Rockwell Automation 9000 DeviceNet 9000 User Manual

Page 6

6

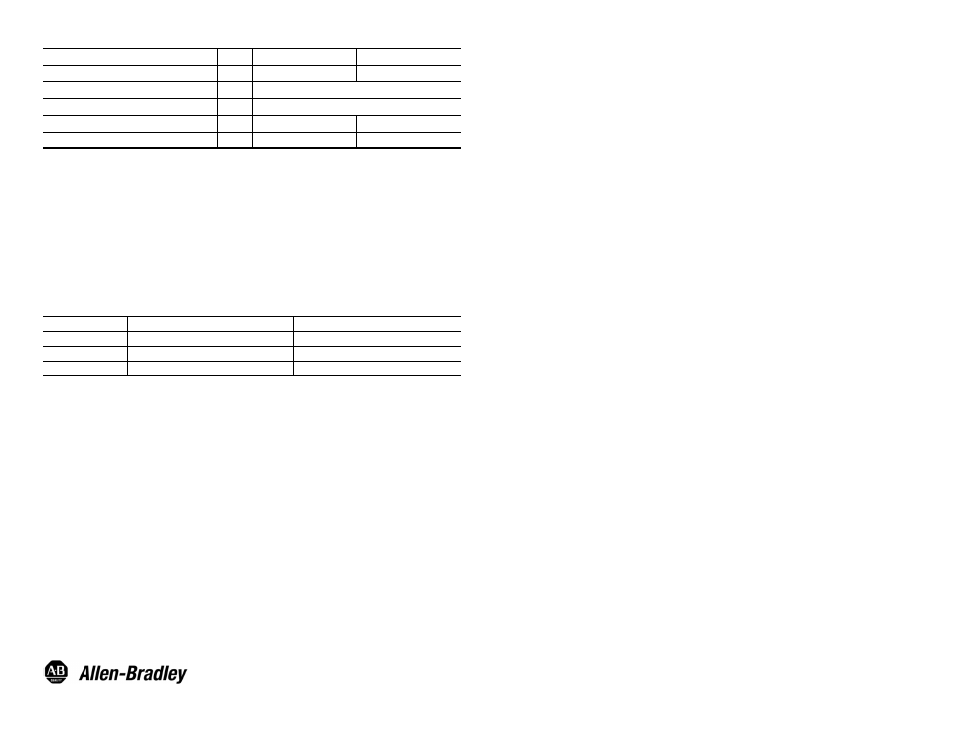

Table 2. Configuration Parameters

Parameter

Type

Options

Default

Operate Mode

R,W

Light or dark operate

Light operate

Sensor Output

R

Bit 0: 0=output OFF, 1=output ON

Diagnostic

R

Bit 1: 0=OK, 1=alarm

Communication Rate

R,W

125, 150, 300kB

125kb

Node Address

R,W

0 to 63

63

Diagnostic Operation

The Series 9000 DeviceNet sensors provide a diagnostic output bit to indicate an

unstable sensing condition. This condition can be caused by a “dirty or contaminated”

lens or by sensor misalignment. Strobing models of the sensor will output immediately

upon detection of a margin value between 1 and 2.5. This method, called static

diagnostic, is ideal for web sensing applications where an immediate indication is

required. The diagnostic bit of COS models will not output until a complete “low margin”

transition occurs. Called dynamic diagnostics, this method is best suited for

applications where targets are constantly moving into and out of the sensor field of

view, i.e., conveyor application.

Data Byte 1

Bit 0

Bit 1

Output

Diagnostic

0

OFF

OK

1

ON

ALARM

Transmitted Beam Mode

Visually align the emitter and receiver units (emitter and receiver fibers) until the Output

LED on the top of the control lights up (with Light Operate mode) or goes out (with Dark

Operate mode).

To be certain that the beam is centered, it is required to sweep the emitter or receiver in

the horizontal and vertical plane and determine at what position the output indicator

goes on and then goes off. Set the sensor (or fiber optics) halfway between both

positions. The Margin LED should also be on when the beam is unbroken.

Retroreflective/Polarized Retroreflective Mode

Visually align the sensor (or fiber optic cable) on the reflector until the Output LED on

the top of the control lights up (with Light Operate mode) or goes out (with Dark

Operate mode). Also verify that the Margin LED is on.

To be certain that the beam is centered, it is required to sweep the sensor in the

horizontal and vertical plane and determine at what position the output indicator goes

on and then goes off. Set the sensor (or fiber optics) halfway between both positions.

Break the beam with the object to be detected and check if the output indicator turns

on. When this does not happen turn down the sensitivity adjustment until it does.

Restore the light beam by removing the object and check if the output indicator turns off

again and that the Margin LED comes on. If this does not happen, increase the size of

the reflector or decrease the distance between the reflector and the sensor.

Diffuse Mode

Visually align the sensor (or fiber optic cable) on the object until the Output LED on the

top of the control lights up (with Light Operate mode) or goes out (Dark Operate mode).

To be certain that the beam is centered, it is required to sweep the sensor in the

horizontal and vertical plane and determine at what position the output indicator goes

on and then goes off. Set the sensor (or fiber optics) halfway between both positions.

Remove the object in front of the sensor and eliminate any background signals by

turning down the sensitivity adjustment, if such background signals exist. Replace the

object and verify that the output LED goes on and that the Margin LED is on.

Publication 75025--381--01(A)

May 2001

Printed in USA

PHOTOSWITCH

R

is a registered trademark of Rockwell Automation/Allen-Bradley.