Fan unit, Air flow up, Field wiring – Titus Fan Powered Term. IOM User Manual

Page 2: Unit labeling, Control start-up, operation, Primary air damper

Field Wiring

All field wiring must comply with the

local codes and with the National

Electrical Code (ANSI/NFPA 70-1996).

Disconnect switches are optional

equipment. Electrical, control, and piping

diagrams are shown on the exterior

labeling or on a diagram on the inside of

the control and high voltage enclosure

covers. Unless specified otherwise in

the order write-up, all units are wired for

a single point electrical connection to the

fan and optional electrical heater. All

electric heaters if provided by TITUS are

balanced by kW per stage. The installing

electrician should rotate incoming

electric service by phase in order to help

balance the building electric load.

Caution—Electrical Requirement:

1. Provide a safety disconnect per

NEC 424-19, 20 & 21.

2. Disconnect all incoming power

before wiring or servicing unit. All

disconnect switches on the terminal

(if so equipped) should be in OFF

position while making power

connections.

3. All field wiring must be in

accordance with NEC and local

code requirements. All units with

electric heat should have copper

wires for 125% of Nameplate

Amperage.

4. Observe wiring diagram and

instructions mounted on the unit.

480 V/3 phase units require a 4th

(neutral) wire in addition to the full

sized ground wire. All units must be

grounded as required by NEC 424-

14 and 250.

