Pipe seal, Mixing valve seal, Shower walls – USG Durock Shower System User Manual

Page 4: Shower floor

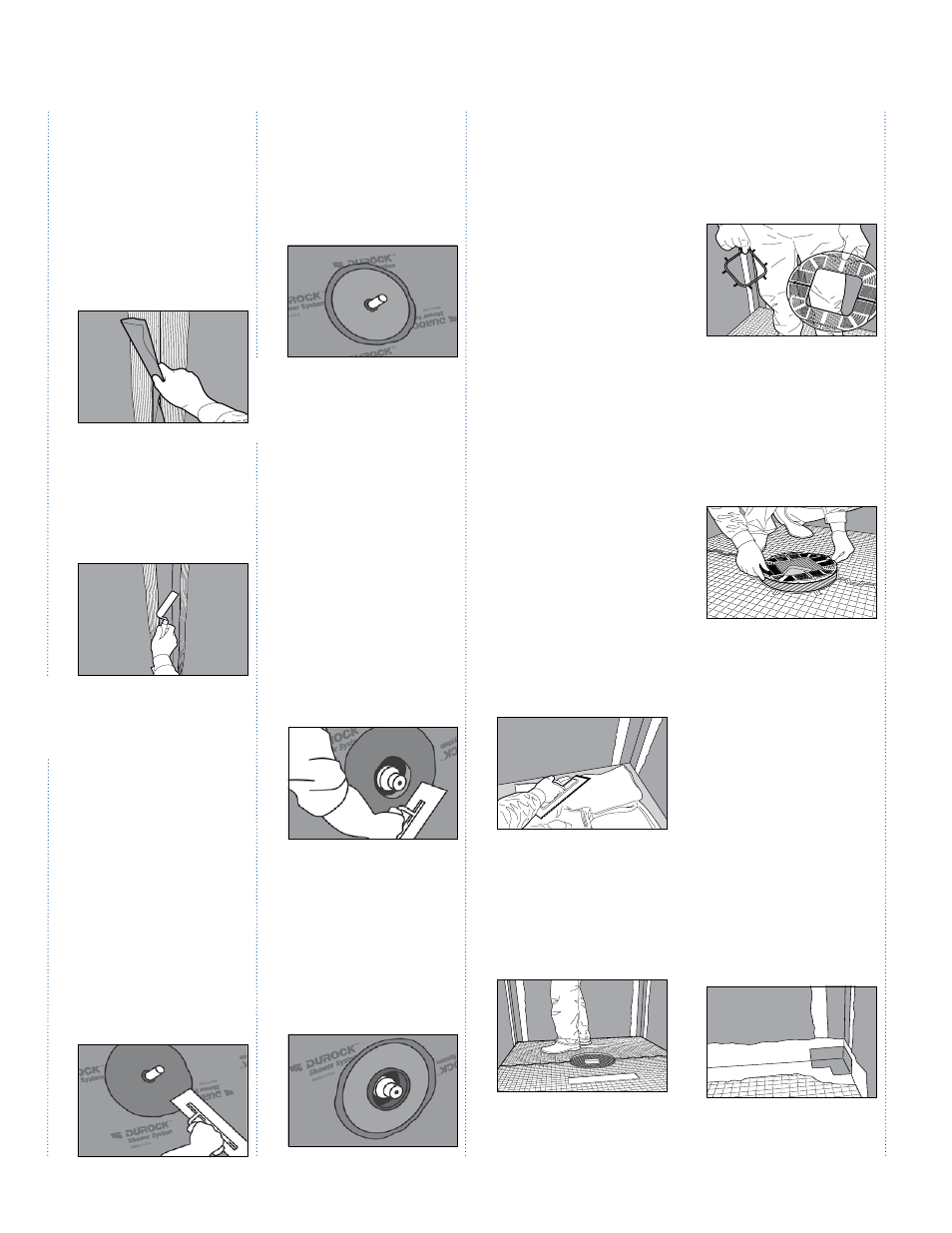

5. Install D

urock

™

Shower

System Waterproofing Band

at all vertical inside wall

corners using unmodified

thin-set mortar and a

3/16" x 3/16" (5 mm x 5 mm)

v-notched trowel or 1/8" x

1/8" (3 mm x 3 mm) square

or u-notched trowel.

Tip: To center waterproofing

band at inside wall corners,

crease waterproofing band by

folding in half lengthwise. Embed

waterproofing band in thin-set

mortar using a drywall taping knife

or margin trowel.

Pipe Seal

D

urock

™

Pipe Seals are designed

to seal pipe penetrations in water-

proof wall assemblies; e.g., pipe

penetrations at shower heads,

tub spouts, body sprays, etc.

1. Apply unmodified thin-set

mortar to the substrate

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

2. Place seal over pipe and

embed into the mortar using

a finishing trowel, drywall

taping knife, or similar tool

to remove air pockets and to

ensure proper adhesion.

Mixing Valve Seal

D

urock

™

Mixing Valve Seals

are designed to seal mixing

valve openings in waterproof

wall assemblies in tub surrounds

and showers.

1. Apply unmodified thin-set

mortar to the substrate

using a 3/16" x 3/16"

(5 mm x 5 mm) v-notched

trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel.

2. Place seal into mixing valve

opening and embed into the

mortar using a finishing trowel,

drywall taping knife, or

similar tool to remove air

pockets and to ensure proper

adhesion.

Shower Walls

cont.

1. Place shower tray disk on

subfloor at desired drain

location. Using the removable

subfloor cutout template on

the shower tray disk, trace

the hole location on the

subfloor before cutting.

Note: Alignment of drain grate

to tile layout must be established

before cutting the hole in the

subfloor.

Tip: Dry-lay the pre-sloped

shower tray, then align the shower

tray disk with the clock marks on

the tray to the desired position

before marking and cutting the

hole in the subfloor.

2. Apply unmodified thin-set

mortar to the subfloor

using a 1/4" x 3/8"

(6 mm x 10 mm) square

or u-notched trowel. Floor

must be level prior to

installation of shower tray.

If necessary, apply D

urock

™

Self Leveling Underlayment

prior to installation.

3. Firmly embed D

urock

™

Shower System Pre-Sloped

Shower Tray into the mortar.

Check underside of tray to

ensure full mortar coverage.

4. Remove integrated cutout

template—used for drain

hole cutout in subfloor—

from shower tray disk prior

to installation.

5. Install shower tray disk by

fully embedding in the thin-

set mortar and positioning to

match drain hole orientation

using the clock marks on the

shower tray.

6. Apply unmodified thin-set

mortar to pre-sloped shower

tray and wall junction using

a 3/16" x 3/16" (5 mm x 5 mm)

v-notched trowel or 1/8" x 1/8"

(3 mm x 3 mm) square or

u-notched trowel. Embed

D

urock

™

Shower System

Preformed Inside Corners

into the mortar, using a

drywall knife or margin

trowel to remove air pockets

and ensure proper adhesion

to shower tray and wall

junction.

Pipe Seal

cont.

Shower Floor

For more detailed instructions visit durockshowersystem.com

3