Caution – Rockwell Automation 140U Q, M frame CB Electronic RMS Trip Unit installation and operation User Manual

Page 5

Page

5

Contact

Base

Right

Contact

Base

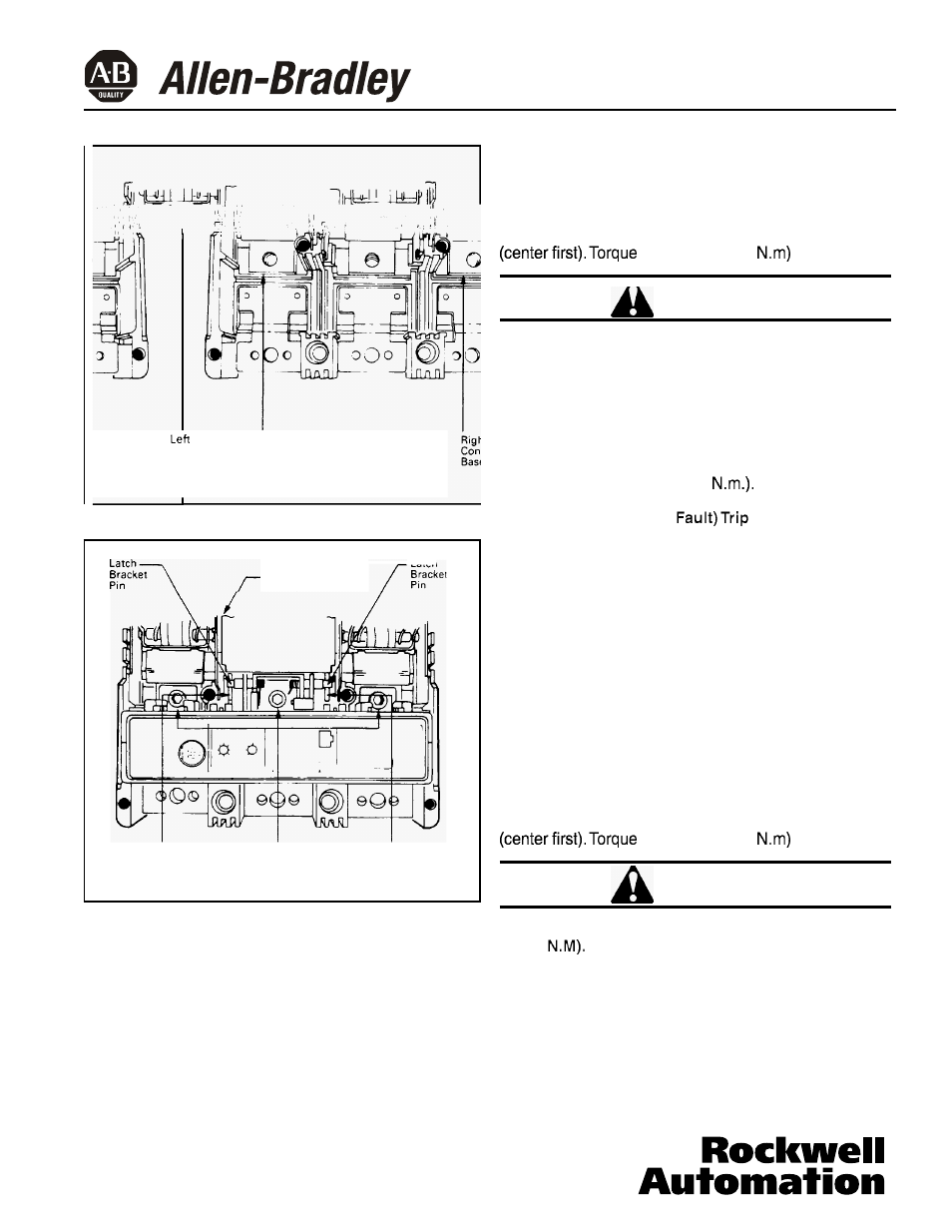

Fig. 7

Left- and Right-Pole Contact Bases

Circuit

Latch

Breaker

Handle

Side

Trip

Side

Plate

Unit

Plate

Retaining

Screws

Position trip unit in base. Make sure latch bracket pin is

properly seated in slots in side plates (see Fig. 8). If

necessary, move latch toward load end of circuit breaker

to seat trip unit.

Screw in and tighten three trip unit retaining screws

to 12 Ib-ft (16.27

(see Fig. 8).

A

CAUTION

DO NOT EXCEED A TORQUE OF 12 LB-FT

(16.27 n.m.) EXCESSIVE TORQUING WILL SHEAR

SCREWS.

FAILURE TO APPLY THE REQUIRED TORQUE MAY

LEADTO EXCESSIVE HEATING AND CAUSE

NUISANCE TRIPPING OF THE CIRCUIT BREAKER.

For an M-Frame, also screw in and torque the load end

screws to 6-8 Ib-ft. (8.14-10.85

3.4 3-Pole (Non-Ground

Unit Installation

Remove trip unit outer pole screws and red plastic

washers from the breaker frame. Discard red plastic

washers (fig. 7). For the M-Frame, also remove the load

end trip unit mounting screws from the frame

(fig. 7a).

NOTE: The two

trip unit outer retaining screws may

be placed

in

the trip

unit conductor holes at this time.

If preferred, the 5/16 inch hexagonal-head wrench may

be used

to position the screws when the

trip unit is

in

the base.

Position trip unit in base. Make sure latch bracket pin is

properly seated in slots in side plates (see Fig. 8). If

necessary, move latch toward load end of circuit breaker

to seat trip unit.

Screw in and tighten three trip unit retaining screws

to 12 Ib-ft (16.27

(see Fig. 8).

CAUTION

Fig.

8

Trip Unit Installed in Circuit Breaker

Note: The two

trip unit outer retaining screws may be

placed

in

the trip

unit conductor holes at this time. If

preferred, the 5/16 inch hexagonal-head wrench may

be used

to position the screws when the

trip unit is

in

the base.

DO NOT EXCEED A TORQUE OF 12 LB-FT

(16.27

EXCESSIVE TORQUING WILL SHEAR

SCREWS.

FAILURE TO APPLY THE REQUIRED TORQUE MAY

LEADTO EXCESSIVE HEATING AND CAUSE

NUISANCE TRIPPING OF THE CIRCUIT BREAKER.

40752-072(2)

Effective

6/02