Retsch ZM 200 User Manual

Page 23

08.02.2012

Retsch GmbH

23

0003

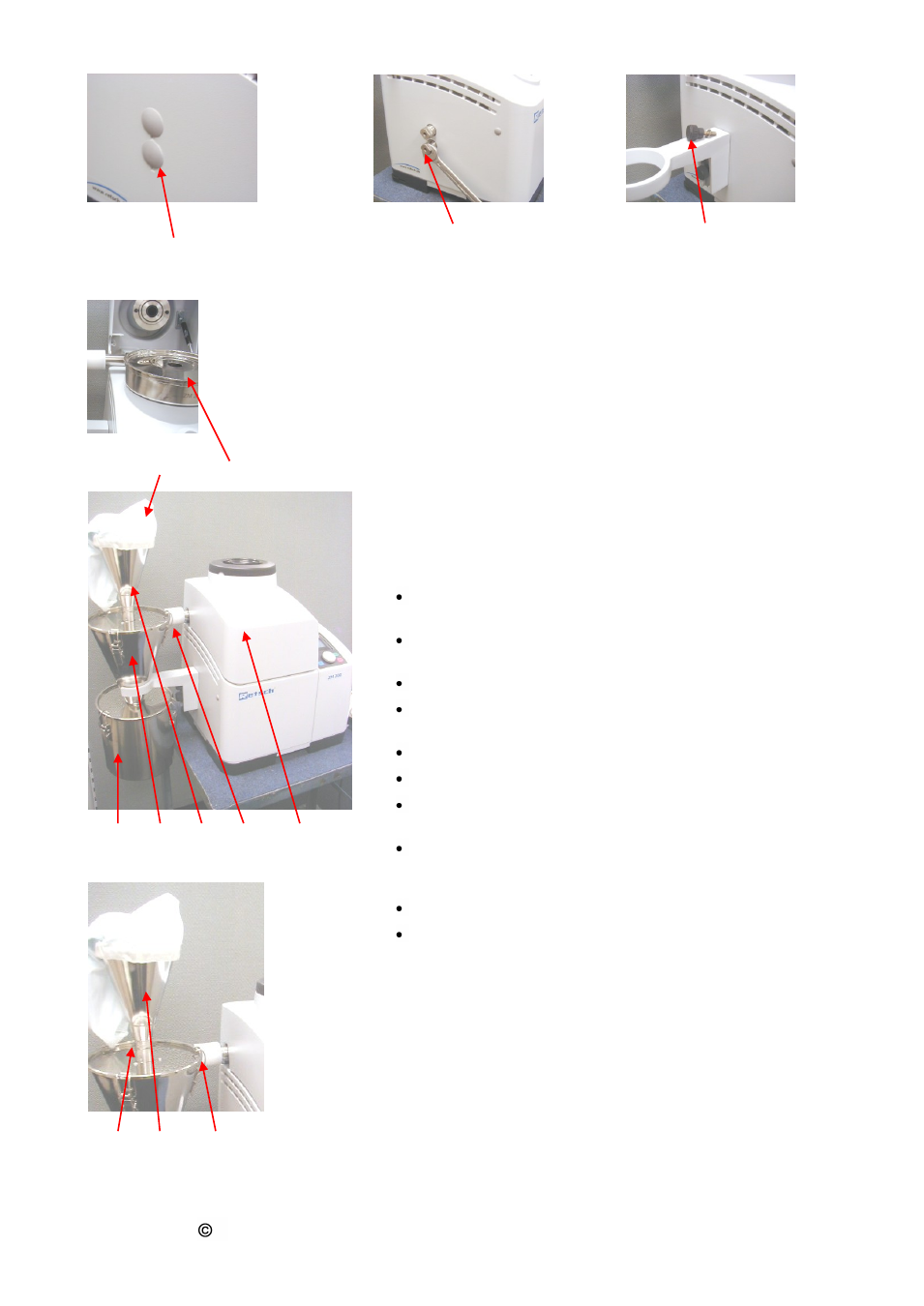

Cyclone separator with collecting container

KS

HB

SC

FS

DG

AB

ZK

TR

KP

GD

RE

TR

ST

If large amounts of material are to be ground, the cyclone

separator allows up to 5000ml of material to be discharged

into its collecting container. For this purpose, there must be

sufficient space on the left-hand side of the table

underneath the ZM200 because the 5000ml collecting

container ends lower than the surface of the table.

However, it is also available with a 3000ml collecting

container if there is no space below on the left-hand side at

the point of assembly.

The air throughput generated in the ZM200 during the

grinding process serves to transport the comminution

material into the collecting container.

The air throughput depends upon the hole width of the ring

sieve.

Assembly procedure

Apply a slotted screwdriver to the indentations in the

housing and remove both plastic plugs KS

Screw in 2x retainer bolts HB with an open-jaw spanner

size 19

Install the retainer and fix with 2x screws SC

Install throughput vessel DG instead of the standard

collecting vessel with ring sieve and cassette cover

Close housing cover GD of the ZM200

Place cyclone ZK in the fork

Connect the cyclone and the throughput vessel with

coupling KP

If necessary, loosen screws SC again and adjust the

height by moving the retainer. The nozzles of the

cyclone and of the collecting vessel should be flush.

Fasten collecting container AB to the cyclone

Slide hopper TR with filter sack FS into the cyclone

The height adjustment of hopper TR influences the degree

of solid/air mixture separation.

The optimum position should be determined empirically in

each case. As a rough guide, pipe end RE of hopper TR

should end slightly below the nozzle ST for feeding material

into the cyclone.

The ZM200 can now be started at the speed you pre-

selected.