Troubleshooting, Introduction – Rockwell Automation 281E ArmorStart EtherNet/IP - Getting Started User Manual

Page 28

28 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Publication 280E-QS001B-EN-P – February 2011

Troubleshooting

Introduction

The purpose of this section is to assist in troubleshooting the ArmorStart®

Distributed Motor Controller using the LED Status Display and diagnostic

parameters.

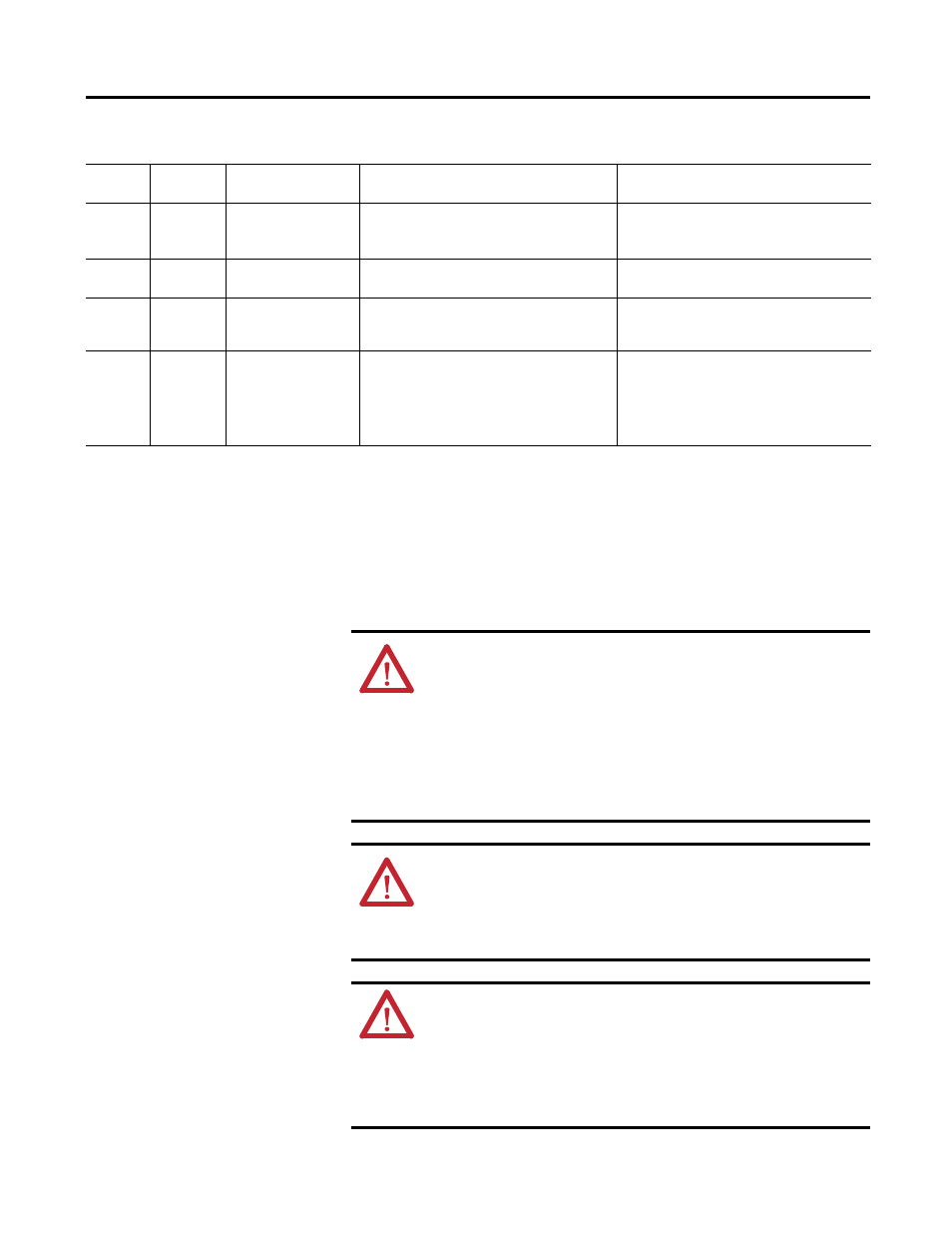

13

No

EEprom

(PF Drive Code

Reference 100)

The checksum read from the board does not

match the checksum calculated.

Set Parameter 141 (Reset to Defaults) to

Option 1 “Reset Defaults”.

14

No

Hdw Flt (PF Drive Codes

Reference 70 and 122)

Failure has been detected in the drive power

section or drive control and I/O section.

1. Cycle power.

2. Replace drive if fault cannot be cleared.

15

Drive

Controlled

Restart Retries (PF

Drive Code Reference

33)

Drive unsuccessfully attempted to reset a fault

and resume running for the programmed number

of Parameter 192 (Auto Rstrt Tries).

Correct the cause of the fault and manually

clear.

16

Drive

Controlled

Misc. Fault (PF Drive

Code Reference 2, 8,

29, 48 and 80)

Heatsink temperature exceeds a predefined

value. The drive was commanded to write

default values to EEprom. The autotune function

was either cancelled by the user or failed.

Check for blocked or dirty heat sink fins. Verify

that ambient temperature has not exceeded

40°C (104°F).

1. Clear the fault or cycle power to the drive.

2. Program the drive parameters as needed.

Restart procedure.

Table 9 - Fault LED Indicators for 284E

Bit/Blink

Pattern

Auto-

Resettable

284E Trip Status

Description

Action

ATTENTION: Servicing energized industrial control equipment can be

hazardous. Electrical shock, burns or unintentional actuation of controlled

industrial equipment may cause death or serious injury. For safety of

maintenance personnel as well as others who might be exposed to

electrical hazards associated with maintenance activities, follow the local

safety related work practices (for example, the NFPA70E, Part II in the

United States). Maintenance personnel must be trained in the safety

practices, procedures, and requirements that pertain to their respective

job assignments.

ATTENTION: Do not attempt to defeat or override fault circuits. The

cause of the fault indication must be determined and corrected before

attempting operation. Failure to correct a control system of mechanical

malfunction may result in personal injury and /or equipment damage due

to uncontrolled machine system operation.

ATTENTION: The drive contains high voltage capacitors that take time to

discharge after removal of mains supply. Before working on drive, ensure

isolation of mains supply from line inputs (R, S, T, [L1, L2, L3]). Wait three

minutes for capacitors to discharge to safe voltage levels. Failure to do so

may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.