Expansion characteristics – USG HYDROCAL Gypsum Cements User Manual

Page 2

Expansion Characteristics

continued

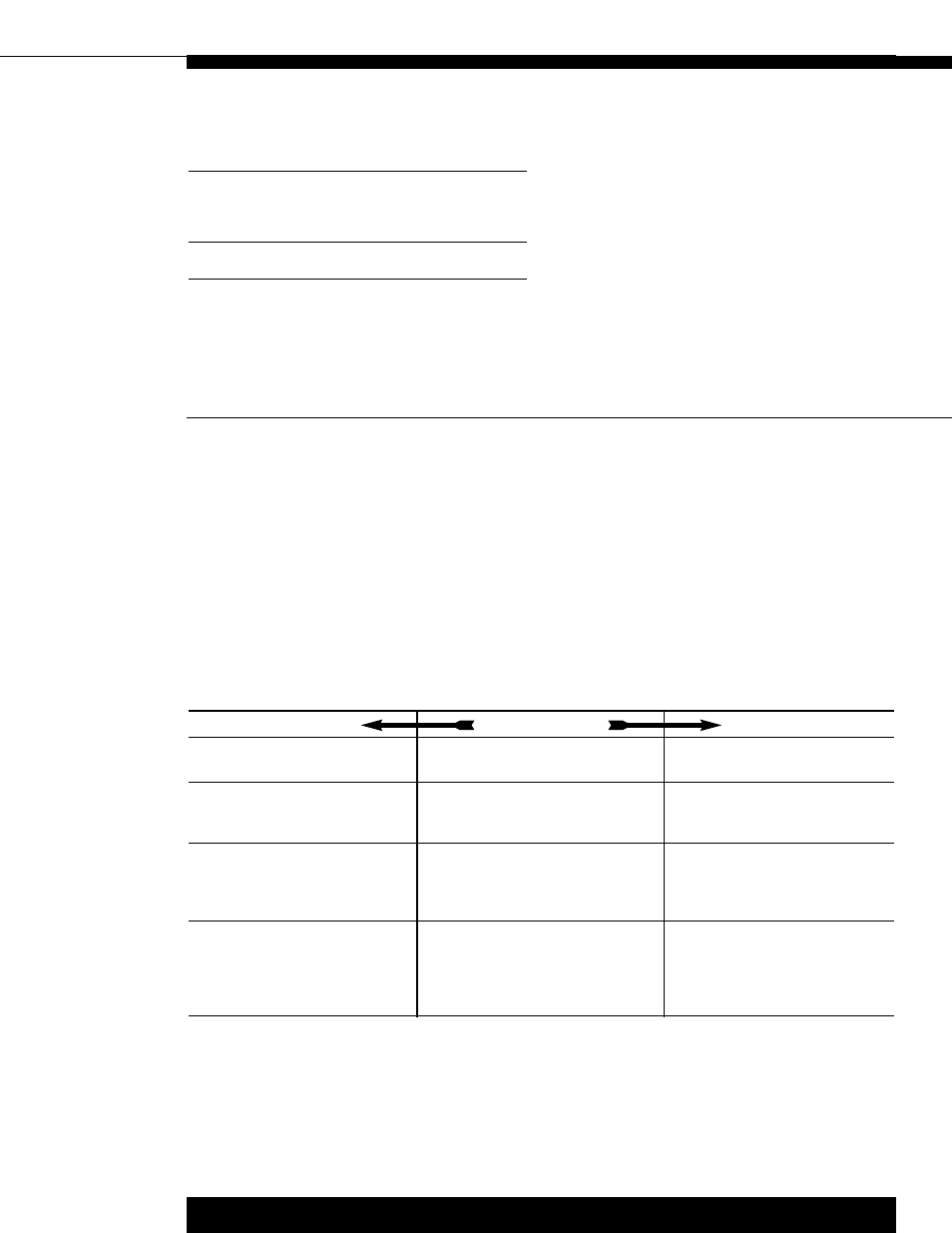

Recommended Proportions for

Medium High-Expansion Cement

Parts

Medium High-Expansion

Parts

Maximum

Gypsum Cement

Water

Expansion

(by weight-lb.)

(by weight-lb.)

(in. per ft.)

100

48-50

1/8

100

44-45

3/16

Casts must be a min. of 4 to 5-in. in depth to obtain these

values. Expansion values can be increased 10 to 15 percent

by using hot water (120° to 130°F for a slurry temperature of

100° to 110°F).

Mixing

W

eigh expansion plaster and water as recommended and

strew plaster into water as evenly as possible. Allow

plaster to soak for a few minutes; with heavier mixes,

however, there will not be enough water to completely

soak the plaster.

With hand mixing, force plaster into water and mix

vigorously until a smooth mass is obtained. For mixes

from 10 to 15 lbs., a

1

⁄

4

-in. drill motor with a 4-in. disc

has been found to be far superior to hand mixing.

Where larger machine mixing is used, a planetary-action

batch mixer equipped with a bar-type agitator is

recommended.

Lower

Expansion

Greater

Approx. Lower Limits

Controllable

Approx. Upper Limits

and Effects

Variables

and Effects

About 60 cc

Consistency

About 40 cc

Over this amount material too

(Parts of water to 100 lb. H

YDROCAL

Below this amount material too

watery and slow set

by weight)

pasty to handle

About 1 Min.

Mixing Time

About 5 Min.

Unmixed lumps giving variable

(Mechanical mixer of appropriate size

Extremely fast set. Danger of mixing

expansion and sets

operating at approximately 1,760 rpm)

through set and disrupting structure

so no set or strength will result

About 32°F.

Slurry Temperature

About 110°F.

(Temperature of H

YDROCAL

Above this temperature set is

and water combined)

retarded. Up to this temperature

set is accelerated and may become

too fast for use.

United States Gypsum Company

Industrial Gypsum Division

125 South Franklin Street

Chicago, IL 60606-4678

Technical Assistance: (800) 487-4431

IG-540/rev. 5-95 Printed in U.S.A.

Copyright 1995, United States Gypsum Company