Maximum torque specification, Minimum distance between sensors, Misalignment curve – Rockwell Automation 440N SensaGuard Magnetically Coded NonContact Switch (MC2) User Manual

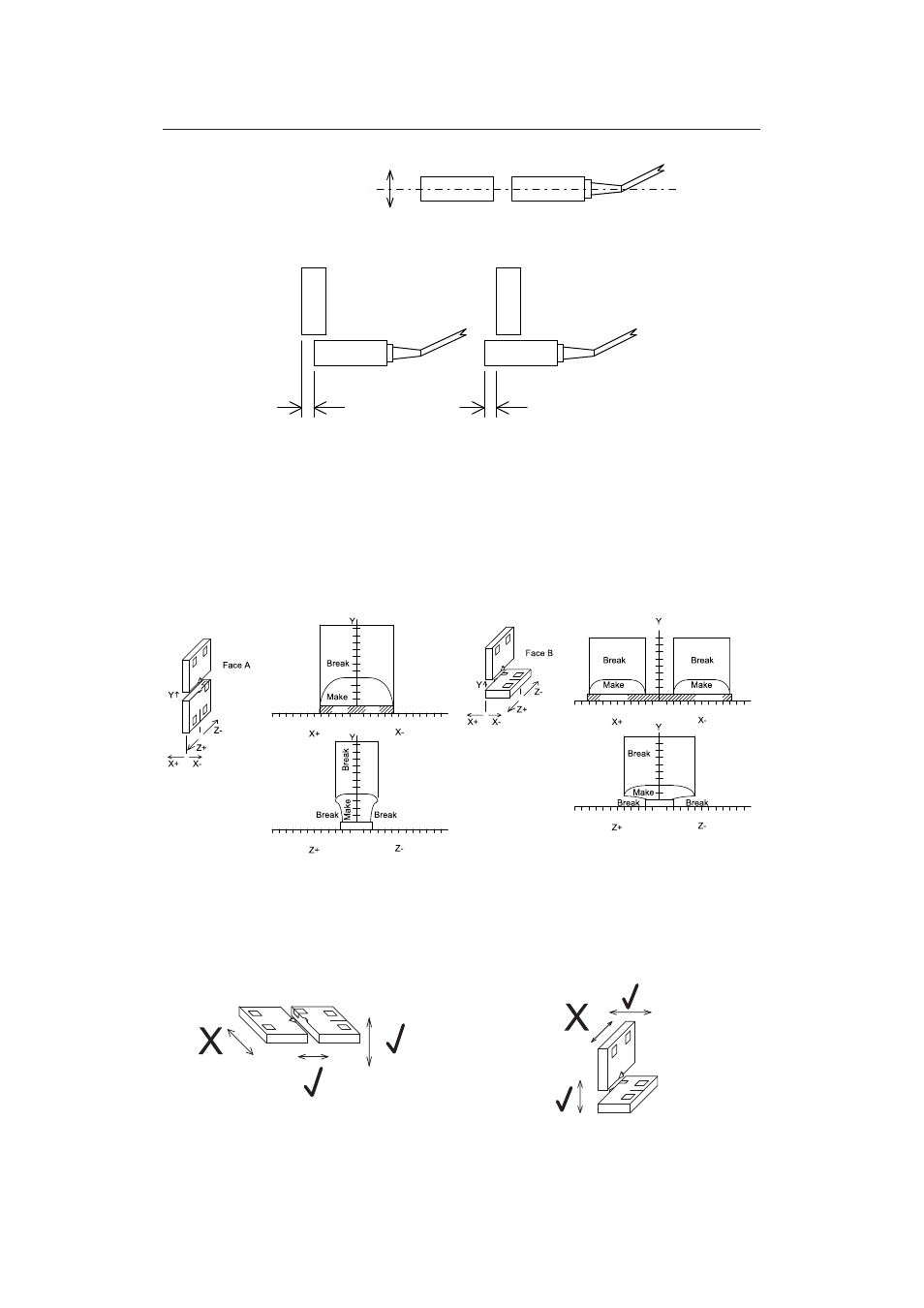

Page 5: Direction of approach, 50mm

4.2

Maximum Torque Specification

- 1 N

•

M (8.86 in

•

lbs), use non-magnetic fixing hardware.

4.3

Minimum Distance Between Sensors

- 50mm

4.4

Misalignment Curve

4.5.

Direction of Approach

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 5

0

0

0

-4

-8

-12

-16

-20

4

8

-24

12

16

20

4

8

12

16

0

-4

-8

-12

-16

-20

4

8

-24

12

16

20

4

8

12

16

20

24

20

24

2mm Gap

2mm Gap

0

0

0

-4

-8

-12

-16

-20

4

8

-24

12

16

20

4

8

12

16

0

-4

-8

-12

-16

-20

4

8

-24

12

16

20

4

8

12

16

20

2mm Gap

2mm Gap

2mm Gap

Note: Refer to Technical Specifications for Certification information and ratings.

Sensor

Sensor

Ac

tu

a

to

r

Ac

tu

a

to

r

Sensor

Actuator

To obtain maximum switching

distance center switches +/- 4mm

To prevent damage it is recommended that a 2mm gap

be maintained between the actuator and sensor

To prevent damage it is recommended

between the actuator and sensor

For more detailed misalignment characteristics refer to the misalignment curves

that a 2mm gap be maintained

distance 8 - 14 mm

To obtain maximum switching

distance 8 - 14 mm

Note: To prevent damage to the MC2 it is recommended to leave a 2mm gap between the Sensor and Actuator.

The maximum switching distance and misalignment tolerance will be obtained when the MC2 is mounted on non-fer-

rous material. Mounting the MC2 on ferrous/magnetic material will reduce the switching distances and tolerance to

misalignment.