Step 15: apply final torque to all connections, Step 16: install the ac input cables, Step 17: complete the circuit tests – Rockwell Automation 20D PowerFlex 700S and 700H Frame 12 DC Bus Connector Kit User Manual

Page 28

28

PowerFlex® 700S and 700H Frame 12 DC Bus Connector Kit

Step 15: Apply Final Torque

to All Connections

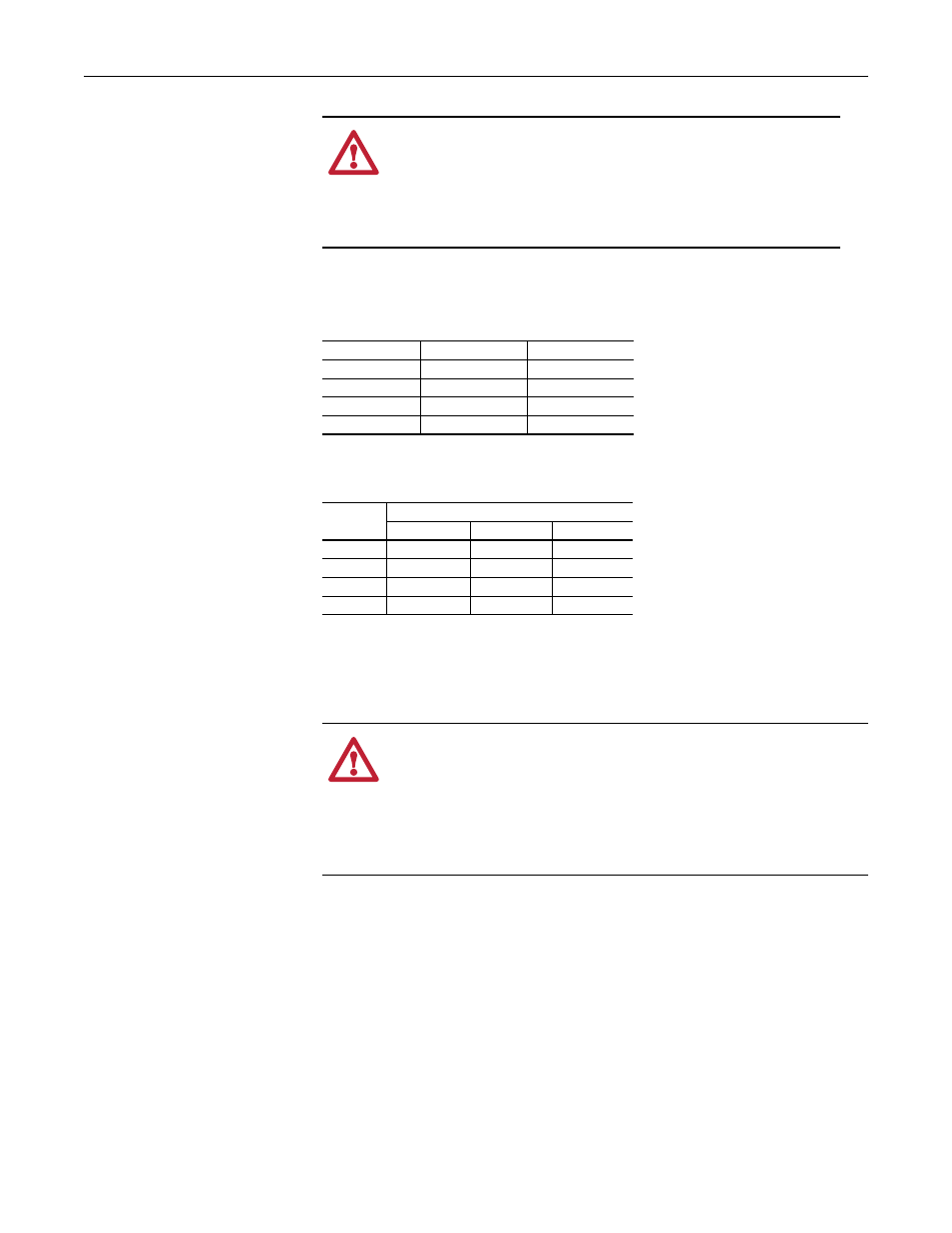

Important: Prior to and after applying the final torque to all connections, you

must verify that the spacing between the bus bars meets minimum

requirements.

•

Apply final torque to all connections. Refer to the table below for torque

specifications.

Step 16: Install the AC Input

Cables

•

If necessary, secure the AC input power cables to terminals 1L1, 1L2 and

1L3, and 2L1, 2L2 and 2L3 with the existing bolts and washers and hex nut.

Step 17: Complete the

Circuit Tests

Forward and Reverse Biased Diode Tests for Major Power Components

A forward biased diode test checks the semiconductor junctions between the

terminals and measures the voltage drop across those junctions. To pass each

test, the meter must display a voltage near 0.5V. If the test finds a short, the

meter will display “.000.” If the test finds an open circuit or reversed polarity,

the meter will display “.0L” (zero load).

A reverse biased diode test should find an open circuit, and the meter should

display “.0L” (zero load).

ATTENTION: National Codes and standards (NEC, VDE, BSI

etc.) and local codes outline provisions for safely installing

electrical equipment. Installation must comply with

specifications regarding wire types, conductor sizes, branch

circuit protection and disconnect devices. Failure to do so may

result in personal injury and/or equipment damage.

Voltage

IEC Clearance

UL508 Clearance

400V

12.70 mm

0.5 in or 12.70 mm

480V

12.70 mm

0.5 in or 12.70 mm

600V

12.70 mm

0.5 in or 12.70 mm

690V

13.80 mm

0.5 in or 12.70 mm

Hardware

Torque

N•m

ft•lb

in•lb

M4

1.36

1.0

12.0

M8

11.3

8.3

100.0

M10

22.6

16.6

200.0

M12

39.5

29.1

350.0

ATTENTION: A hazard of personal injury and/or equipment

damage exists if the AC input power cable insulation becomes

damaged and/or fails. Precautions should be taken to ensure that the

insulation on the AC input power cables is not damaged during bus

bar installation and drive operation. Thoroughly inspect the cable

insulation to verify that no damage has occurred after the bus bar kit

has been installed.