USG SHEETROCK Setting-Type Joint Compounds DURABOND User Manual

Page 2

Use with S

HEETROCK

In areas to be tiled, for tapered edge joints, embed S

HEETROCK

Brand Joint Tape with S

HEETROCK

Brand D

URABOND

Brand Gypsum Panels,

Setting-Type Joint Compound (45 or 90). When set, apply a fill coat of D

URABOND

45 or 90. Take care not to

Water-Resistant

crown the joint. Wipe excess joint compound from the panel surface before it sets. For butt joints and interior

angles, embed S

HEETROCK

Brand Joint Tape with D

URABOND

45 or 90. A fill coat is not necessary. Again, take care

not to crown the joint. For fasteners, spot fastener heads at least once with D

URABOND

45 or 90.

Fill and seal all openings around pipes, fittings, and fixtures with a thinned-down coat of tile adhesive. For best

results, use Type I Ceramic Tile Adhesive that meets ANSI A136.1 both as a sealer and to set the tile. With a

1

Љ brush, apply the thinned compound onto the raw gypsum panel core at cutouts, and allow area to dry

thoroughly prior to application of tile. Before compound dries, wipe excess material from the surface of gypsum

panels. For areas not to be tiled, embed tape with D

URABOND

45 or 90 in the conventional manner. Finish with at

least two coats of a S

HEETROCK

Brand Joint Compound to provide joint finishing for painting and wallpapering.

Laminating

Apply S

HEETROCK

Brand Setting-Type Joint Compound in the prescribed manner to back of face panels to be

laminated. Laminate face panels to (base layer panels) (coreboard) using moderate pressure and temporary

nailing or shoring to ensure adequate bond.

Repairing Handball

Repair surface-damaged areas (gouges, scratches, surface imperfections) in handball and racquetball court

and Racquetball

walls and other interior wall and ceiling surfaces finished with U.S. Gypsum S

TRUCTO

-B

ASE

®

and S

TRUCTO

-G

AUGE

®

Court Walls

Gypsum Plasters as follows. Clean surface of dust, residue, and other contaminants. Prepare D

URABOND

45 or 90

by mixing into a solution of 1 part water and 1 part USG A

CRI

-A

DD

™

100% Acrylic Add-Mix Fortifier. Use prepared

mixture to refinish surface damage. Initial application over deep areas should be set and partially dry prior to

application of subsequent coats. Finish to a smooth surface. This same procedure may be used in repair of

surface-damaged areas of S

TRUCTOCORE

®

Security Wall Systems constructed using S

TRUCTO

-B

ASE

Gypsum Plaster

and I

MPERIAL

®

Finish Plaster per publication SA1119.

Finishing

For painting and decorating, follow manufacturer’s directions for materials used.

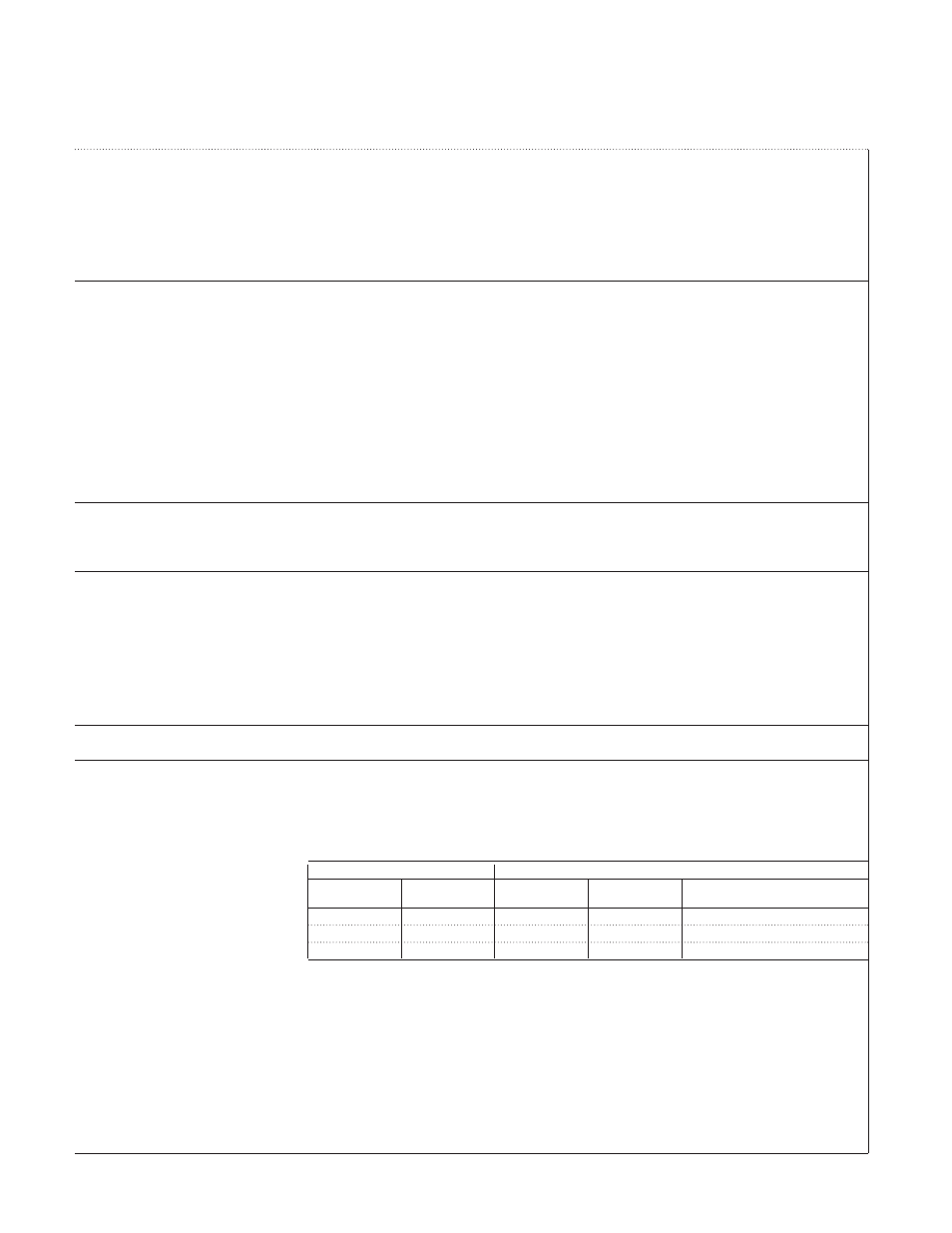

Use With USG

USG Gypsum Accelerator (High Strength) when added to S

HEETROCK

Brand Setting Type Joint Compound

Gypsum

(D

URABOND

) will shorten the setting time. USG Gypsum Accelerator should be sprinkled in dry form into the mixed

Accelerator

compound. For hand mixing, dry accelerator can be added either to the dry mix or mixed compound. Never add

USG Gypsum Accelerator directly to water or mix it with water to form a solution before adding it to the compound.

Doing so will significantly reduce its ability to accelerate the set.

Accelerator Amount

Approximate Set Time (minutes)

Tablespoon

Tablespoon

D

URABOND

90

D

URABOND

45

D

URABOND

20

Per Bag

Per Bread Pan

1.0

0.22

40

20

10

2.0

0.44

30

10

6.0

1.33

20

– “Bread Pan” volume estimated at 10 cups (80 oz.)

– Wet Mixed Volume of Setting Type Joint Compounds approx. 2.8 gallons (45 cups) per bag.

Page 2 of 3