Installation – Rockwell Automation 1397 400-600HP AC Line Disconnect Inst. User Manual

Page 4

1397 600HP AC Line Disconnect

4

1397-5.30 July, 1998

BLOWER MOTOR

STARTER KITS

283

5FU

4FU

282

281

288

289

ON

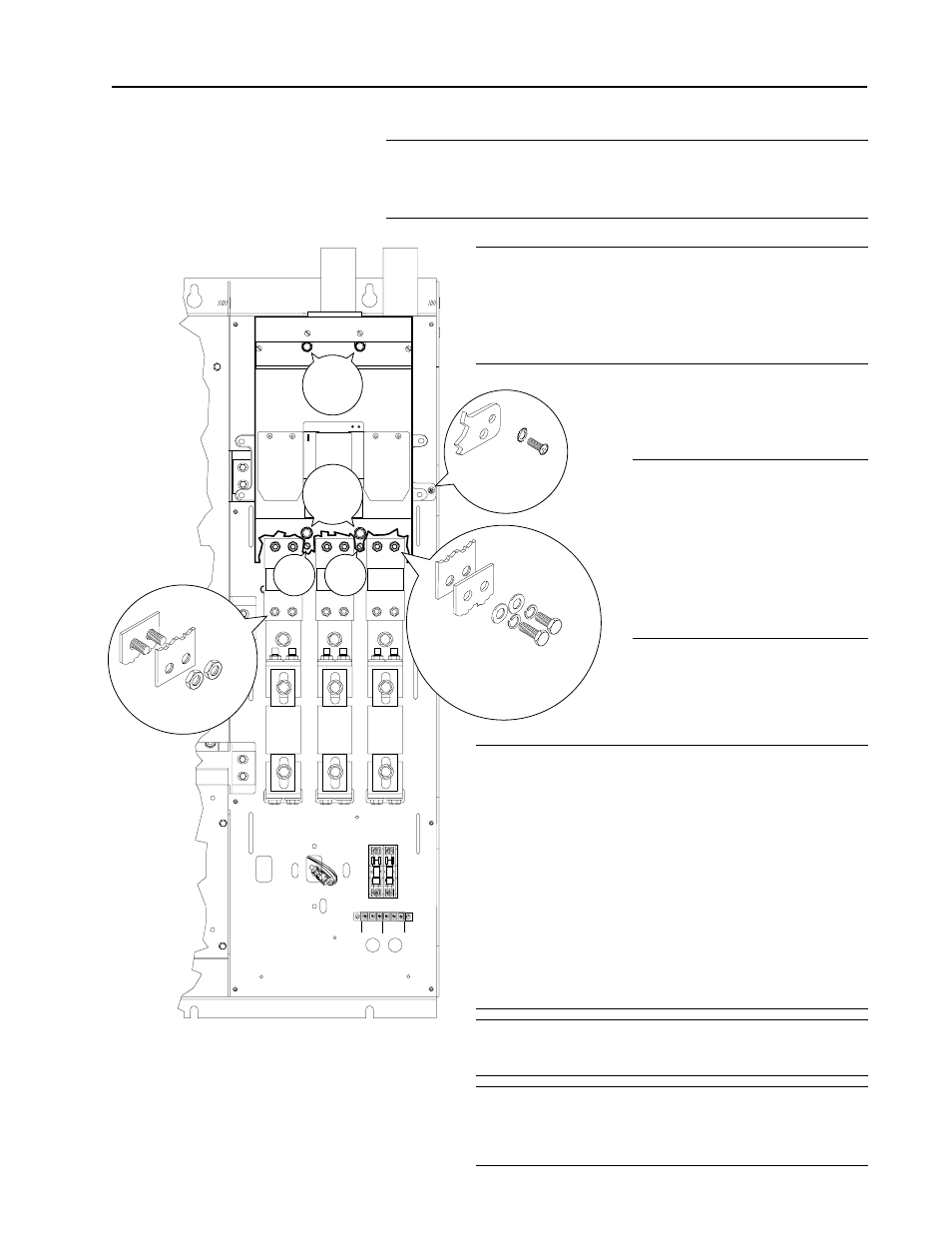

M8 Bolt

and Lock-

washer

M8 Bolt

and Lock-

washer

Cover

Screw

Cover

Screw

7/16" Flat Washer

7/16" Split Lockwasher

7/16" x 1" Bolt

— (6) Places —

Bus Bar

(top)

M12 Nuts

— (6) Places —

Bus Bar

(bottom)

Adapter

M5

×

20

mm Screw

and M5 Toothed

Lockwasher

Installation

❐

9

While holding the spacer and adapter plate in place, pick up the

disconnect and position it over the threaded holes on the drive’s

mounting panel.

❐

11

Install the M5

×

20mm

phillips head screw and M5

toothed lockwasher where

the screw was removed in

Step 4

. Torque to 2.8 N-m

(25 lb-in.). This establishes

a ground connection for the

disconnect switch.

❐

13

Replace the disconnect’s bottom lug cover and

tighten the (2) captive screws to secure it in place.

❐

14

Replace the plastic line fuse cover removed in

Step

1

and tighten the (2) screws at the bottom to secure

it in place.

❐

12

Remove the disconnect’s lower lug cover by

loosening the (2) captive cover screws. Attach a bus

bar between the drive’s right-side line fuse

connector and the disconnect’s right-side load

connector. Use (2) 7/16" flat washers, (2) split

lockwashers

&

(2) 1" bolts for the disconnect

connection. Use two of the M12 nuts removed in

Step 3

for the line fuse connection. Repeat this

procedure to attach the remaining bus bars. Tighten

the bus bar to disconnect bolts to 34N-m

(300lb.-in.). Tighten the bus bar to line fuse

terminal nuts to 24 Nm (210 in-lb).

❐

10

Attach the disconnect by hand tightening the (2) bolts

inserted previously. After the bolt threads catch in

the bolt holes, insert the remaining (2) mounting

bolts

&

lockwashers. Tighten all bolts to 14N-m

(125lb.-in.).