Rockwell Automation 1771-IR Series D RTD Input Module User Manual User Manual

Page 19

2–5

Installing the RTD Input Module

Publication 1771Ć6.5.129 - March 2000

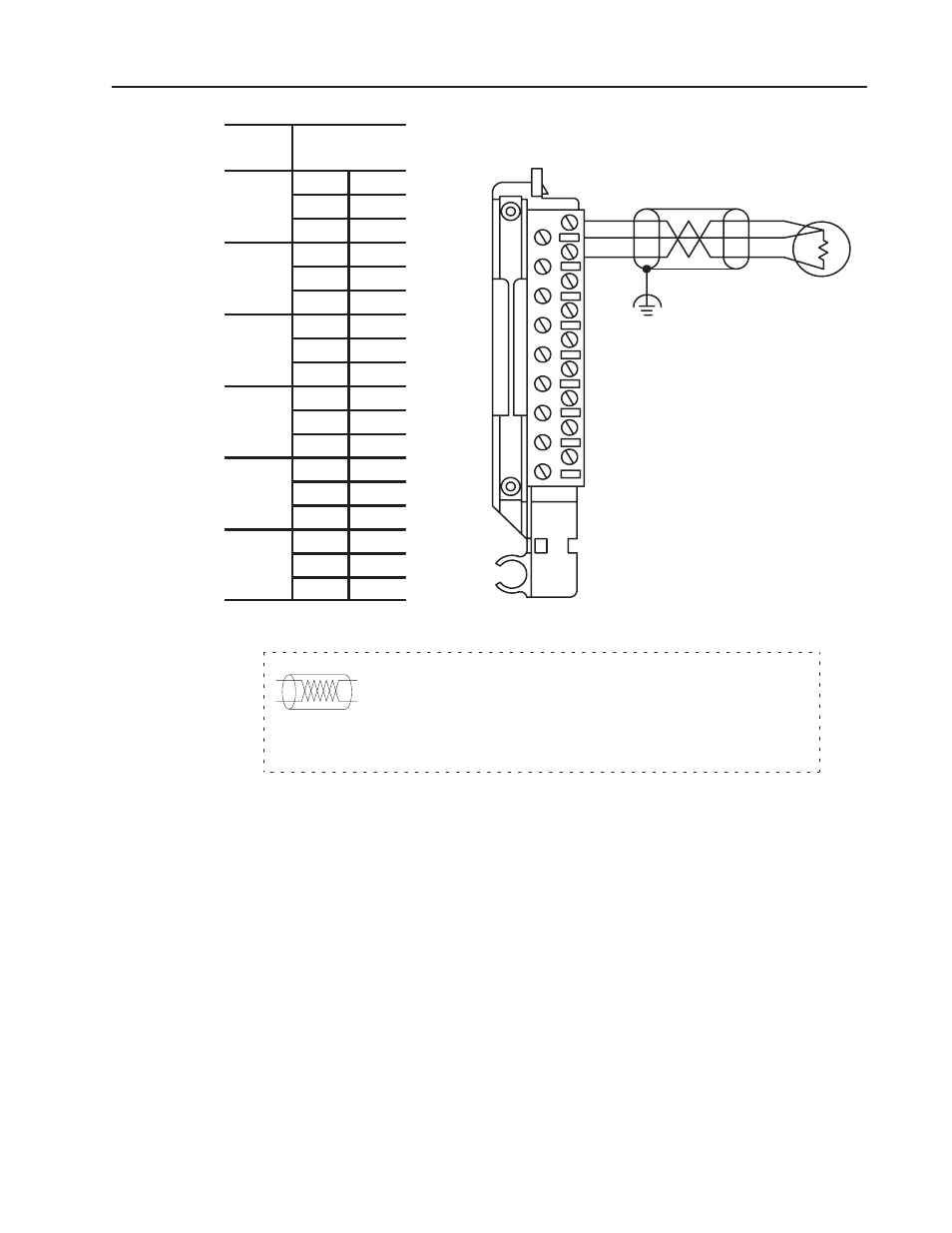

Channel

Terminal

Identification

1

18

C

17

B

16

A

2

15

C

14

B

13

A

3

12

C

11

B

10

A

4

9

C

8

B

7

A

5

6

C

5

B

4

A

6

3

C

2

B

1

A

Cable impedance –– Since the operating principle of the RTD

module is based on the measurement of resistance, you must take

special care in selecting your input cables. Select a cable that has a

consistent impedance throughout its entire length. We recommend

Belden 9533 or equivalent. As cable length is directly related to

overall cable impedance, keep input cables as short as possible by

locating your I/O chassis as near the RTD sensors as I/O module

considerations permit. Keep the cable free of kinks and nicks to the

shielding material.

Connection Diagram for the RTD Input Module (1771ĆIR/D)

Field Wiring Arm

Cat. No. 1771ĆWF

18

17

16

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

11846ĆI

RTD

(Channel 1 shown)

Functional

Ground

The sensor cable must be shielded. The shield must:

•

extend the length of the cable, but be connected only at the 1771 I/O chassis

•

extend up to the point of termination

Important:

The shield should extend to the termination point, exposing just enough cable to

adequately terminate the inner conductors. Use heat shrink or another suitable

insulation where the wire exits the cable jacket.

Refer to Appendix E for 2-wire and

3-wire RTD connections.