Test procedure for pressure vacuum breakers – Watts TK-DL User Manual

Page 2

2

The following Test Procedure is one of several that is recognized

throughout the United States for verification of the functioning of

Backflow preventers.

The following procedure is not a specific recommendation. The

Watts series of test kits are capable of performing any of the

recognized Backflow test procedures.

NOTICE

For both of the following tests, the TK-DL must be held at the

same level as the assembly being tested.

A. Flush TC #1 and #2.

B. Turn tester on (before connecting hose). Tester

must read all zeros. Close VA and VB.

Test No. 1 - Air Inlet

1. Install high side hose between TC #2 and tester connection

A.

2. Open VA then TC #2. Bleed hose, then close VA.

3. Close shutoff valve #2 then #1.

Push - Print Head (wait) then Push -

Start Test

4. Slowly open VA when air inlet float opens, push “hold” button

for at least 2 seconds.

Record differential reading (must be 1 PSID or more). Close

VA.

Push - Stop Test

5. Close TC #2 and remove hose.

6. Open shutoff valve #1.

Test No. 2 - Test Check Valve

7. Install highside hose between TC #1 and tester connection

A.

8. Open VA then TC #1. Bleed hose, then close VA.

9. Close shutoff valve #1.

Push - Start Test

10. Open TC #2. When flow of water out of TC #2 stops, the

differential reading is the pressure drop. Record (must be 1

PSID or more).

Stop Test (Push Stop Test twice)

11. Close test cocks and remove tester. Return assembly to

normal operating condition.

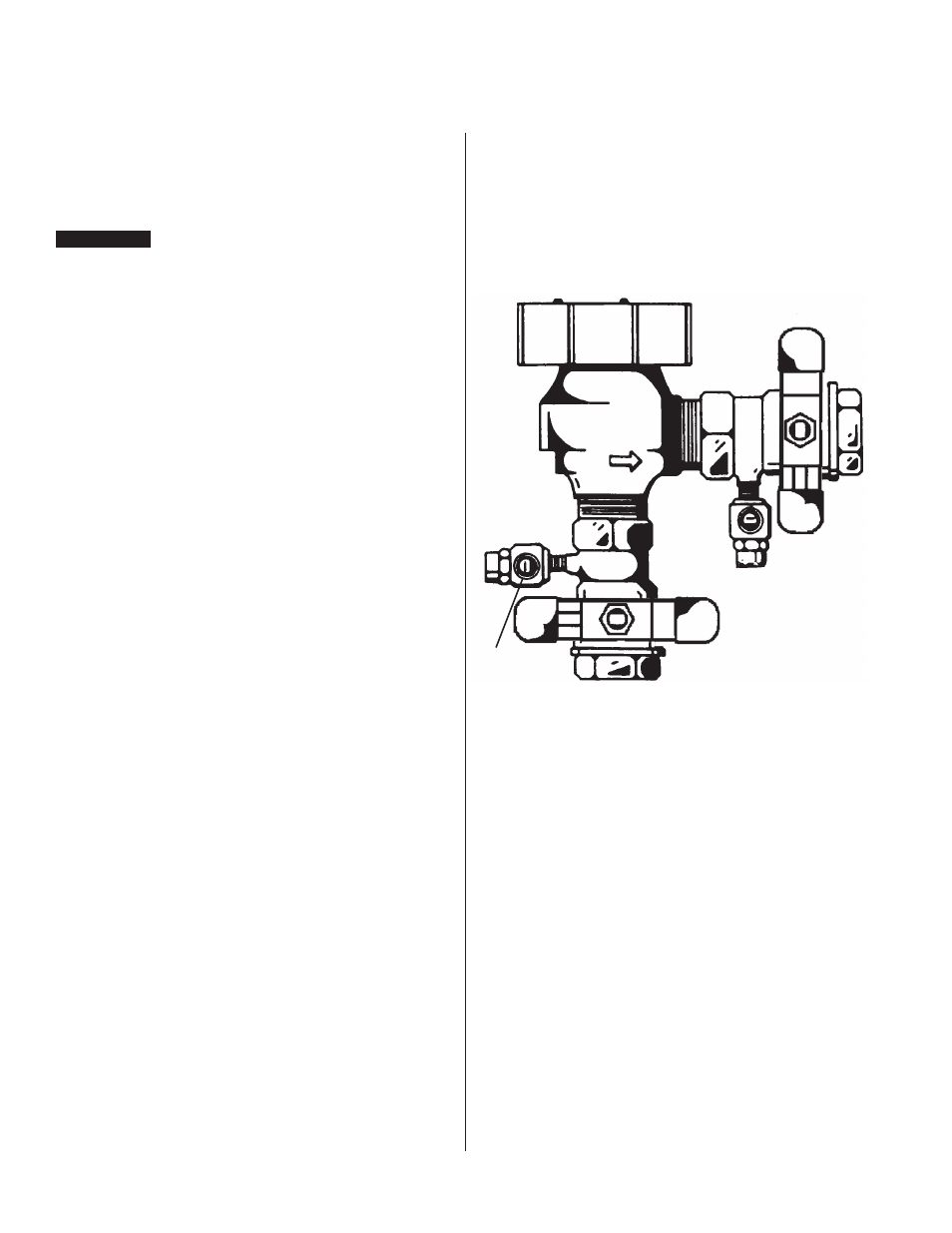

Test Cock No. 1

Test Cock No. 2

800M4-QT/LF800M4-QT

Test Procedure for Pressure Vacuum Breakers