O-ring removal – Rockwell Automation 2090-CPxxx Standard Power Cables with SpeedTec DIN Connector Type 923 User Manual

Page 5

Standard Power Cables with SpeedTec DIN Connector Type 923 5

Publication 2090-IN022A-EN-P - September 2010

2.

Keep cable bends within the bend radius specified on

.

Never bend a cable tighter than the specified bend radius. Refer to

for the

correct value.

3.

When installing the cable observe these restrictions:

•

The bend zone is the area where the cable can be bent to its specified bend radius.

•

The installation areas require strain relief to minimize cable flexing, and to reduce

the possibility of cable fatigue where the cable connects to other components.

4.

Identify each connection on a cable by attaching a label around the outer insulation of

each wire adjacent to the drive connection.

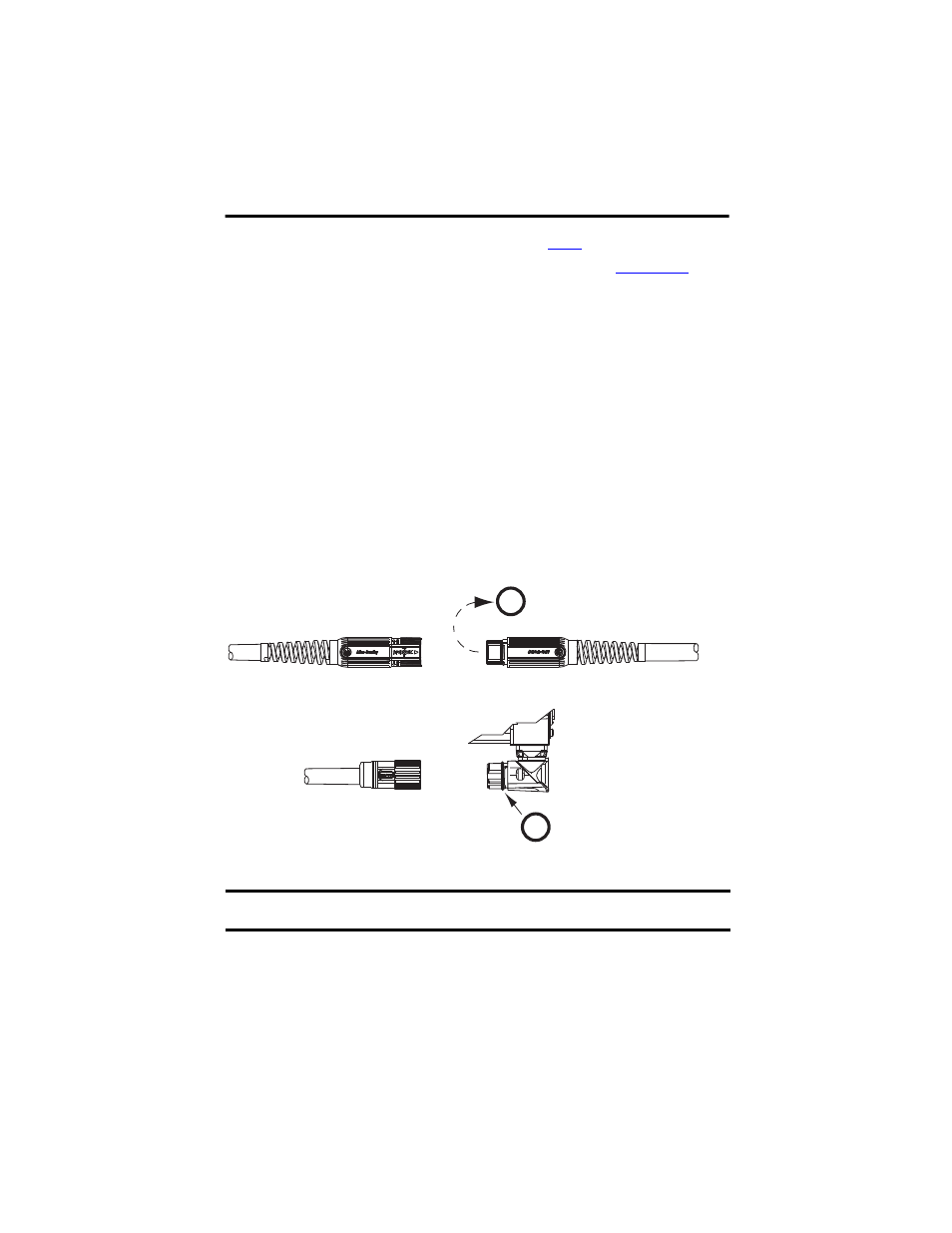

O-ring Removal

The type of plug on the connecting cable determines whether an O-ring is required on the motor

connector or the extension cable receptacle.

IMPORTANT

The O-ring dampens the effects of vibration at the connection.

This creates a more secure connection with the threaded plug.

SpeedTec Plug

Remove the O-ring from an

extension cable receptacle (shown) or

a motor connector that is SpeedTec ready.

With This Plug

Do This

Threaded Plug

For motors with a SpeedTec connector:

An O-ring may be installed on SpeedTec

ready motor connectors, and extension

cables.

Verify the O-ring is installed only when

mating with a threaded (non-SpeedTec)

plug.