Rockwell Automation 875 Capacitive Proximity Sensor User Manual

Page 3

Target Considerations

Standard Target

The standard target is a grounded, 1mm-thick square of mild

steel. The side lengths of a standard target are equal to either

the diameter/width of the sensor face or three times the

nominal sensing distance, whichever is greater.

Shielded vs. Unshielded

Shielded capacitive sensors can be used to sense either

conductive (metal, water) or nonconductive (wood, paper,

glass, plastic) materials. Their internal ground allows them to

detect grounded or ungrounded targets. It also makes them

more susceptible to dust and moisture in the environment than

unshielded sensors.

Unshielded capacitive sensors are used primarily to sense

grounded, conductive materials at maximum sensing

distances. They are less sensitive to nonconductive materials

than shielded sensors. This makes them able to detect

conductive materials through a nonconductive material, such

as water inside a plastic tank. In this case, the nonconductive

material can be no thicker than the sensor’s sensing distance.

(Note: capacitive sensors cannot sense through metals.) Dust

and moisture in the atmosphere have less effect on

unshielded sensors than on shielded models.

Grounding

Targets should be grounded for most reliable sensing. If a

ground path to the target is not available, shielded sensors are

recommended. When attempting to detect nonconductive

materials with an unshielded sensor, a path to ground is

required.

Dielectric Constants

The dielectric constant is one of the material properties of a

target. Materials with higher dielectric constants are more

easily detected by capacitive sensors and are therefore

detected at greater sensing distances than those with low

constants. See page 4 for a list of common industrial materials

and their dielectric constants.

Correction Factors

Correction factors are multipliers which are determined by a

target’s mass, material, and grounding state. To calculate an

approximate sensing distance for an application, multiply the

nominal sensing distance S

n

by the correction factor for that

application’s target. The table below shows some typical

correction factors.

Correction Factors for Common Materials

Grounded metals

1.0

Ungrounded metals

0.85

Water

1.0

Glass

0.55

Paper (1 ream, 500 sheets)

0.55

Wood

0.45

Stone

0.65

Ceramic tile

0.25

PVC

0.15

Environmental Factors

Capacitive sensors can be compromised by humidity as well

as moisture on the sensor’s face. Oil or water droplets on the

sensor face can cause the unit to become unstable. Dust and

moisture in the atmosphere have less of an effect on

unshielded sensors than on shielded models.

Mounting Considerations

The control must be securely mounted on a firm, stable

surface or support. A mounting configuration which is unstable

or subject to excessive vibration may cause intermittent

operation.

Shielded vs. Unshielded

Shielded sensors can be mounted flush with surrounding

materials. Unshielded sensors must be mounted such that the

area around the sensing face is free of any material which

could trigger the sensor. Minimum clearance in all directions

should be equal to the diameter or width of the sensor.

Spacing Between Devices

When two shielded or unshielded sensors are facing each

other, they must be mounted far apart to avoid interference.

Minimum spacing should be eight times the housing diameter

or width. When two shielded sensors are mounted side by

side, the minimum distance between them must be greater

than one diameter or width. When two unshielded sensors are

mounted side by side, the distance between them should be

at least four times their diameter or width. See Dimensions

section for housing sizes.

