Cleaning schedule – Brady X-Plus II User Manual

Page 134

Routine Maintenance

Cleaning Schedule

124

14068L-001 Rev. A

X-Plus II User Guide

1/11/07

Cleaning Schedule

Cleaning your printer regularly maintains print quality and may extend the life of the printer.

The recommended cleaning schedule is shown in

. See the following pages for

specific procedures.

Caution • Use only the cleaning agents indicated. Brady is not responsible for damage

caused by any other fluids being used on this printer.

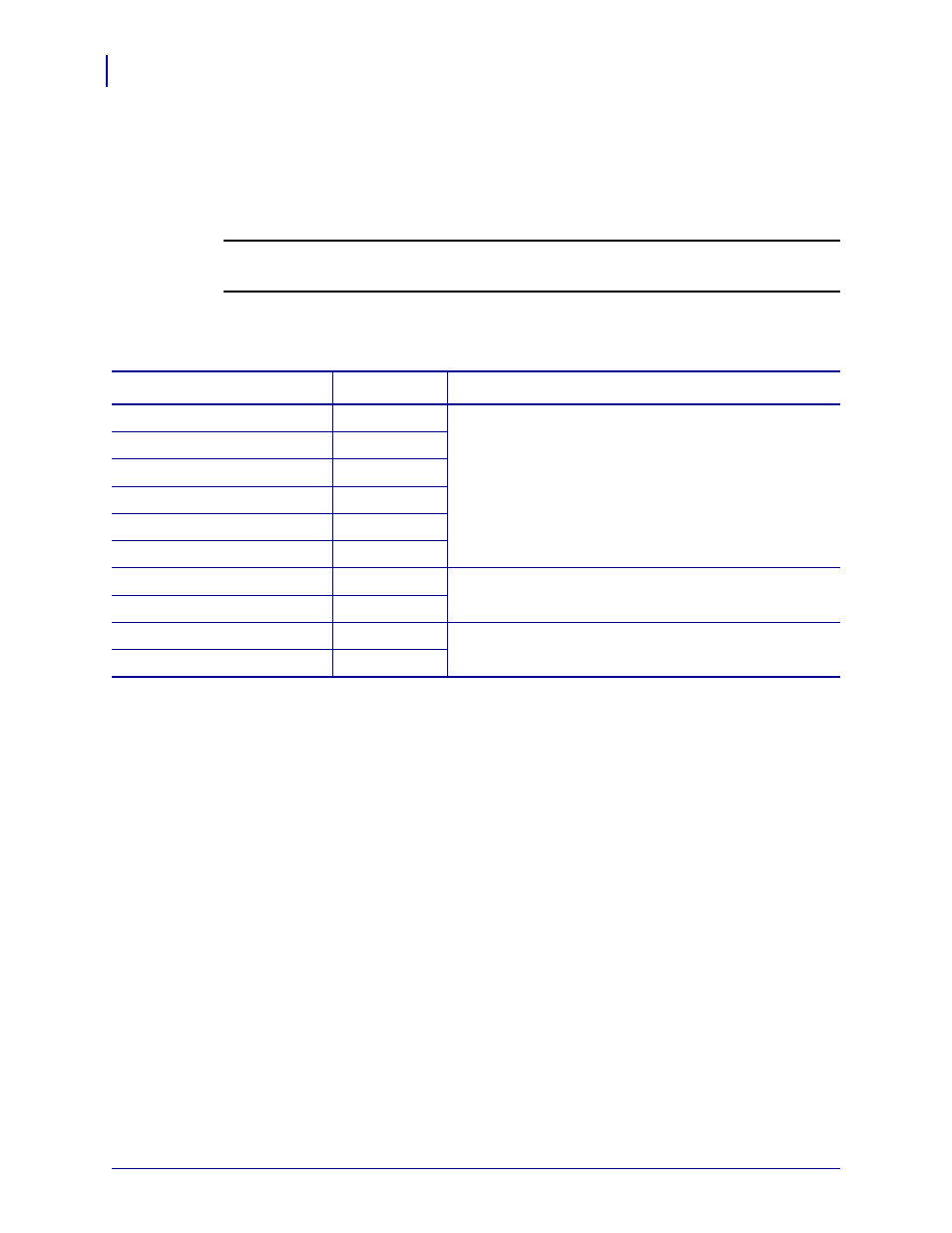

Table 10 • Recommended Printer Cleaning Schedule

Area

Method

Interval

Printhead

Solvent*

Perform these procedures at the following times:

• When

CLEAN HEAD NOW

appears.

• Direct Thermal Print Mode: After every roll of

labels or 500 ft (150 m) of fanfold labels.

• Thermal Transfer Print Mode: After every roll

(1500 ft or 450 m) of ribbon.

Platen roller

Solvent*

Transmissive (media) sensor

Air blow

†

Black mark sensor

Air blow

†

Media path

Solvent*

Ribbon sensor

Air blow

Label-available sensors

Air blow

Every 6 months, or as needed

Tear-off/peel-off bar

Solvent*

Snap plate

Solvent*

As needed

Cutter

Solvent*

* Brady recommends using Preventive Maintenance Kit (part number PCK-4). In place of this kit, you may use a clean swab

dipped in a solution of isopropyl alcohol (minimum 90%) and deionized water (maximum 10%).

† If using canned air, it is recommended that you turn off the printer before cleaning.