1397-db-b400l-b600l, Verify that the jumper between terminals 3 – Rockwell Automation 1397 Open Chassis Dynamic Brake User Manual

Page 9

1397 Open Chassis Dynamic Brake

9

1397-5.15 March, 1999

181/L1

81

47 (+)

45 (–)

M

M

A1

M

ARMATURE

SUPPLY

1397 DRIVE

DB RESISTORS

282

281

283

AC

INPUT

82

83

182/L2

182/L3

A1

A2

MOTOR ARMATURE

2

DBR

A2/S1

1

1

1FU

2FU

3FU

3

2 4 F1 F2

1

P6-5 P6-2

RRB1-5

RRB1-6

35-F2

37-F1

DBCR

13

FROM

FIELD

SUPPLY

14

M AUX

DYNAMIC BRAKE

TERMINAL BLOCK

MOTOR SHUNT FIELD

3

S2

1397-DB- B400L — B600L

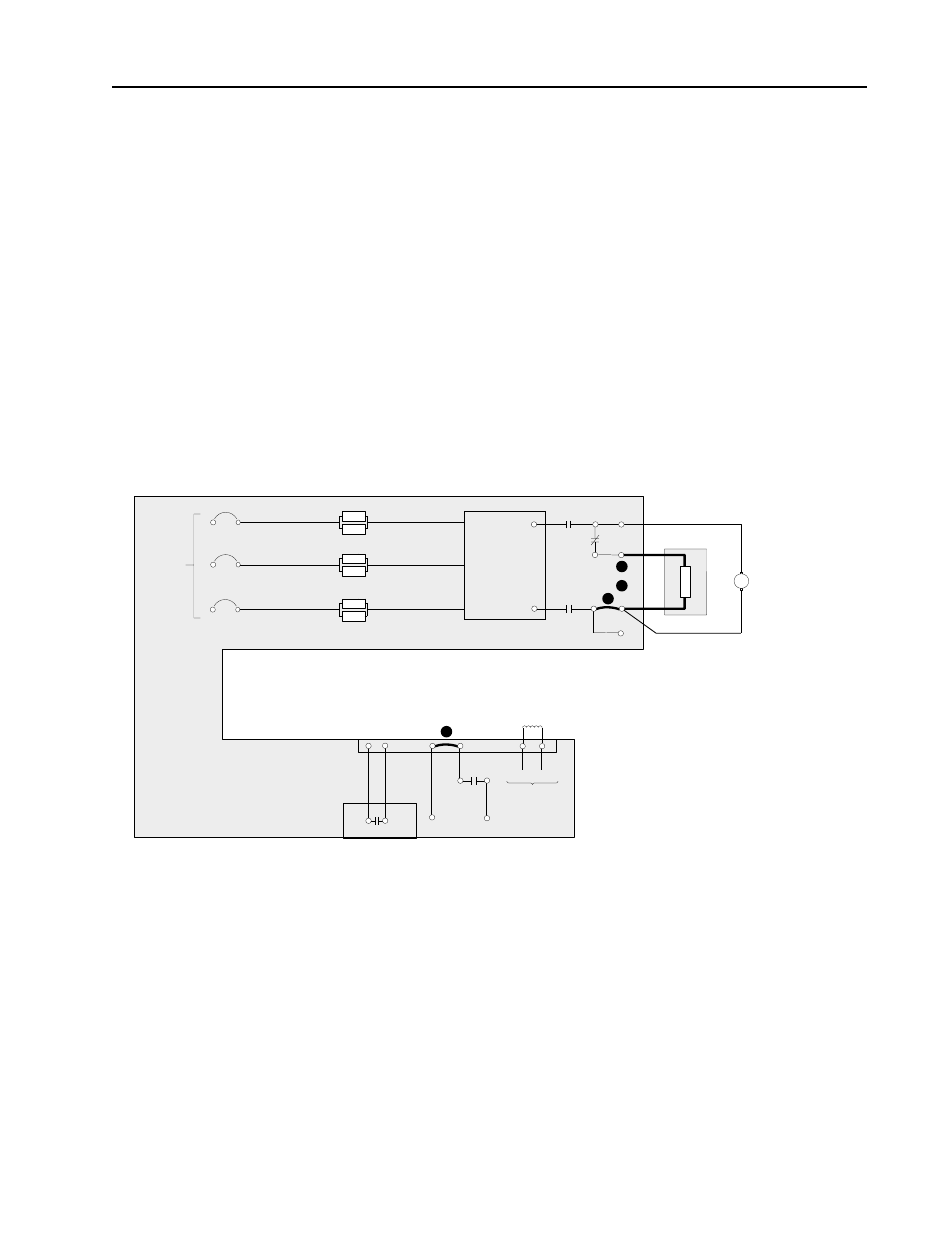

Dynamic Brake Kit Operation

Dynamic braking slows down a rotating DC motor and its load. It is an uncontrolled process. During dynamic

braking, the motor armature is disconnected from the drive. A resistor is placed across the motor’s rotating

armature (now acting as a generator), and the resulting current causes braking torque in the motor. The motor

will decelerate, even with a drive malfunction, as long as motor shunt field excitation is maintained.

When the motor is running normally, the drive’s normally-open M contacts are closed and the normally-closed

M contact is open. When the drive is connected to the motor, the dynamic braking resistor assembly is

disconnected.

For 1397-DB-B400L — B600L Kits

If You are Using the Basic Configuration . . .

Remove and lockout all power to the drive and follow the wiring diagram above.

➊

Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

&

A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

➋

Verify that the removable connector bar link at A2/S1 is installed.

➌

Verify that the jumper between terminals 3

&

4 at the drive terminal block is installed.

Remove the lockout and reapply power. Refer to

1397-DB-B400L — B600L Dynamic Brake Kit

Operation

above and proceed to

Setup

on the last page.