Torque specifications and table, E torque requirements on, Torque specifications and – Rockwell Automation 2100 CENTERLINE MCC Joining Splicing Vertical Sections User Manual

Page 15: Table

CENTERLINE

®

2100 Motor Control Centers Joining and Splicing Vertical Sections

15

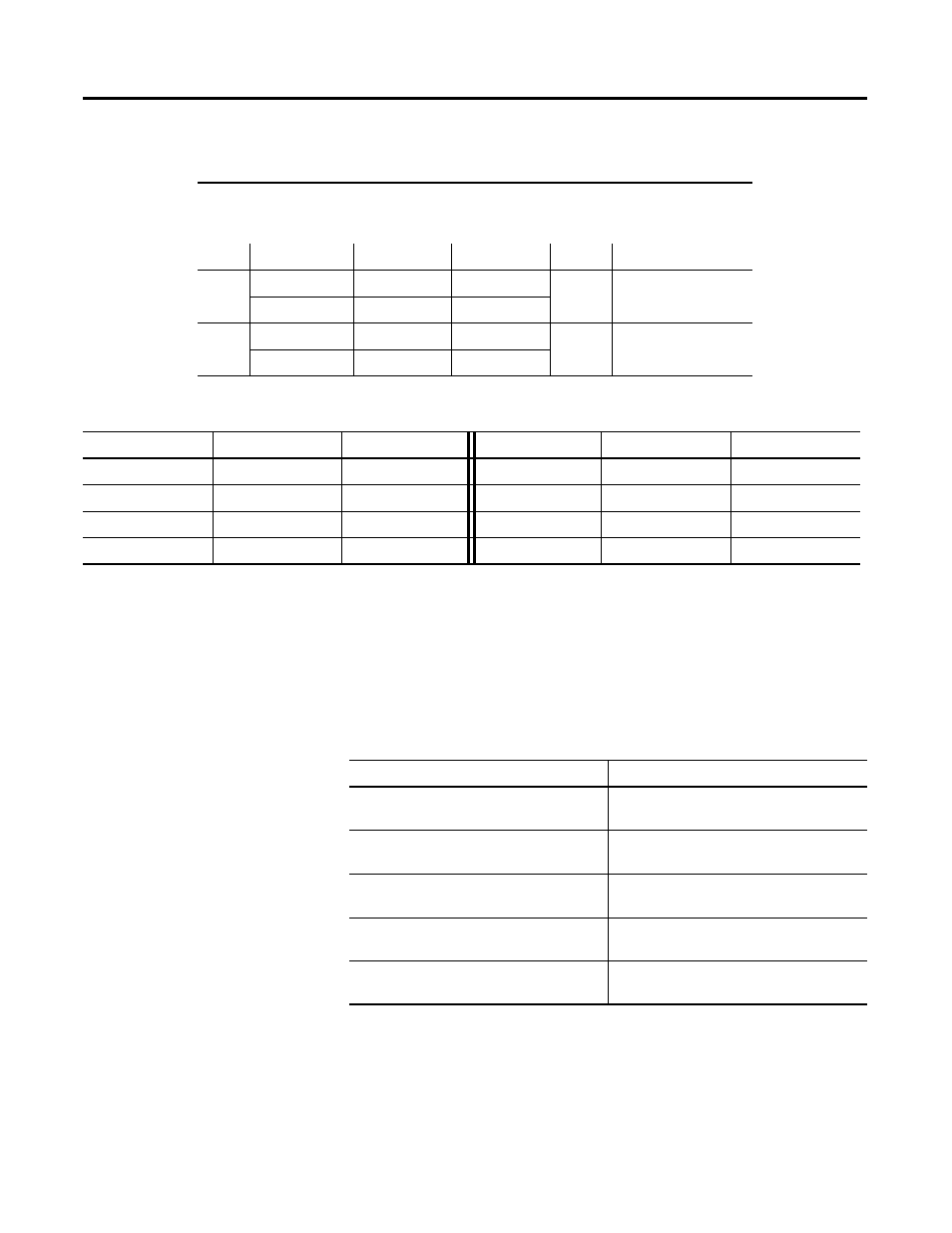

“Z” SPLICE BAR

(Used to Splice Standard Depth Bus to Bus 5” Deeper)

Note: 600-1200 AMP Bus is the same thickness as a standard Splice Bar

AMP

MATERIAL

QTY

THICKNESS

WIDTH SPLICE MTG. HOLES

1600

Copper/Tin

1

.500”

4”

4

Copper/Silver

1

.500”

2000

Copper/Tin

1

.625”

4”

4

Copper/Silver

1

.625”

Table B Conversions

DECIMAL

FRACTION

MILLIMETER

DECIMAL

FRACTION

MILLIMETER

.125”

1/8”

3.175

.375”

3/8”

9.525

.250

1/4”

6.350

.625”

5/8”

15.875

.500”

1/2”

12.700

3”

3”

76.200

.1875”

3/16”

4.763

4”

4”

101.600

Torque Specifications and

Tighten all bus connections with a torque wrench and socket according to

intervals established by your maintenance policy. If a torque wrench is not

Table

available, tighten until conical spring washer is flat. Do not grease or lubricate

the hardware.

Table C Torque Requirements

Description

Lug attachment bolts

1/2-13 Hardware

Horizontal to vertical bus connection

3/8-16 Hardware

Horizontal splice connection

3/8-16 Hardware

Connecting Hardware

1/4-20 Hardware

10-32 Hardware

Torque in Ft./Lb.

45 lb.-ft. ± 5 lb.-ft.

61 N-m ± 6 N-m

28 lb.-ft. ± 4 lb.-ft.

38 N-m ± 5 N-m

28 lb.-ft. ± 4lb.-ft.

38 N-m ± 5 N-m

55 lb.-in. ± 3lb.-in.

6.2 N-m ± 0.6 N-m

32 lb.-in. ± 3lb.-in.

3.6 N-m ± 0.4 N-m

Publication

2100-IN010D-EN-P—February 2007