Basic installation instructions, Series 994 reduced pressure zone assemblies, Location and installation considerations – Watts 994 User Manual

Page 2

2

Location and Installation Considerations

1. Backflow preventers must be installed in high-visibility lo ca tions in

order to allow for immediate notice of telltale discharge or oth er

mal func tion. This location should also facilitate testing and ser vic-

ing and protect against freezing and vandalism.

2.

Installation procedures must comply with all state and lo cal

codes.

3. Installing a backflow preventer in a pit or vault is not rec om mend-

ed. An air gap be low the relief port must be maintained so as to

avoid flood ing and sub mer sion of the assembly, which may lead

to a cross-connection. Watts recommends installations in doors

or above ground in an in su lat ed enclosure. (Refer to literature

ES-WB)

4. A strainer should be installed ahead of the backflow pre ven ter to

protect the discs from unnecessary fouling.

CAUTION

!

Do not install a strainer ahead of the backflow pre ven ter on

seldom-used, emergency water lines (i.e. fire sprinkler lines). The

strainer mesh could potentially become clogged with debris pres-

ent in the water and cause water blockage during an emer gen cy.

5. Normal discharge and nuisance spitting are ac com mo dat ed by

the use of a Watts air gap fitting and a fabricated indirect waste

line. Floor drains of the same size

MUST be provided in case of

ex ces sive discharge.

6. When a Series 994 backflow preventer is installed for dead-end

ser vice applications, dis charge from the relief vent may occur

due to wa ter supply pressure fluc tu a tion during static no-flow

con di tions. A check valve may be re quired ahead of the backflow

preventer.

7.

ASSEMBLY: If the backflow preventer is disassembled dur ing

in stal la tion, it

MUST be reassembled in its proper order. The gate

valve with the test cock is to mounted on the inlet side of the

back flow pre ven ter. The test cock must be on the inlet side of the

wedge. Failure to reassemble correctly will result in possible wa ter

damage due to excessive discharge from the relief port/vent and

possible mal func tion of the backflow preventer.

8. Prior to installation, thoroughly flush pipe line to re move any for-

eign matter.

9.

START UP at Initial Installations and After Servicing: The down-

stream shutoff should be closed. Slowly open upstream shutoff

and allow the backflow preventer to fill slowly. Bleed air at each

test cock. When backflow preventer is filled, slowly open the

down stream shut off and fill the water supply system. This is nec-

es sary to avoid water hammer or shock damage.

NOTICE

Assembly body should not be painted.

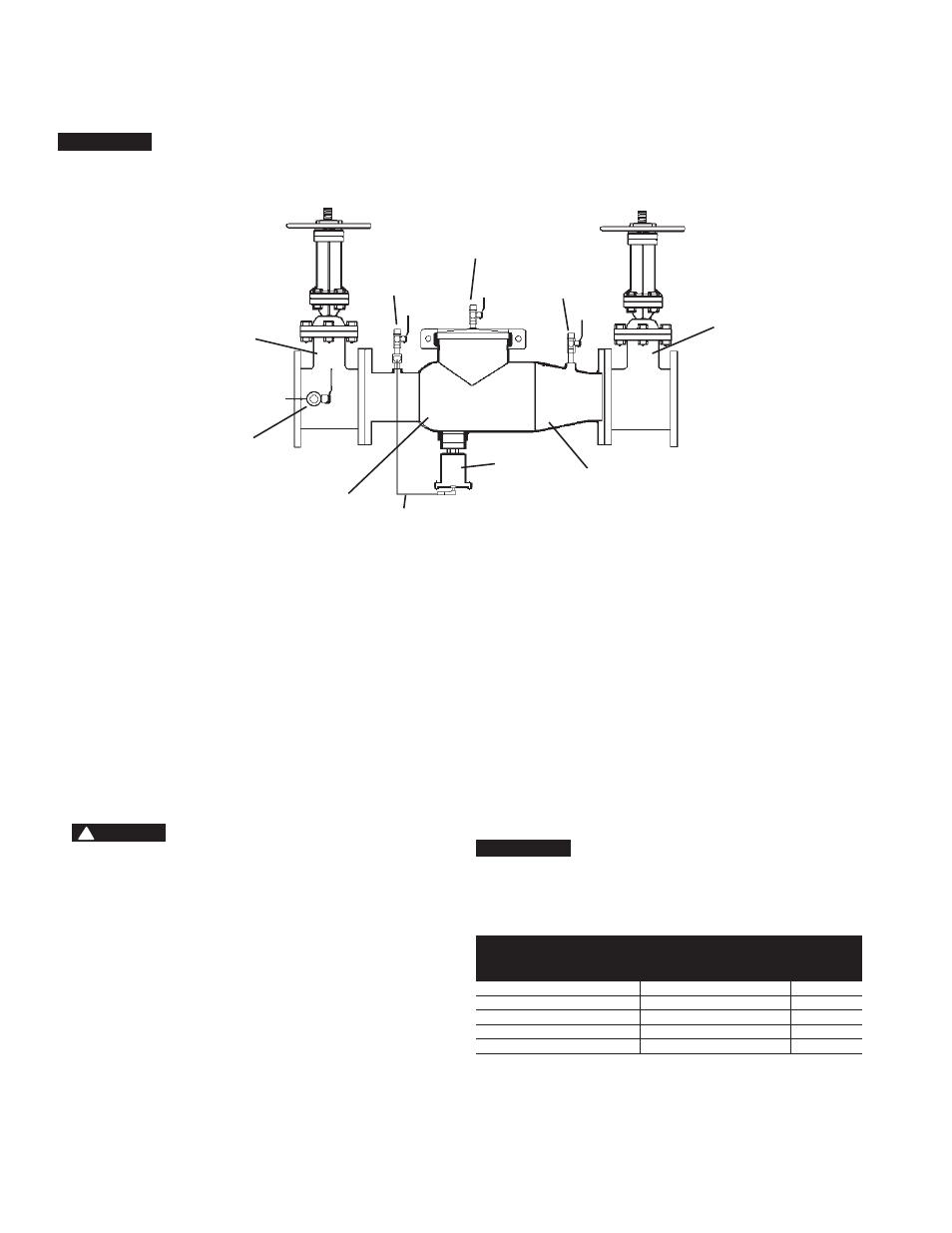

Figure 1

ValVE SizE

Typical FlOw RaTES aS

SizEd By FlOOR dRain

ManuFacTuRERS

dRain SizE

in.

mm

2

1

⁄

2

65

55 gpm

2

3

80

112 gpm

3

4

100

170 gpm

4

6, 8, 10

150, 200, 250

350 gpm

5

Basic Installation Instructions

Series 994 Reduced Pressure Zone Assemblies

#2 Test Cock

#3 Test Cock

#4 Test Cock

Outlet

Shutoff

#2 Check

Relief

Valve

Sensing

Line

1st Check

#1 Test Cock

Inlet Shutoff

Valve

NOTICE

The flange gasket bolts for the gate valves should be re tight ened during

in stal la tion as the bolts may have loos ened due to storage and ship ping.