Cable installation guidelines – Rockwell Automation 2090-CPBM7DF-16RAxx SpeedTec Right-angle Standard Power and Feedback Cables User Manual

Page 4

4 SpeedTec Right-angle Standard Power and Feedback Cables

Publication 2090-IN045A-EN-P - August 2012

Cable Installation Guidelines

Follow these guidelines when installing a cable.

1. Identify the recommended installation areas and the correct offset from features before

beginning any cable bend.

Features include these areas on the cable:

•

Connectors

•

Transitions from exposed wire to insulation (for example, flying leads)

•

Exposed cable ground shields

The offset from these features should be greater than or equal to (

≥1x) the cable

diameter.

2. Keep cable bends within the bend radius specified on

3. Observe these restrictions when installing the cable:

•

The bend zone is the area in which the cable can be bent to its specified bend radius.

•

The installation areas require strain relief to minimize cable flexing, and to reduce

the possibility of cable fatigue where the cable connects to other components.

I

4. Observe these restrictions when attaching a cable connector to the motor connector:

a. Align all flat surfaces on the cable connector with the flat surface on the motor

connector.

b. Push the cable connector onto the motor connector to fully seat the connection.

c. Twist the knurled front-end of the cable connector approximately 60° to the right to

secure the connection.

TIP

You may identify each connection on a cable by attaching a label around the outer insulation of

the wire adjacent to the connection.

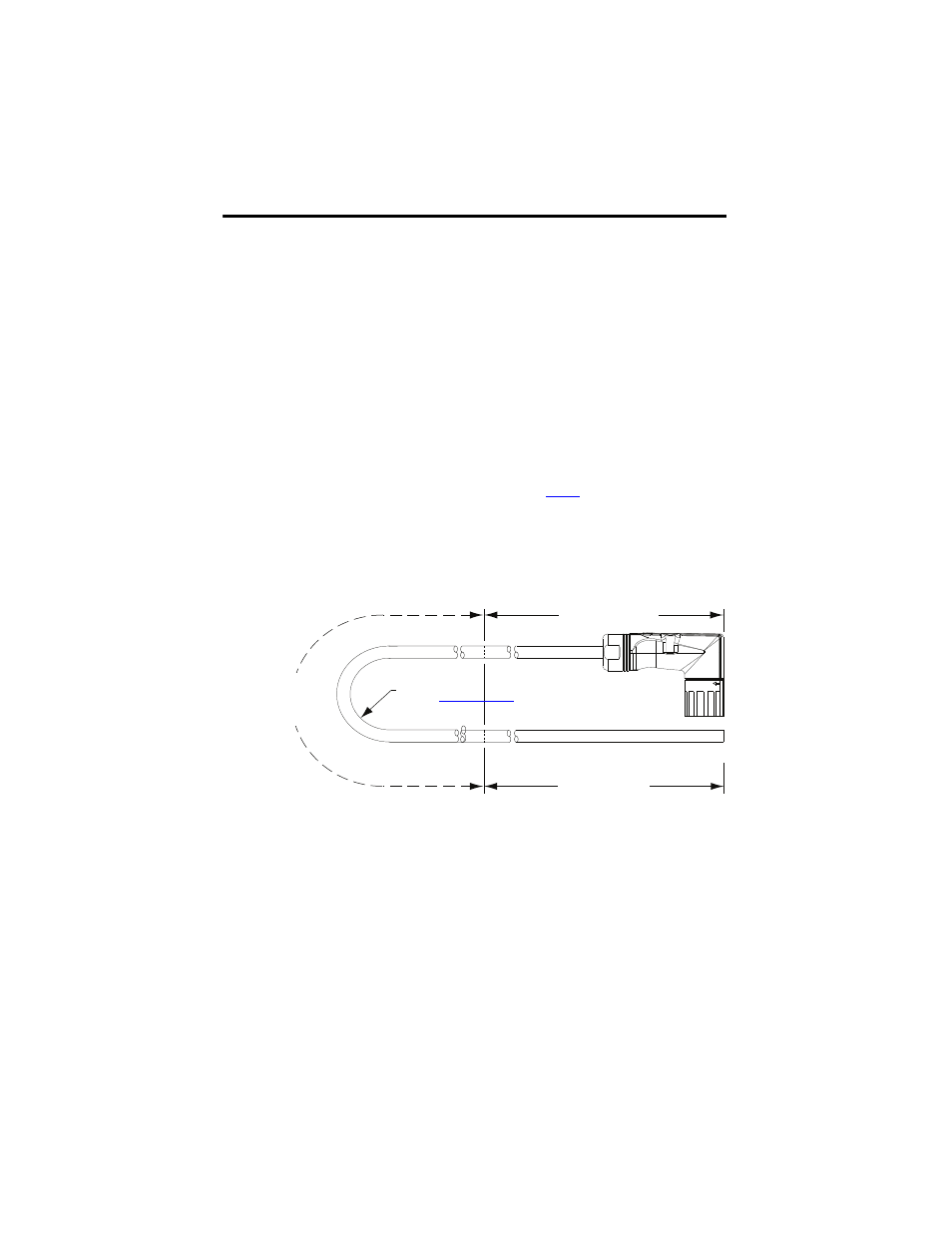

Bend Zone

Flex Restrictions Apply

2090-CFBM7DF-CERA

xx shown

Installation Area

300 mm (12 in.) approx.

Bend Radius

Refer to

for value.

Installation Area

300 mm (12 in.) approx.