfaces,

check arms, and O-rings for damage, nicks, and debris. If dam-

aged, in stall a new check as sem bly and or O-ring.

4. Before reinstallation of check assembly, thoroughly clean O-ring

groove and lubricate O-ring with F.D.A. approved lubricant.

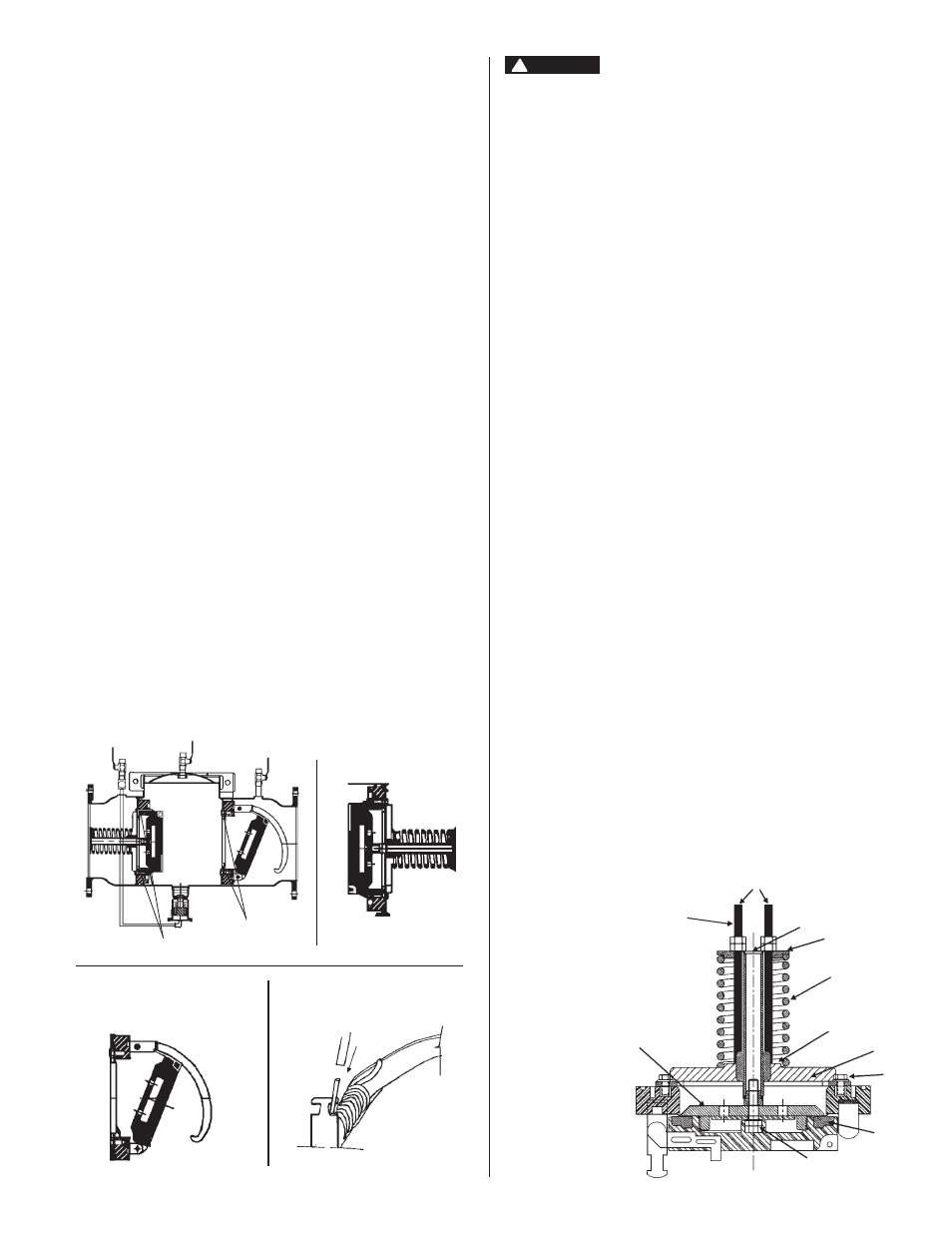

Figure 1

Check Studs

Check Studs

Figure 3

#2 Cam-Check DC & RP

Figure 2

#1 Cam-Check RP

Figure 4

Removing Check Assemblies (Before servicing

be certain shutoff valves are closed)

1. After removing the first check from the backflow valve body, place

on a flat surface with the coil spring facing up.

2. In order to gain access to the seat and clapper rubber ring, you

must compress the spring (#3) that surrounds the clapper shaft

(#1). To do so, you must place the

3

⁄

8

" threaded rod through two

holes of the spring retaining plate #2.

3. After placing the

3

⁄

8

” all-thread rod through the spring retaining

plate, Screw the threaded rod into the holes (#4) at the base of

spider (#5 next to shaft). Be sure to use two nuts on the threaded

rod to tighten them into the holes. The depth of the threaded

holes should be approximately

1

⁄

2

". This operation will require you

to use two piec es of threaded rod (see drawing below).

4. Compressing the spring. To do so you need to loosen the top

3

⁄

8

”

nut and back it off without unthreading the threaded rod from the

spider. Place a box end wrench or crescent wrench on the

3

⁄

8

”

nut clos est to the spring retaining plate and tighten. Tighten both

thread ed and nut evenly; put a few turns on one threaded rod nut

and a few turns on the other.

5. During compression, the clapper will slowly move up, away from

the seat. To examine the seat, continue spring compression un til

the clapper has moved approximately 1" from the seat. This will

allow de bris to be removed and or the seat to be examined.

6. To unload the spring compression, loosen the all-thread and then

double nut the all-thread and unscrew the rod from the spider and

shaft base.

1. Shaft

2. Spring retaining plate

3. Spring

4.

3

⁄

8

” threaded hole (maintenance)

5. Spider

6. Spider retaining bolt

7. Seat ring

8. Clapper to shaft bolt

9. Seat ring retainer

1

2

3

4

5

6

3

⁄

8

- 16

var.

Threaded Rod

7

8

9

#1 Check

Valve 8" & 10"

(200 & 250mm)

DANGER

!

Use extreme caution when servicing the first check!

Servicing the

First Check

To inspect the seat and clean the seat and

clapper washer:

To disassemble the first check, you will need

the following:

• Two pieces of

3

⁄

8

" threaded rod (approximately 14" long)

• Adjustable crescent wrench

• Pipe wrench or channel lock pliers