USG Exposed Hanger Solutions User Manual

Page 2

Page 2 of 4

Connection Spacing and

Infill Panel Options

System Weight

Maximum Uniform Load On Carriers (lbs./lin. ft.)

Termination Method

(lbs./sq. ft.)

Hanger Spacing (along main tee or carrier)

4 3 2

C

urvatura

System

Aluminum (solid and perforated)

0.5

7.5

10

15

D

iamonDflex

0.6

7.5

10

15

Brass and Stainless Steel wire mesh

0.6

7.5

10

15

t

ransluCents

(Lexan or FRP)

0.6

7.5

10

15

L

ibretto

Gridless Metal

Solid

and

perforated

0.6

7.5

10

—

Ceiling System

t

opo

System

t

opo

infill

0.5

7.5

10

15

Trim

(lbs./lin. ft.)

4 3 2

C

2

Paired C

ompässo

Channels 8

3.5

7.5

10

15

Notes:

– Quality of wire connection can very widely depending on field conditions, equipment and user experience.

Installer must determine safe connection spacing and means for loads to be encountered.

–

30 lbs. per 18-gauge wire and 1/32 stainless steel rope wire is the maximum recommended load including

any additional or live load during installation.

– Suitability of decorative ceiling hanger devices must be determined by user. These are not to be used where

hangers must conform to ASTM C636, “Standard Practice for Installation of Metal Ceiling Suspension System

for Acoustical Tile and Lay-In Panels.”

Installation

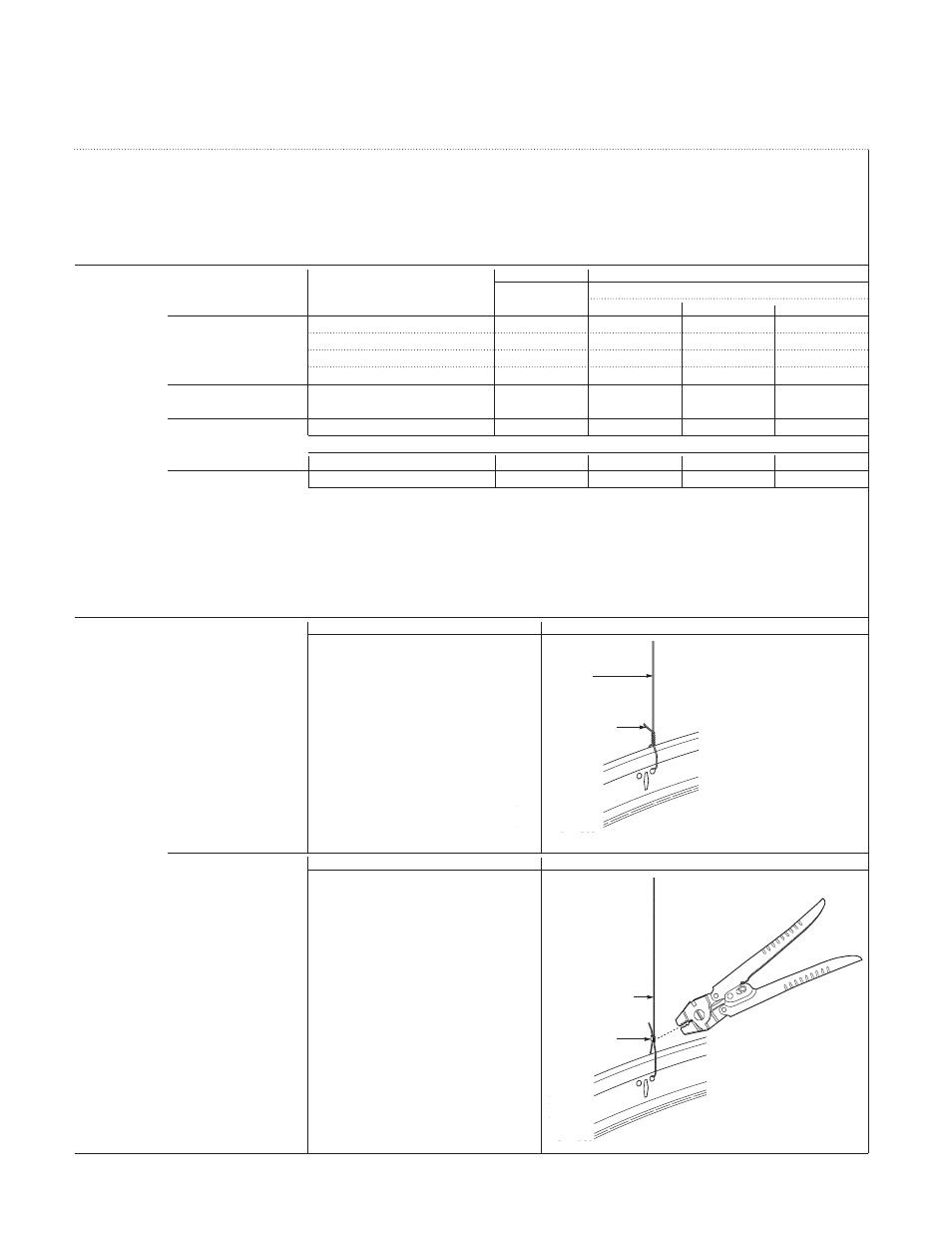

18-Gauge Stainless Steel Twisted-Tie Connection

Detail

Six complete twists inside 1/2, first loop

to third loop.

1/32 Stainless Steel

Loop and Crimp-End Connection

Detail

Rope Wire

Feed rope wire down through one side of

oval crimp (USG Part No. 205241), through

hanger hole on tee or bracket and back up

through other side of oval crimp. Using crimper

(USG Part No. 202880), fully compress oval

two times, one above the other, using smallest

notch of tool. Crimp cannot be undone, so be

sure tee or bracket is in correct location before

pinching oval closed.

wire crimp

1

/

2

" stainless

steel rope wire

wrap wire six

times within

1

/

2

"

18 ga. stainless

steel wire