Calibration, Specifications – Rockwell Automation 1414-IPZxxxxx_CPZxxxxx_CPDxxxxx Differential Air Pressure Transmitter User Manual

Page 9

Differential Air-pressure Transmitter 9

Publication 1414-IN011B-EN-P - July 2010

Calibration

All pressure ranges are factory calibrated and no calibration is necessary. You may adjust the zero

point if desired when changing ranges for example.

1. Allow the product to warm-up for 10 minutes (one hour is best) before you make a zero

adjustment.

2. With both ports open to the ambient pressure, press and hold the auto-zero button for at

least three seconds.

3. Release the auto-zero button after at least three seconds and the device will calculate and

store the new zero point.

Specifications

TIP

Generally, we do not recommended that the span calibration be performed in

the field unless a high quality calibrator with low differential pressure ranges is

available and the temperature of the sensor can be maintained. Contact the

factory for information on this type of calibration.

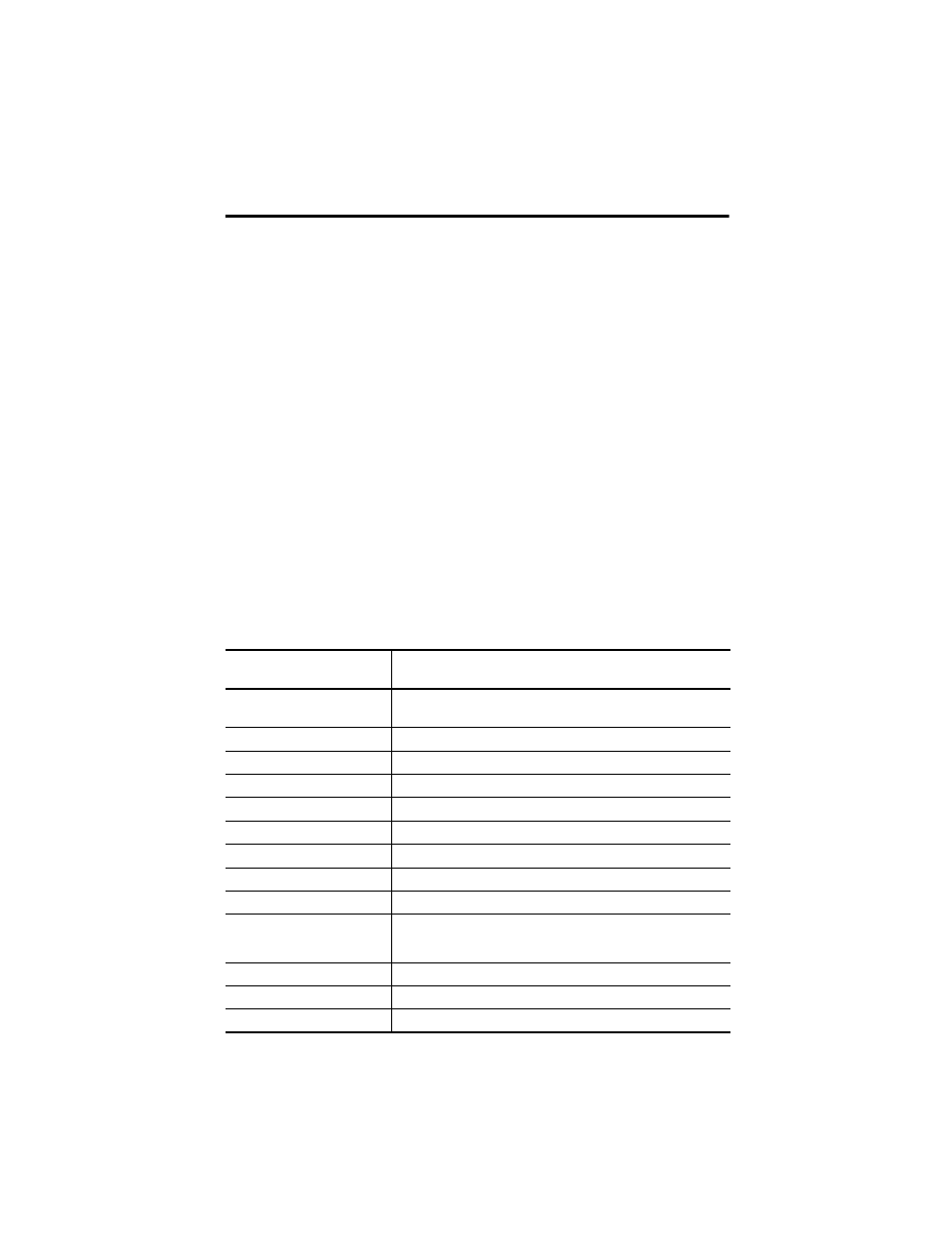

Technical Specifications - Differential Air-pressure Transmitter

Attribute

1414-IPZ10FODAA, 1414-IPZ10FNDAA, 1414-IPD10FNRAA,

1414-CPZ10FODAA, 1414-CPZ10FNDAA, 1414-CPD10PNRAA

Pressure ranges

±0.5 in., ±1 in., ±2 in., 0…1 in., 0…2 in., 0…4 in. wc

±1.5 in., ±3 in., ±6 in., 0…3 in., 0…6 in., 0…12 in. wc

Calibration accuracy

± 1% F.S.O.

Measurement type

Differential (two port)

Response time

1 mS maximum

Stability

< ± 1% F.S.O. per year

Thermal effects

< ± 3% over compensated range

Compensated range

10…50 °C (50…122 °F)

Over pressure

20 psi or 2 x range (whichever is greater)

Operating conditions

0…60 °C (32…140 °F), 10…90% RH non-condensing

Media compatibility

Limited only to those that will not attack polyetherimide, silicon,

fluorosilicone, silicone, EPDM, and neoprene seals. Typically dry air or

inert gas but liquid is allowed.

Power supply (at transmitter)

12…28V AC, 15…35V DC (non-isolated half-wave rectified)

Supply current

< 4 mA

Input voltage effect

Negligible over specified operating range