Rockwell Automation 7000 PowerFlex Medium Voltage Air-Cooled (B Frame) Installation - ForGe Control User Manual

Page 75

Rockwell Automation Publication 7000-IN007E-EN-P - June 2014

75

General Reference

Appendix A

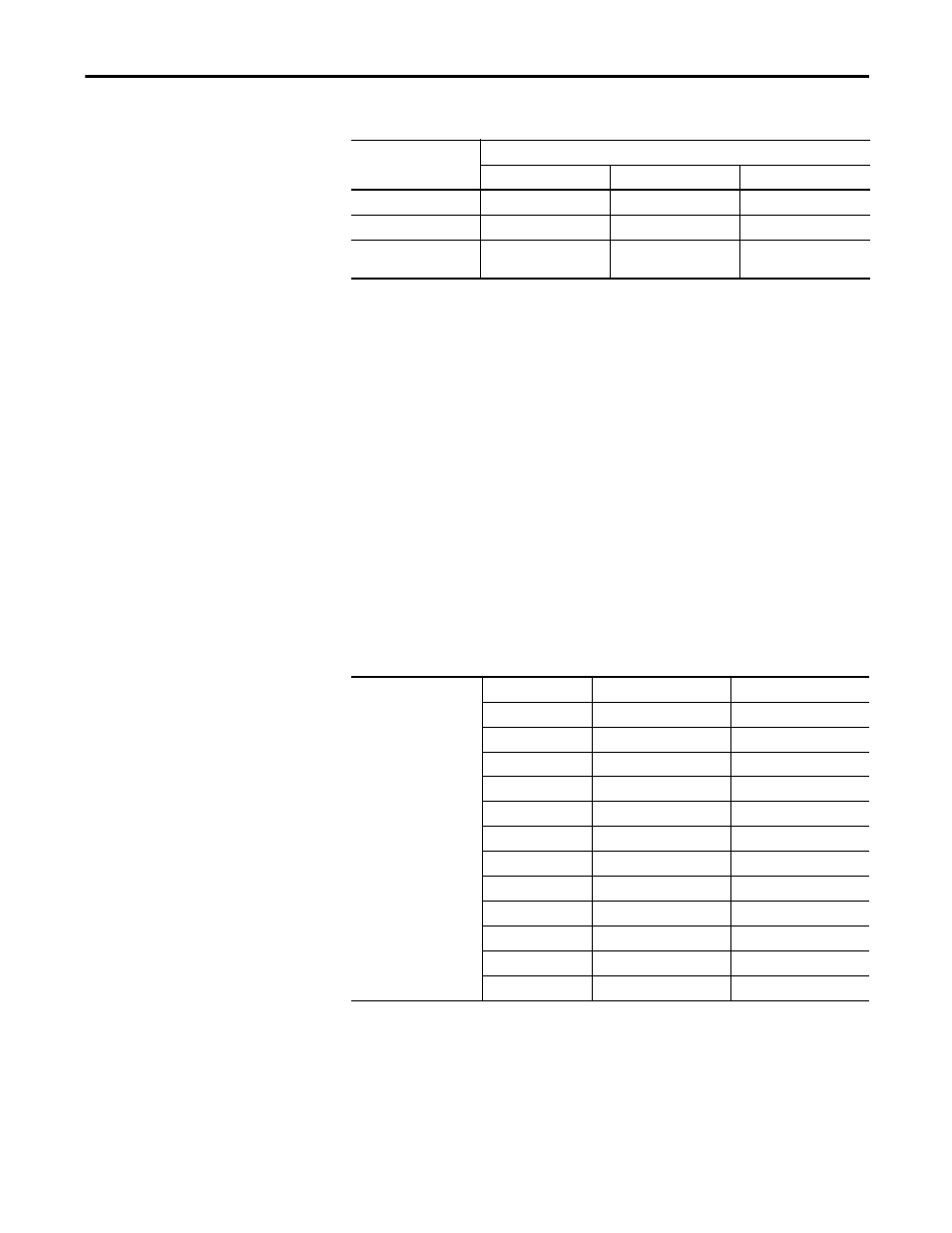

Table 11 - PowerFlex Speed Regulation

Notes:

•

Speed regulation is based on a percentage of motor synchronous speed.

•

Encoder to be mounted on the AC machine

•

Operational 15V DC Power Supply mounted in drive to power the

encoder as a standard option with the encoder feed back card.

•

Customer is responsible for providing and mounting of encoder

•

Sleeve bearing motors require the encoder to have an axial movement

tolerance.

•

Recommended encoders are shaft mounting type.

•

Magneto resistive models are more adaptable to harsh environments.

•

When installing, the encoder body and electronics must be isolated from

ground (options available from the encoder manufacturer to accomplish

this).

•

There are usually limits on encoder cable lengths. Ensure the maximum

length is suitable for the application.

Encoder

Frequency Output

<6 Hz

6...15 Hz

>15 Hz

Without Encoder

Not applicable

0.1%

0.1%

With Encoder

0.02%

0.01%

0.01%

With Encoder and HPTC

mode enabled

0.01%

0.01%

0.01%

Table 12 - Encoder Selection

High Performance

Torque Control (HPTC)

Mode

Motor RPM

Minimum Tach PPR

Recommended Tach PPR

3600

1024

1024

3000

1024

1024

1800

1024

2048

1500

1024

2048

1200

2048

2048

1000

2048

2048

900

2048

4096

720

4096

4096

600

4096

4096

450

4096

8192

360

8192

8192

300

8192

8192