Specifications and dimensions, Chapter – Rockwell Automation 1608P ProDySC Installation Instructions, 25 and 50 A User Manual

Page 19

Rockwell Automation Publication 1608P-IN001B-EN-P - May 2014

19

Chapter

5

Specifications and Dimensions

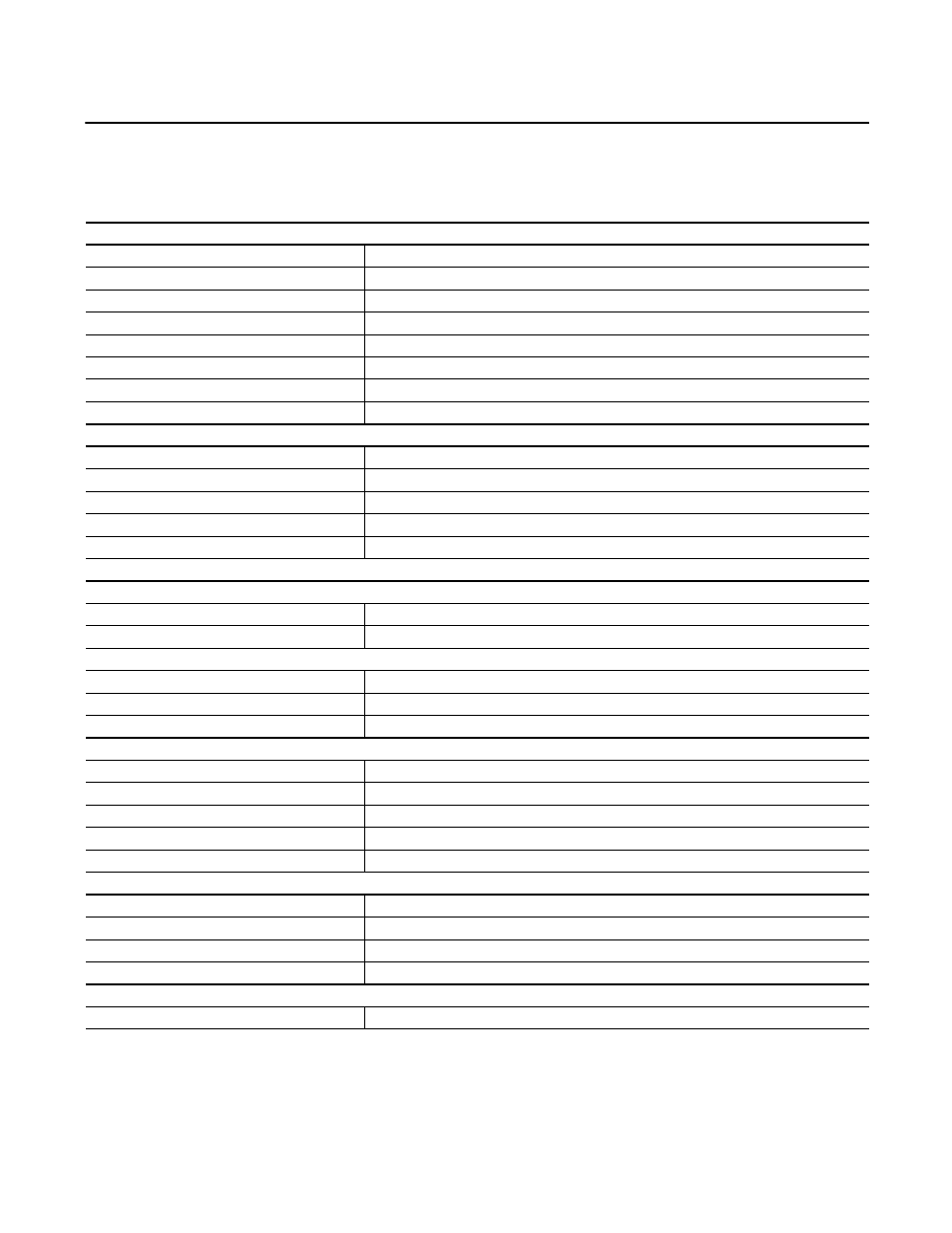

Table 4 - Technical Specifications

Electrical Input/Output (Normal Mode—Static Switch)

Connection Configuration

Series-connected with load. Under normal line condition, the static switch passes utility voltage directly to the load

Standard Input Voltages

3

: 208, 380, 400, 415, 480V

1

Voltage Range

± 10%

Current Overload (Static Switch)

150% @ 30Sec., 400% @ 5 Sec., 600% @ 0.5 Sec.

Frequency

50/60 Hz Auto Sensing

Frequency Range (tracking)

45 to 65 Hz

TVSS

Built-in 3-Layers consisting of MOVs & Capacitors

Efficiency

> 99% @ 480V

Electrical Output (Sag Correction Mode - Inverter)

Output Voltage

Pre-sag rms voltage

Voltage Regulation

+5%-13% of nominal

Output Current

2

Rated RMS (25A or 50A). Not rated for DC loads: max. allowable 2% DC loading

Crest Factor (at nameplate rms load)

1.45

Voltage Waveform

Sine wave

Voltage Sag Correction Times

Single Event

3 phase 87% to 50% Voltage Remaining

5 seconds

All three phases to zero voltage remaining

50ms or 200ms (SR or ER). Based on load at nameplate ratings with a power factor of 0.7

Multiple Event

Max Sag Correction Time

5 seconds cumulative usage

Sequential Sag Recovery

0 seconds (assuming cumulative run-time available)

Full Recovery Time

Max 5 minutes

Mechanical

Enclosure Ratings

NEMA 1 (IP20)

Cable Entry

Top

Cooling

Filtered Forced Air

Access

Front for servicing and connections

Bypass (External)

Panel mounted for PM or servicing ProDySC

Environmental

Ambient Temperature

0 to 40°C

Storage Temperature

-40°C to 75°C

Relative Humidity

0 to 95% non-condensing

Altitude

Rated current available to 1000m (3300ft). De-rate output current 10% per 1000m, from 1000m to 3000m (9900ft).

Safety

Agency Approvals

cULus Listed

1. ProDySC has not been evaluated for use in Corner Grounded or Ungrounded Delta Power Systems

2. When using ProDySC with motor drive loads, either insert 3% to 5% line reactance at ProDySC output or limit motor drive loads to 60% of ProDySC rating