Rockwell Automation 2100 CENTERLINE Bolted Pressure Contact Switch User Manual

Page 11

Publication 2100-IN049B-EN-P - February 2008

CENTERLINE

®

2100 Motor Control Centers 600A, 800A, and 1200A Bolted Pressure Contact Switch 11

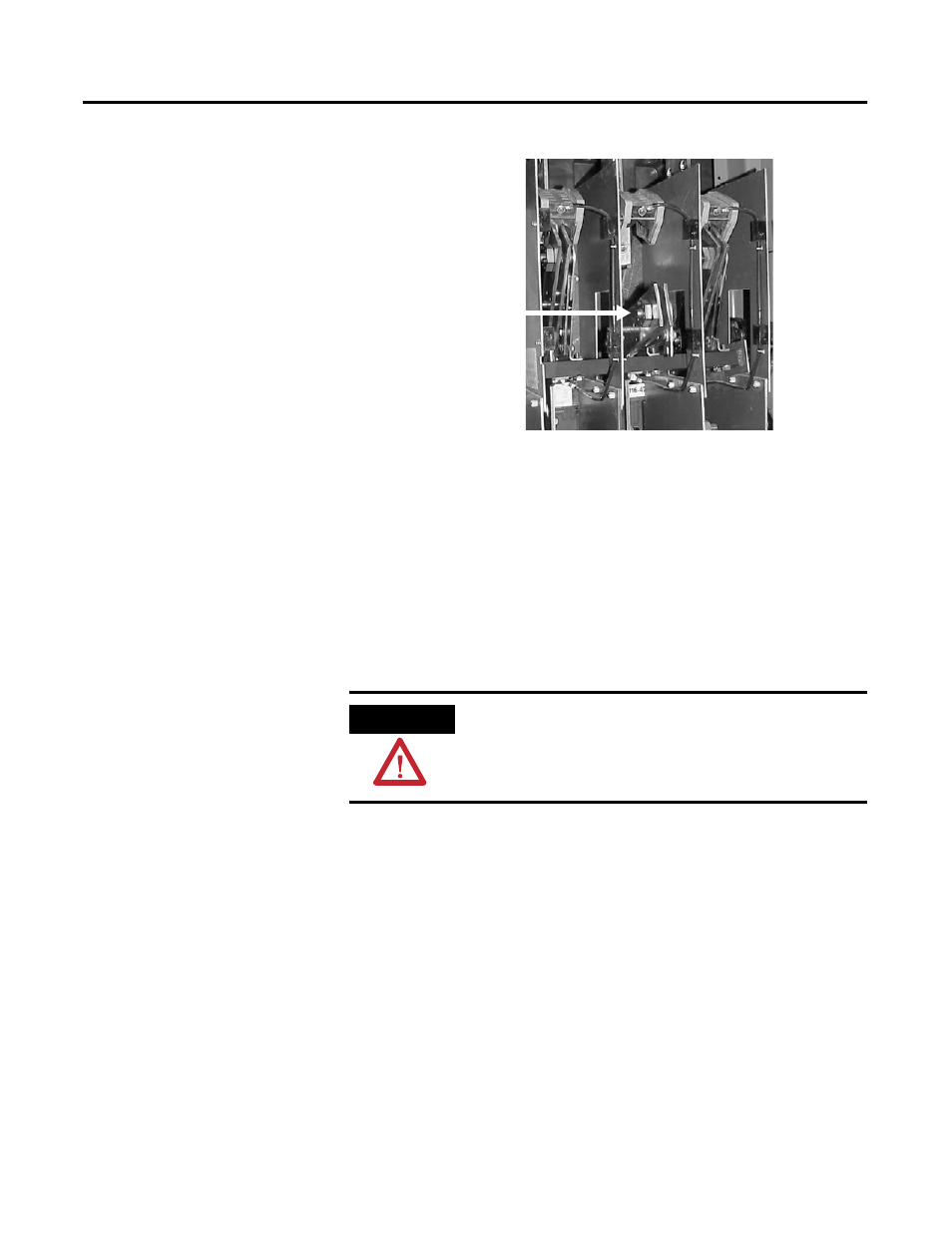

Figure 7 Contact (center pole), rotated for inspection and servicing

8. Generously apply the NO-OX-ID compound (enough to cover

with a noticeable film) to the cleaned inside movable contact

blades and the cleaned sides of the stationary contacts. Also

apply the compound to the hinge area (between the blades and

the stationary hinge). Work the compound into the hinge point

by rotating the contact blades several times. Do not loosen or

disassemble any of the large brass contact blade nuts. Do not

readjust these nuts or loosen the small Allen head set screw.

Refer to Figure 7.

9. Lubricate the BPS Linkages (they operate the bolts on the

Movable Blades) with light machine oil. Do not mix the light

machine oil with the previously applied NO-OX-ID compound.

Do not apply the light machine over the previously applied

NO-OX-ID compound.

10. Refer to Figure 6. Return the contact blades to their original

operating positions by rotating the contact blades (reverse the

procedure in step 6 of this section). An audible click will be

heard when the contacts have been returned to their original

positions.

11. Re-install the BPS clear cover with the eight cover screws that

were removed in step 5 of this section.

ATTENTION

The brass contact nuts are factory adjusted and must

not be loosened or tampered with. If the brass nut is

tampered with, the switch can malfunction and cause

these nuts to be out of adjustment.

Brass nut with

Allen screw