Coolant – Bird Technologies 8650B Series User Manual

Page 21

Installation

9

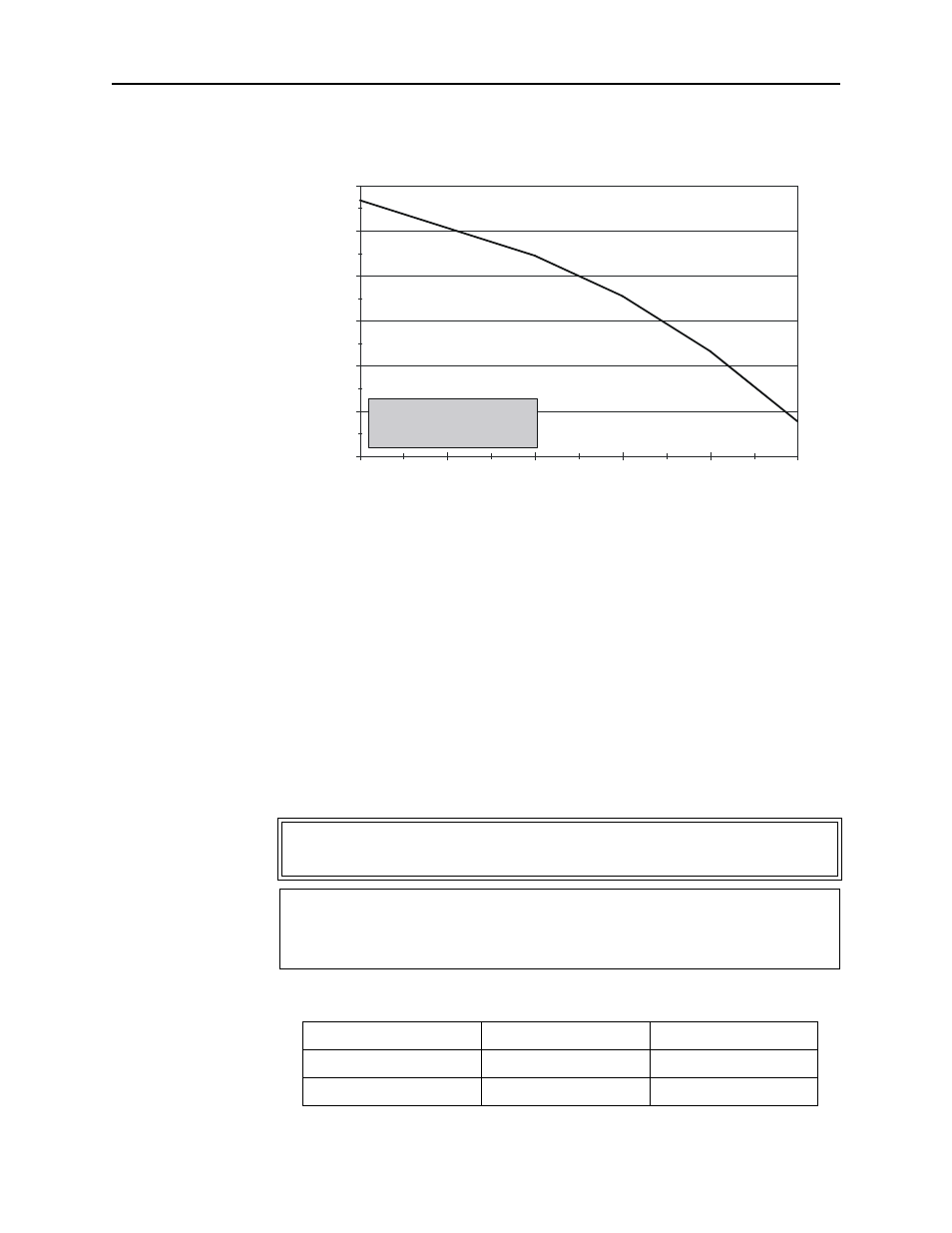

Figure 6 Freezing Point of Ethylene Glycol /Water Mixture °C

Coolant

Before shipment, the Moduload is drained of coolant to avoid possible damage

from freezing in transit. The system must be refilled with coolant before it can

be put into operation. The unit operates with 17 quarts (16.1 liters) of coolant.

The load’s electrical and thermal performance can become impaired by impu-

rities or additives in the coolant. Impurities which accumulate as scale on the

resistor surface are especially damaging.

The coolant must be either; distilled water or a mixture of distilled water and

ethylene glycol. Distilled water is the primary coolant for the Bird 8650. Eth-

ylene glycol should be added to prevent bacterial growth and freezing.

Note:

10% – 35% ethylene glycol is recommended. Using at least

10% will prevent bacteria growth and 35% will protect against freezing

to –20°C. Table 5 and Table 6 show the coolant’s freezing point for a

given percentage of ethylene glycol in the mix.

To ensure proper mixing add the water first, then the ethylene glycol

The following example shows the weights to make a 65% distilled water to 35%

ethylene glycol mixture in 5 and 55 gallon quantities:

-60

-50

-40

-30

-20

-10

0

Te

m

per

at

ur

e,

D

egr

ee

s

C

el

si

u

s

10 20 30 40 50 60

% Ethylene Glycol

Specifications for ethylene glycol

having: specific gravity 1.125 @

32°F; specific heat .575 @ 68°F

WARNING

Ethylene glycol is toxic. Do not take internally. Avoid contact with eyes,

skin, and clothing. Avoid breathing vapor. Wash thoroughly after handling.

CAUTION

Use only distilled water or the supplied ethylene glycol as coolant. Do not

use tap water, automotive antifreeze, sealants, or leak stopping material.

Use of these materials will damage the instrument and void all warranties.

5 Gal. (18.9 L)

55 Gal. (208.2 L)

Distilled Water

28.0 lb (12.7 kg)

310 lb (140.6 kg)

Ethylene Glycol

15.2 lb (6.9 kg)

167 lb (75.7 kg)