Rockwell Automation 2100 CENTERLINE MCC Joining Splicing Vertical Sections User Manual

Page 11

CENTERLINE

®

2100 Motor Control Centers Joining and Splicing Vertical Sections 11

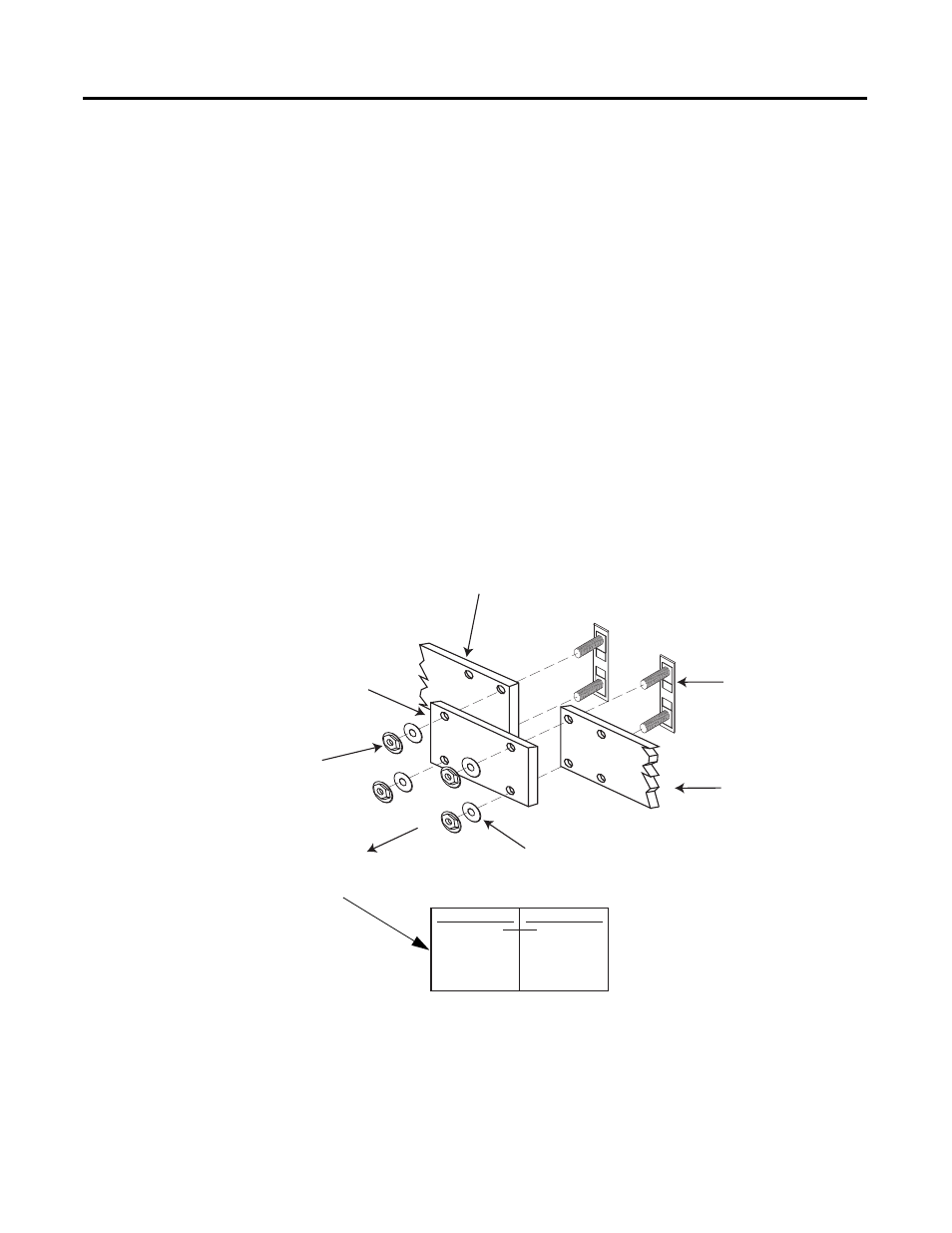

2. Assemble splice bars to the bus work of the vertical sections as shown in

figure 8 - 13. If additional access to the splice is desired, loosen the

fastening screws and remove the bus access plate located in the vertical

wireway of the center (to the left of the splice). The horizontal bus now

is exposed to the left and right of the splice for added convenience. The

splicing kit will contain either two or four sets of hardware per splice

bar, depending on the current rating of the horizontal bus.

3. See Table A on page -14 for bus dimensions and mounting holes.

4. Tighten to torque specifications as listed in the Torque Requirements on

page -15 or tighten until the conical spring washer is flattened on the

one-piece nut and washer assembly. Do not grease or lubricate the

hardware.

5. Replace covers and plates and check all bolts and nuts for tightness.

Replace units in their respective stations.

Figure 8 600 - 1200 Amp Main Horizontal (and Neutral) Bus Splicing Detail and

Configuration Example

Main Horizontal Bus

or Neutral Bus

One-piece assembly of

nut and conical spring

washer

Two Hole Main

Horizontal Splice

Front

Flat Washers

Main Horizontal Bus

or Neutral Bus

Bus Clamps

Splice Kit Configuration Example (Top View - 2 Sections)

Refer to Table A for bus size and thickness.

Publication

2100-IN010D-EN-P—February 2007