Test no. 1 - test no. 1 check valve, Test no. 2 - test no. 2 check valve – Watts TK-DL User Manual

Page 4

4

The following Test Procedure is one of several that is recognized throughout the United States for verification of the functioning of

Backflow preventers.

The following procedure is not a specific recommendation. The Watts series of test kits are capable of performing any of the recog-

nized Backflow test procedures.

A. Flush all test cocks.

B. Turn tester on (before connecting hoses).

Tester must read all zeroes. Close VA and VB.

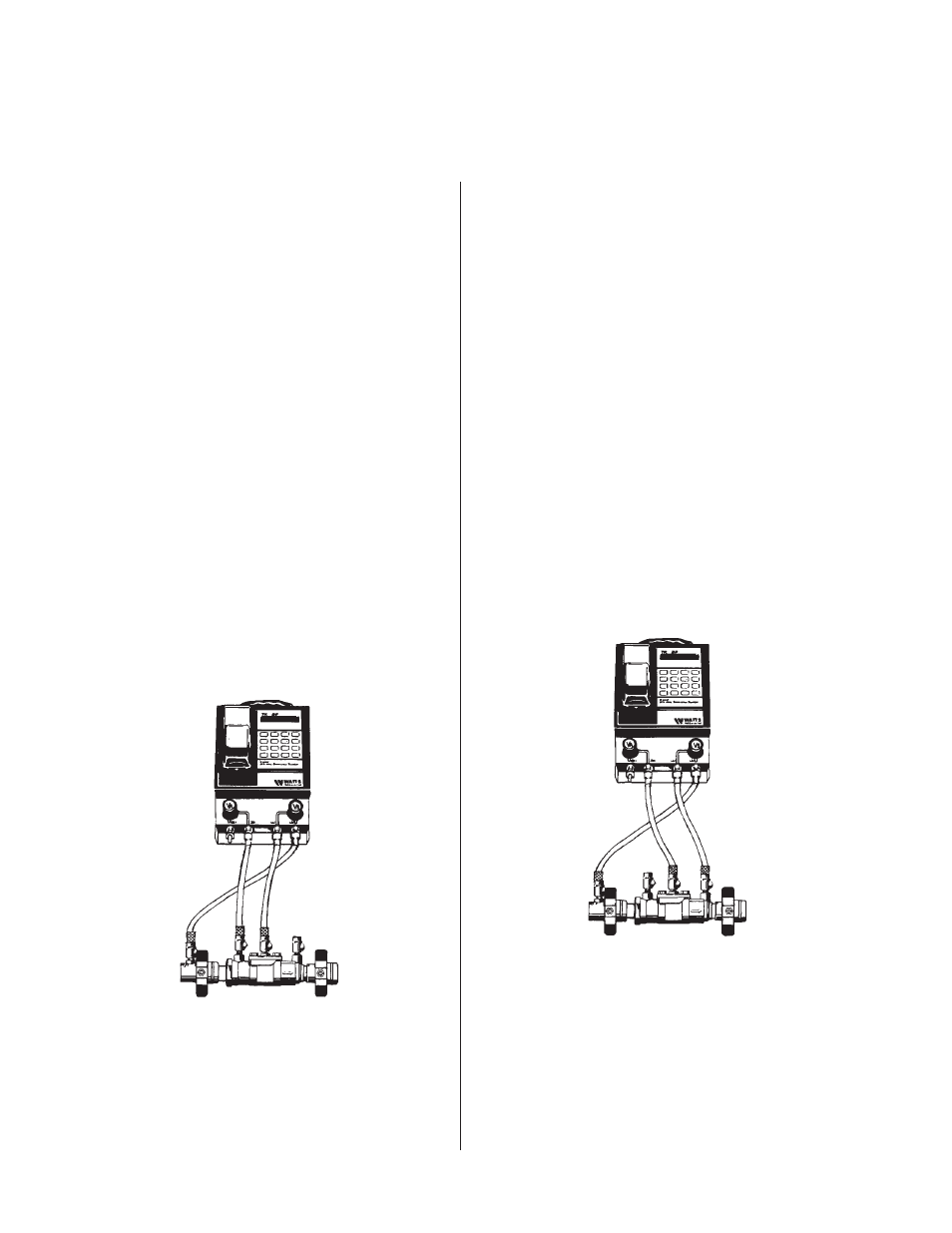

Test No. 1 - Test No. 1 Check Valve

1. Install high side hose between TC #2 and tester connection

A.

2. Install low side hose between TC #3 and tester connection B.

3. Open VA then TC #2, bleed hose, then close VA.

4. Open VB then TC #3, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1. Open TC #1

and bleed by loosening hose connection at VB. Tighten

hose connection, fully open VB.

Push - Print Head (wait) then Push - Start Test.

6. Close shutoff valve #2 then #1.

7. Slowly open VA and lower high side pressure about -2 PSID

below the low side pressure (differential reading about -2.0

PSID). Close VA. If reading is maintained, record as “tight”. If

reading returns to 0 and the pressure A increases to pressure

B, the check is recorded as leaking. If the reading returns to

+PSID, No. 2 shutoff valve is leaking excessively and must be

replaced to test the valve.

8. Close all test cocks, remove hoses from TC #2 and TC #3

and TC #1. reopen shutoff valve #1. Proceed to Test No. 2.

Push - Stop Test.

Test No. 2 - Test No. 2 Check Valve

1. Install high side hose between TC #3 and tester connection A.

2. Install low side hose between TC #4 and tester connection B.

3. Open VA then TC #3, bleed hose, then close VA.

4. Open VB then TC #4, bleed hose, then close VB.

5. Install a bypass hose between VB and TC #1.

Loosen hose at VB, open TC #1 and bleed, retighten hose

connection.

Push - Start Test.

6. Close shutoff valve #1.

7. Slowly open VA and lower high side pressure about -2 PSID

below the low side pressure (differential reading about -2.0

PSID). Close VA. If reading is maintained, record as “tight”. If

reading returns to 0 and the pressure A increases to

pressure B, the check is recorded as leaking. If the reading

returns to + PSID, No. 2 shutoff valve is leaking excessively

and must be replaced to test the valve.

Push - Stop Test.

V

H L

V

1

2

3

4

1

2

3

4

V

H L

V

Test Procedure for Double Check Valve Assembly (DC)