Brady X-Plus II User Manual

Page 155

145

Troubleshooting

Print Quality Problems

1/11/07

X-Plus II User Guide

14068L-001 Rev. A

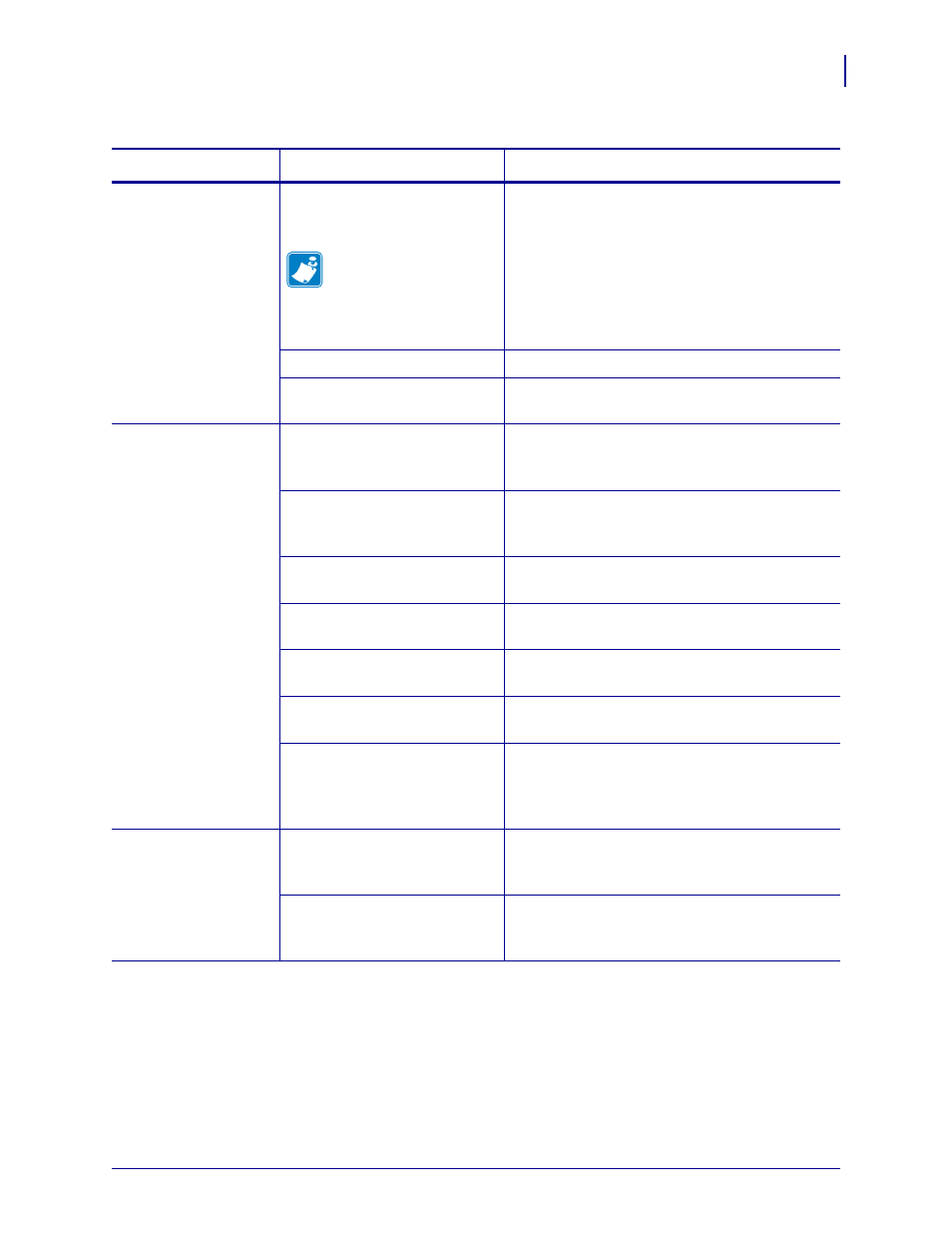

Vertical drift in

top-of-form position

Normal tolerances of

mechanical parts and printer

modes.

Note •

A vertical drift of

± 4 to 6 dot rows

(approximately 0.5 mm)

is within normal

tolerances.

1.

Calibrate the printer.

2.

Adjust the label top position setting. See

Adjust Label Top Position on page 82

.

The printer is out of calibration.

Recalibrate the printer.

The platen roller is dirty.

Clean the platen roller. See

Vertical image or

label drift

The printer is using

noncontinuous labels but is

configured in continuous mode.

Configure the printer for non-continuous and run

calibration routine, if necessary.

The media sensor is positioned

incorrectly.

Ensure that the media sensor is properly

positioned to read a single/consistent interlabel

gap.

The media sensor is calibrated

improperly.

See

Calibrate Media and Ribbon Sensor

The platen roller is dirty.

Clean the platen roller. See

Improper printhead pressure

settings (toggles).

Adjust the printhead pressure to ensure proper

functionality.

Improperly loaded ribbon or

media.

Verify that the printer is loaded properly.

Incompatible media.

Ensure that the interlabel gaps or notches are 2 to

4 mm and consistently placed. Media must not

exceed minimum specifications for mode of

operation.

The bar code printed

on a label does not

scan.

The bar code is not within

specifications because the print

is too light or too dark.

Perform the

the darkness or print speed settings as necessary.

Not enough blank space around

the bar code.

Leave at least 1/8 in. (3.2 mm) between the bar

code and other printed areas on the label and

between the bar code and the edge of the label.

Table 12 • Print Quality Problems (Continued)

Problem

Possible Cause

Recommended Solution