Test no. 1 - relief valve, Test no. 2 - test no. 2 check valve, Test no. 3 - test no. 1 check valve – Watts TK-DL User Manual

Page 5

5

The following Test Procedure is one of several that is recognized throughout the United

States for verification of the functioning of Backflow preventers.

The following procedure is not a specific recommendation. The Watts series of test kits are

capable of performing any of the recognized Backflow test procedures.

A. Open TC #4 and flush test cocks Nos. 1, 2 and 3 on BF as-

sembly, then close TC #4.

B. Turn tester on (before connecting hoses). Tester must read all

zeros. Close VA and VB.

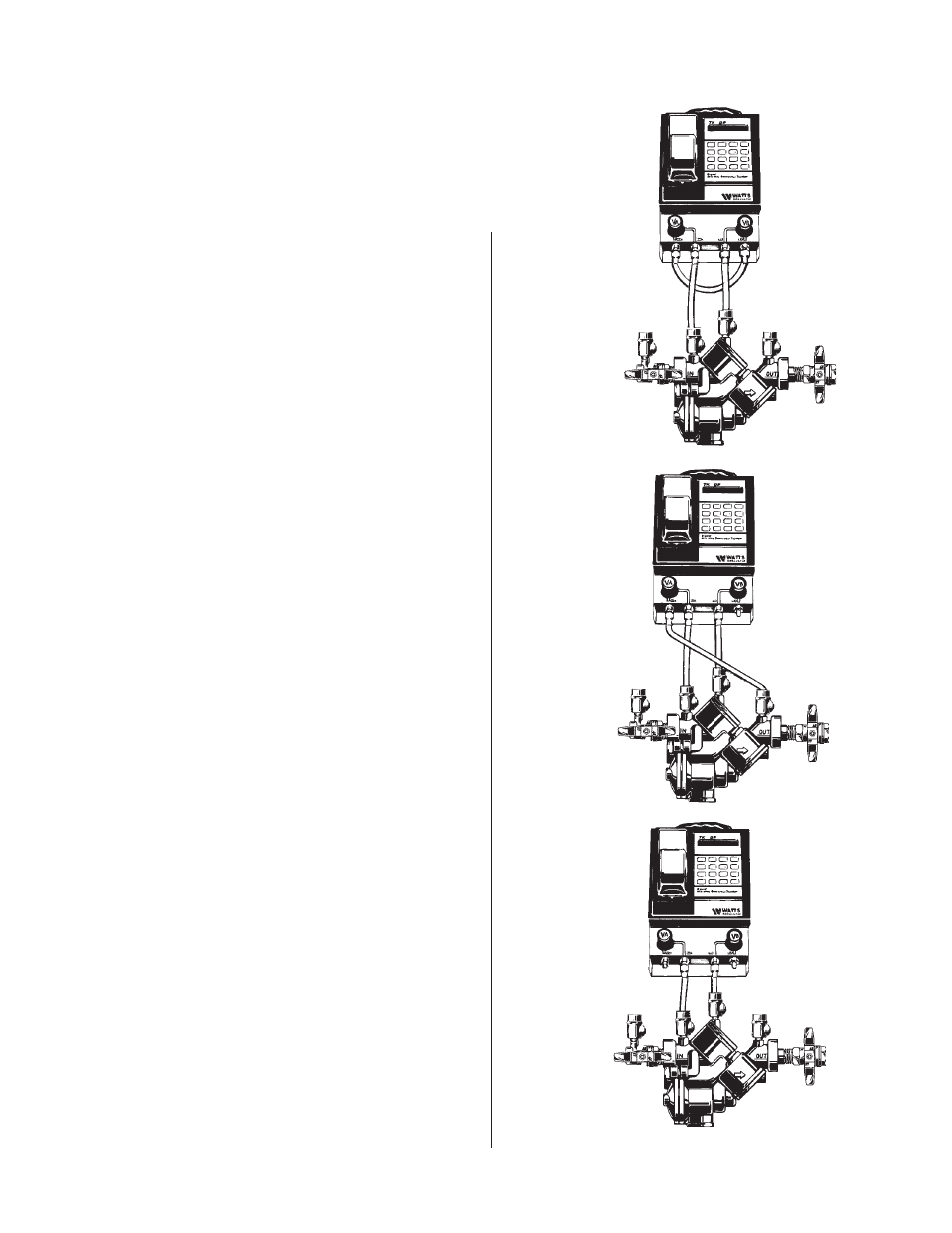

Test No. 1 - Relief Valve

1. Install high side hose between TC #2 and tester connection A.

2. Install low side hose between TC #3 and tester connection B.

3. Open VB then TC #3. Now open VA then TC #2 slowly.

Close VA then VB.

4. Close #2 shutoff valve.

5. Observe the apparent first check valve differential pressure

(A - B).

6. Install bypass hose between VA and VB.

Open VB and bleed air by loosening hose connection at VA.

Tighten hose connection and close VB.

Push - Print Head (wait) then Push - Start Test

7. Open VA, then slowly open VB (no more than 1⁄4 turn). When

relief valve drips, push the “hold button for 2 seconds. Record

reading (must be 2 PSID or more).

Push - Stop Test

8. Close VA and VB.

Test No. 2 - Test No. 2 Check Valve

9. Install bypass hose between VA and TC #4.

Open VA, then bleed air by loosening hose connection at TC

#4. Tighten hose connection. Close VA.

Push - Start Test

10. Open VB to reestablish pressure within the “zone”. Close VB.

11. Open VA the TC #4. If relief valve does not drip,

record second check valve as “closed tight”.

12. Close VA and TC #4 and remove bypass hose.

Test No. 3 - Test No. 1 Check Valve

13. Open VB to reestablish first check valve differential pressure.

Close VB. Record pressure differential.

Stop Test (Push Stop Test twice)

14. Close test cocks and remove tester, return assembly to nor-

mal operating condition.

V H

L

V

1

2

3

4

V

H

L

V

1

2

3

4

1

2

3

4

V H

L

V

Test Procedure for Reduced Pressure Zone Assemblies