Rf connector – Bird Technologies 8327-300 User Manual

Page 22

s Ohmmeter with an accuracy of ±1% at 50 Ohms.

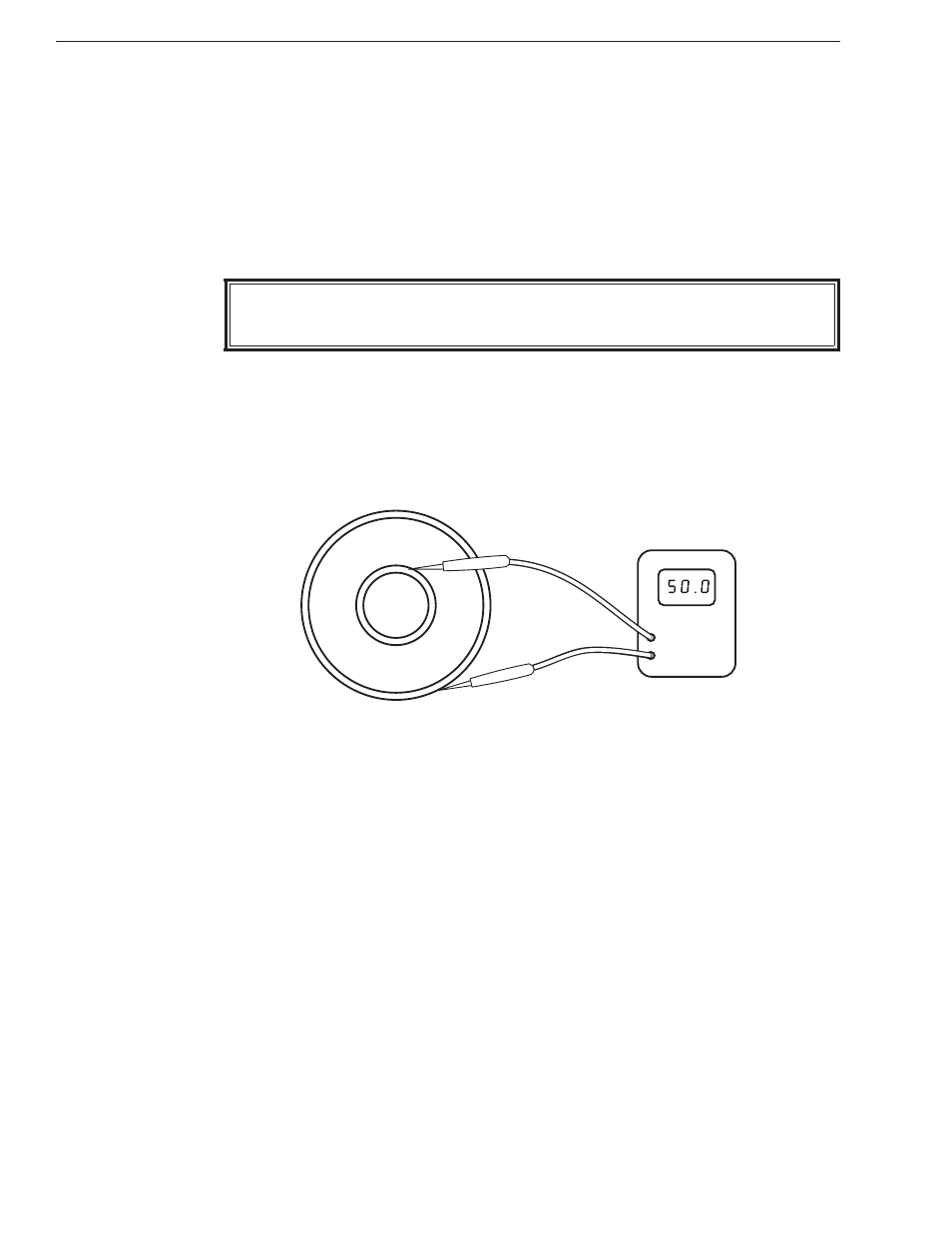

s Temperature of the load between 20°C to 25°C (68°F to 77°F)

Accurate measurement of the dc resistance between the inner and outer conductors

of the RF input connector will provide a good check of the condition of the load

resistor. Checking the dc resistance is simply used to measure a change in the

condition of the resistor over time. The tracking of the dc resistance must start

before

the resistor is first put into service. Perform the following steps and record the value

for future comparison. Check and record the resistance of the load periodically

according to use.

WARNING

Never attempt to disconnect the equipment from the transmission line while RF power is

being applied. Leaking RF energy is a potential health hazard.

1. Turn off RF power and interlock circuitry before any electrical dis-

connection’s are made.

2. Disconnect the RF coaxial line.

3. Connect the multimeter test leads across the center and outer con-

ductor of the load resistor. Refer to figure 5.

4. Record the value of the resistance

before the load is put into service.

Compare subsequent values with the latest reading. If the values

vary more than 2 ohms, this could be an indication of a failing

resistive element.

+

Note: It is recommended that this resistance check be performed each time the

load is to be used.

RF Connector

Tool required:

s Screwdriver

The following paragraphs outline the component removal and replacement procedure.

The connector is a “Quick-Change” design which permits easy interchange with the

use of only a screwdriver. This process does not interfere with the essential coaxial

continuity of the attenuator RF input, out put, or the coolant oil seals. For replace-

ment, proceed as follows:

1. Remove and retain the four screws from the corners of the RF

connector.

Figure 5

Meter Lead

Placement

Bird Model 8327-300 Attenuator

12