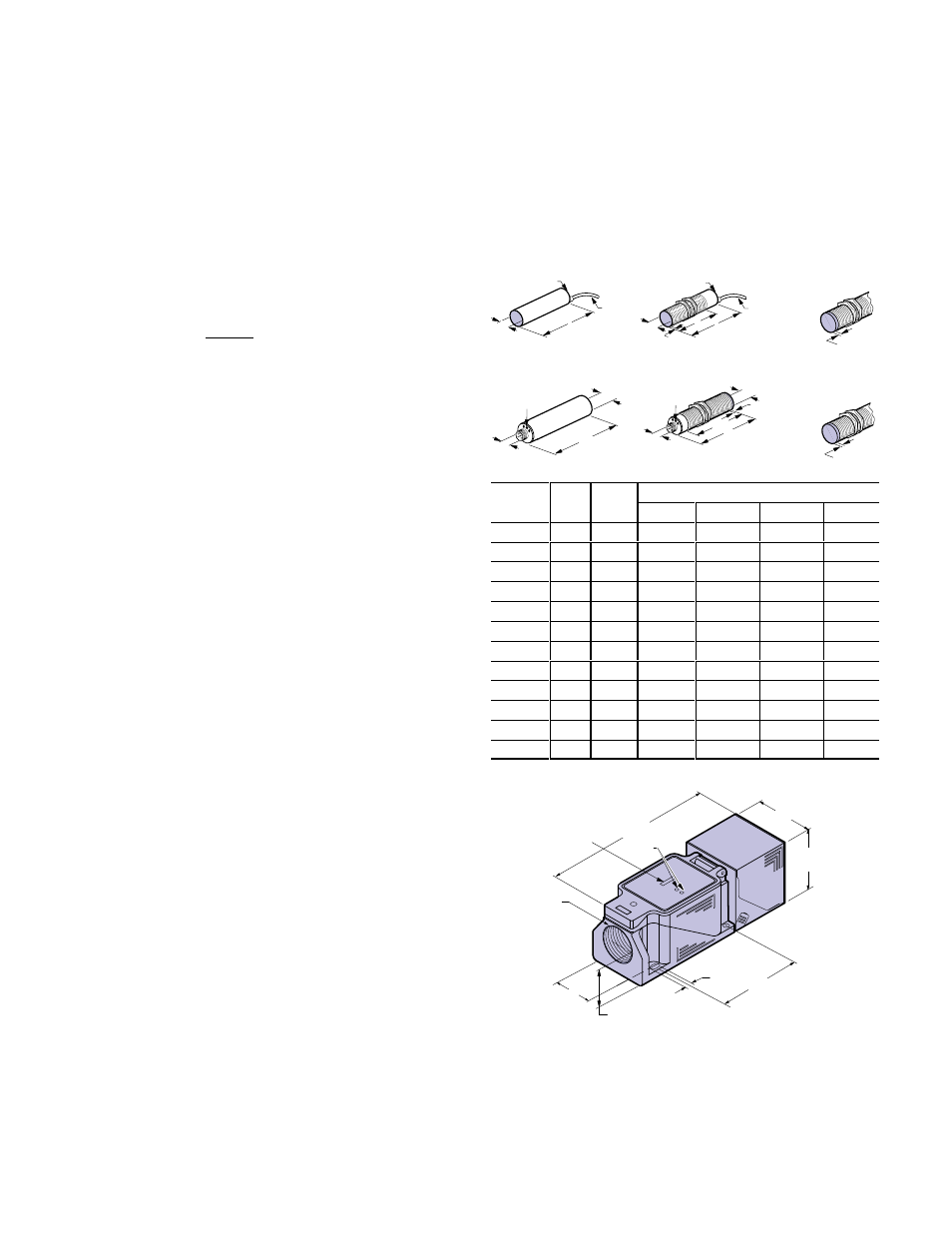

Dimensions

Cylindrical Style

Potentiometer

and LEDs

B

A

2m

(6.5ft)

Potentiometer

and LEDs

C B

D

A

2m

(6.5ft)

D

Unshielded

Threaded

Version

M12 x 1

M8 x 1 (pico)

M12 x 1 (micro)

C

B

A

Potentiometer

and LEDs

D

A

B

Potentiometer

and LEDs

Unshielded

Threaded

Version

D

mm(inches)

Thread

Shld

Conn.

A

B

C

D

M12x1

Y

cable

12(0.47)

61.5(2.42)

40.5(1.59)

N/A

M12x1

Y

pico

12(0.47)

63.5(2.50)

40.5(1.59)

N/A

M18x1

Y

cable

18(0.71)

81.7(3.22)

60.7(2.39)

N/A

M18x1

Y

pico

18(0.71)

81.7(3.22)

60.7(2.39)

N/A

M18x1

N

cable

18(0.71)

81(3.19)

60(2.36)

20(0.79)

M18x1

N

pico

18(0.71)

81(3.19)

60(2.36)

20(0.79)

M30x1.5

Y

cable

30(1.18)

82(3.23)

61(2.40)

N/A

M30x1.5

Y

micro

30(1.18)

82(3.23)

61(2.40)

N/A

M30x1.5

N

cable

30(1.18)

80.5(3.17)

59(2.32)

20(0.79)

M30x1.5

N

micro

30(1.18)

80.5(3.17)

59(2.32)

20(0.79)

N/A

N

cable

34(1.34)

85(3.35)

N/A

N/A

N/A

N

micro

34(1.34)

82(3.23)

N/A

N/A

Limit Switch Style

120.0

(4.72)

LEDs

41.5

(1.63)

41.5

(1.63)

Conduit Entrance

1/2-14 NPT

15.9

(0.63)

30.0

(1.18)

60.0

(2.36)

7.3

(0.29)

Note:Head can be rotated in 15

°

increments to provide 24 sideĆ

sensing positions or rotated for top sensing.

NO/NC and PNP/NPN

Selector Switches