Application, Module configuration, T8403 complex equipment definition – Rockwell Automation T8403 Trusted 24V dc Digital input Module - 40 Channel User Manual

Page 16

Trusted

TM

Module T8403

Issue 15 Jun 13

PD-T8403

16

3. Application

3.1. Module Configuration

There is no configuration required to the physical input module. All configurable characteristics of the

module are performed using tools on the EWS and become part of the application or system.ini file

that is loaded into the TMR Processor. The TMR Processor automatically configures the input module

after applications are downloaded and during Active/Standby changeover.

The IEC1131 TOOLSET provides the main interface to configure the input module. Details of the

configuration tools and configuration sequence are provided in PD-8082B. There are three procedures

necessary to configure the input module. These are:

1. Define the necessary I/O variables for the field input data and module status data using the

Dictionary Editor of the IEC1131 TOOLSET.

2. Create an I/O module definition in the I/O Connection Editor for each I/O module. The I/O

module definition defines physical information, e.g. Chassis and Slot location, and allows

variables to be connected to the I/O channels of the module.

3. Using the Trusted

TM

System Configuration Manager, define custom LED indicator modes,

per-channel threshold levels and noise filtering, and other module settings.

3.2. T8403 Complex Equipment Definition

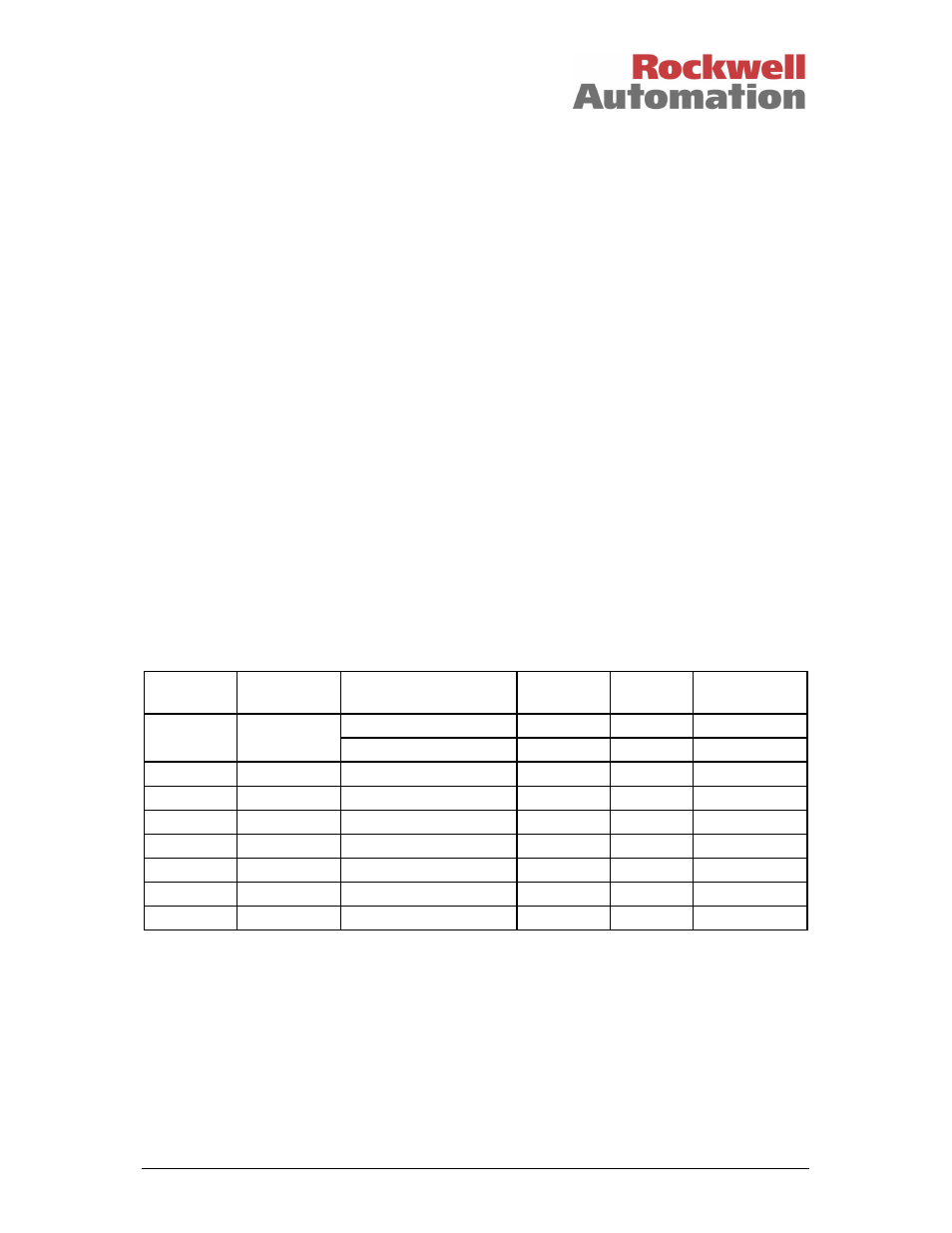

The T8403 I/O Complex Equipment Definition includes 8 I/O boards, referenced numerically by Rack

number:

Rack

I/O Board

Description

Data Type

Direction

No. of

Channels

1

DI

OEM Parameters

-

-

-

Field Input Status

Boolean

In

40

2

STATE

Field Input State

Integer

In

40

3

AI

Input voltage

Integer

In

40

4

SPARE

Not used

Integer

-

16

5

LINE_FLT

Line Fault Status

Boolean

In

40

6

DISCREP

Channel Discrepancy

Integer

In

3

7

HKEEPING

Housekeeping Registers Integer

In

51

8

INFO

I/O Module Information

Integer

In

11

Table 3 Complex Equipment Definition

There are two OEM parameters included in the first rack (DI Board). These OEM parameters define

the primary module position; declaring the module’s chassis and slot location. There is no need to

define the secondary module position within the IEC1131 TOOLSET. Where systems may be required

to start-up with a module in the secondary position as the active module, e.g. primary module is not

installed when application is started, the secondary module’s position should be declared in the module

definition of the System Configuration Manager.