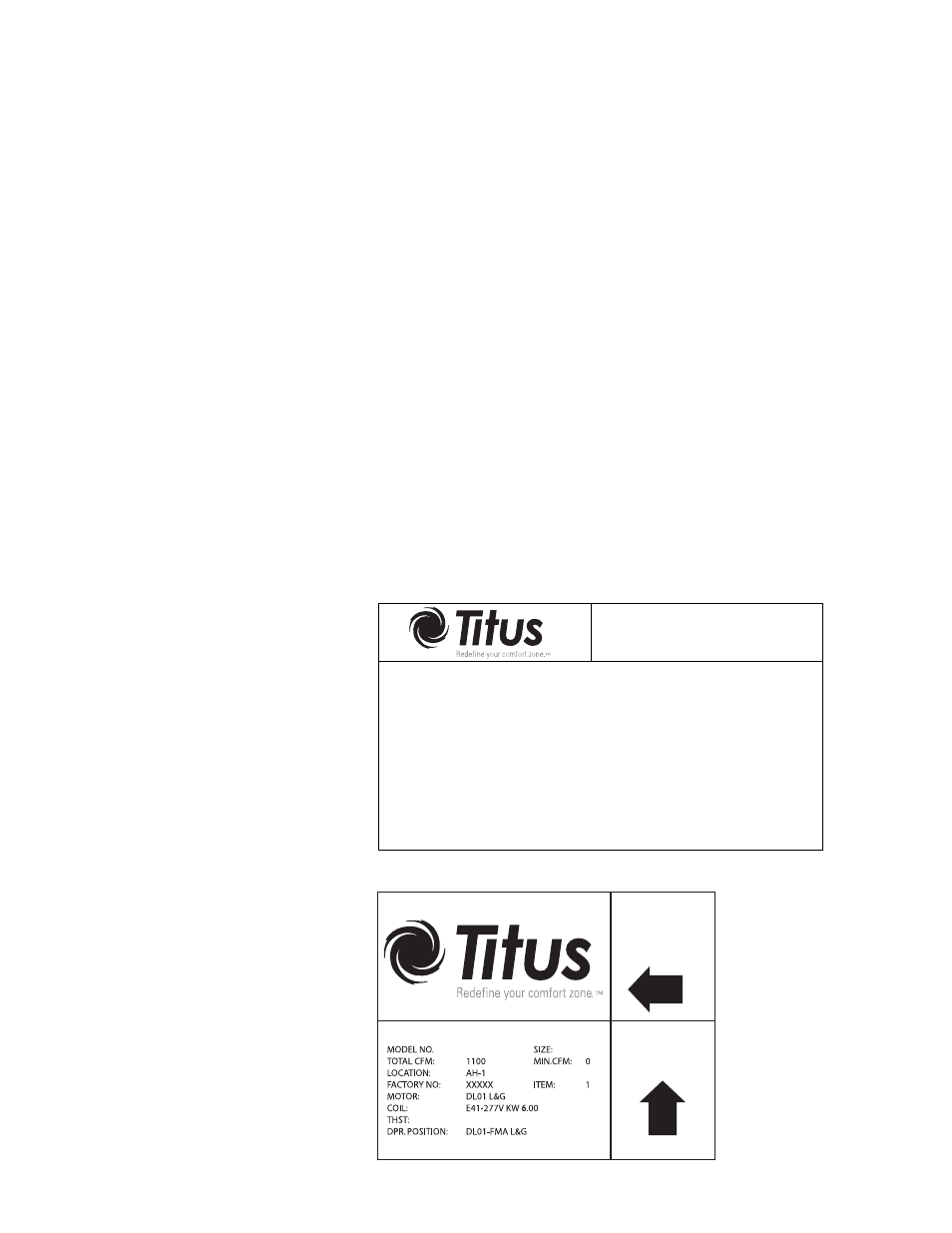

Unit Labeling

Each unit will have two main labels

attached to the casing. The FAN UNIT

label (Figure 3) lists the Model Number,

Supply Voltage requirements, Motor

Horsepower, and Overcurrent Protection

requirements. The AIR FLOW label

(Figure 4) lists the Model Number, Unit

Size, Factory Order Number, and

Location. The Location (or "Tag")

indicates the engineer's planned

location for the unit to be installed.

There may be other labels attached to

the unit, as options or codes may

require.

Please read all labels on a typical

unit, before beginning installation. If

you have any questions, please contact

the local TITUS Representative for

clarification. Have the key points from

the Air Flow label available for reference

before calling.

Control Start-up, Operation

Detailed information regarding power,

accessory

and

communications

connections, start-up and operating

procedures for the TITUS TD-1

controller (digital) or pneumatic and

analog controls are available from your

local TITUS representative. For specific

information on controls by other

manufacturers

contact

that

manufacturer’s local branch or dealer.

Note: Controllers may incorporate

specific

communication

addresses

based on Building Management

Systems Architecture, and original

engineering drawings. Installing the

terminal in a different location than

noted on unit label may result in

excessive start-up labor.

Primary Air Damper

TFS, TQS and TQP Models:

To replace the damper blade and/or

shaft assemblies:

a. Disconnect power before servicing.

Remove control enclosure cover to

access actuator.

b. Note position of damper shaft, using

indicating arrow. Loosen linkage or

actuator collar to allow damper to

rotate freely.

c. Remove bottom access door to

expose damper assembly. Rotate

damper to fully closed position,

exposing rivets holding damper

blade to shafts.

d. Drill out rivets using 1/2” drill, rotate

damper to fully open position, and

slide

damper

and/or

shaft

assemblies out of the duct.

e. Fit new damper and/or shaft

assemblies in place, using 1/4-20

screws with lock nuts to replace

rivets.

f.

Reverse procedure in steps c, b,

and a, for assembly. When locking

down actuator linkage or collar,

position indicating arrow on damper

in the same location as before the

repair.

FLS and FLP Models:

These units use an opposed blade

damper assembly that is not repairable.

The entire assembly must be replaced.

Figure 3. FAN UNIT Label

Figure 4. AIR FLOW Label

TU-FB-IOM 08-26-13

2 of 9

FAN UNIT

MODEL NO.:

DTFS

CODE:

88-XXXXX-A 2 REV: 02

MOTOR

VOLT:

277

PHASE:

1

HZ

60

HP:

1/4

FLA(EA)

1.4

HEAT

VOLT 277

PHASE

1

HZ

60

KW

6.0

AMPS

21.66

MOTOR (S) ARE THERMALLY PROTECTED

MIN. SUPPLY CIRCUIT AMPS:

24 AMP

MAX. FUSE OR OVERCURRENT PROTECTION:

30 AMP

MAX. OUTLET AIR TEMPERATURE:

200F

UNIT DESIGNED TO OPERATE AT NO LESS THAN 0.2 IWG STATIC PRESSURE

ZERO CLEARANCE FROM UNIT, CONNECTED DUCT AND/OR PLENUM

TO COMBUSTIBLE MATERIAL

303155001015

AIR

FLOW

UP

DTFS

C12