Maintenance, Safety considerations, Power supply load units – Rockwell Automation T3512 ICS Regent Power Supply Modules User Manual

Page 6

I/O Power Supply Modules (T3510, 11, and 12)

6

Industrial Control Services

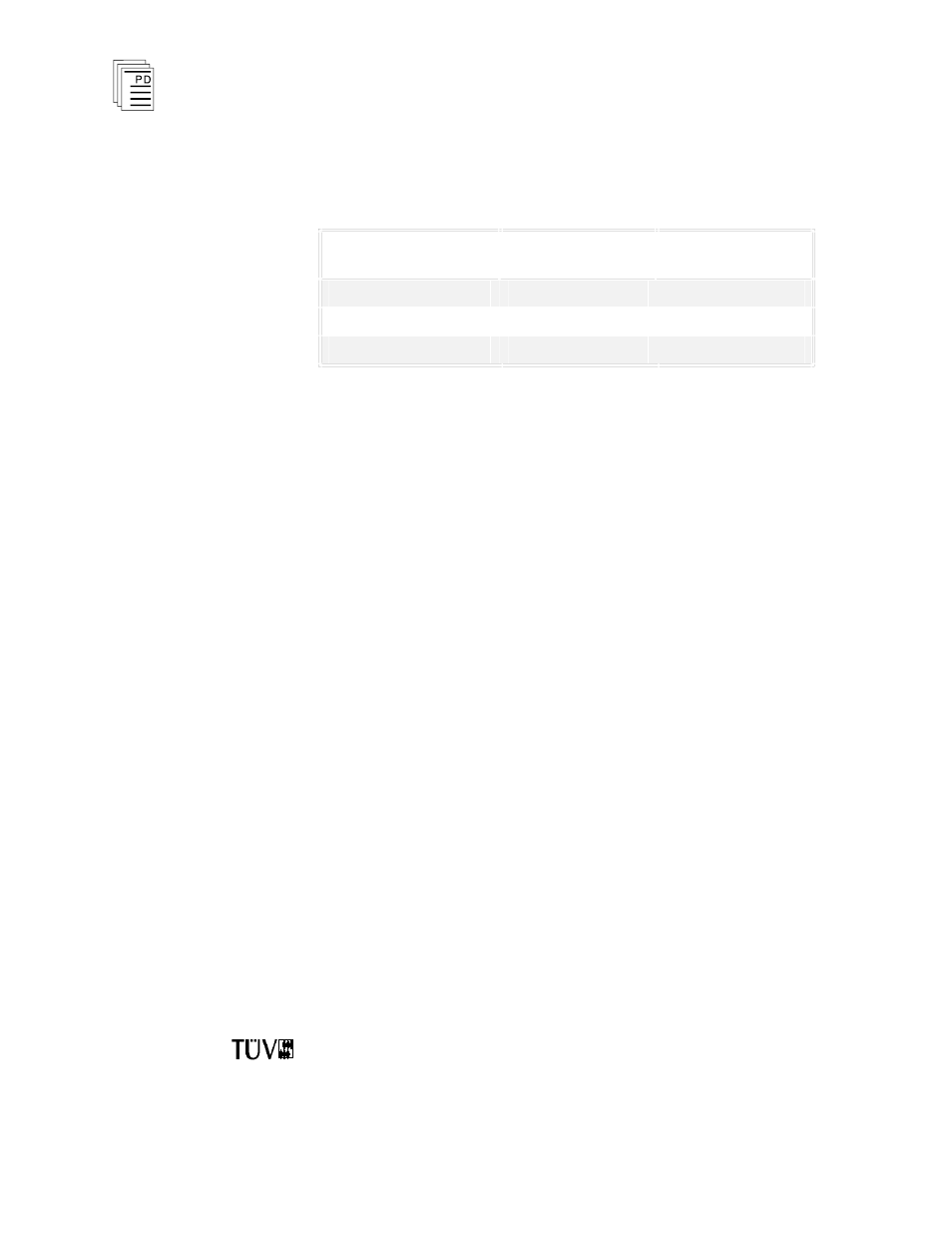

Use Table 1 to verify voltage compatibility for your I/O power

supply chassis and I/O power supply modules.

Table 1. Matching Input Power Voltages.

Input Power Voltage

I/O Power Supply

Chassis

I/O Power Supply

Module

110 VAC

T3500

T3510

220/240 VAC

T3501

T3511

24 VDC

T3502

T3512

Power Supply Load Units

Power supply unit loading is based on the number of I/O

modules in the chassis and the load imposed by each I/O

module. Load units for each I/O module are shown in that

module’s product description and specification sheet under the

heading “Safetybus Power.” I/O power supply load units are

shown on page 7, as “Available Load Units.”

Calculating the number of load units in your system will help

you determine the number of I/O power supplies your system

will need. For economic power distribution, and to avoid

overloading individual power supply units, power supply

loading should be calculated when configuring systems.

Maintenance

No periodic maintenance or calibration is required for I/O

power supply modules. There are no user replaceable parts

inside these modules.

When an I/O power supply module fails, it can be hot-replaced

without disrupting system operations. Main power wiring and

I/O power cables (connected to the chassis) are not disturbed

during module replacement.

Safety Considerations

The T3510 (110 VAC) and T3512 (24 VDC) I/O power supply

modules are TÜV certified for Risk Class 5 safety critical

applications. Model T3511 (220 VAC) is excluded as it does