Suitable, Comminution material, Comminution methods – Retsch ZM 200 User Manual

Page 20

08.02.2012

Retsch GmbH

20

0003

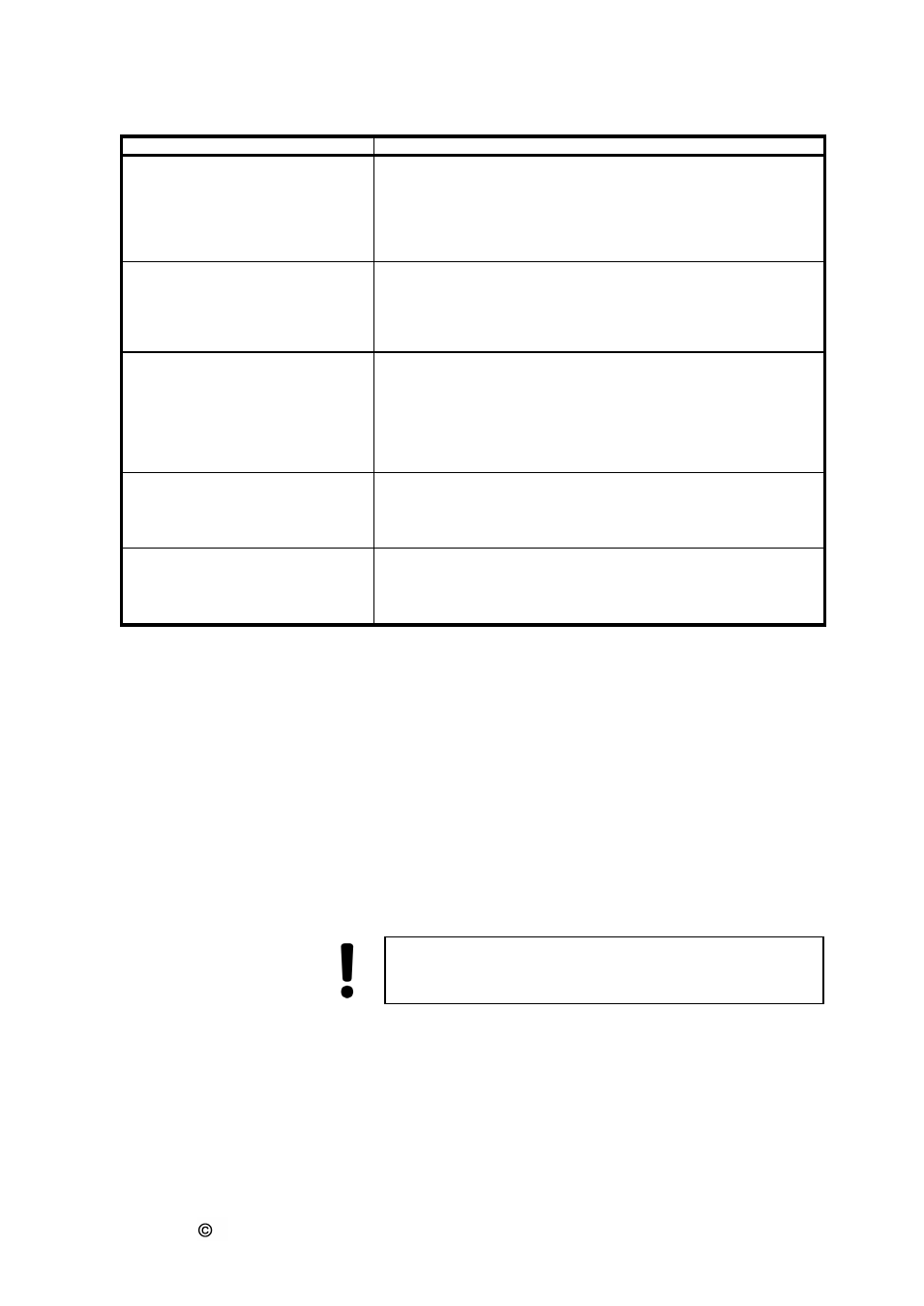

Suitable

comminution material

The listing below shows which grinding tool you should

deploy for which comminution material in order to

achieve an optimum result.

Comminution materials

Grinding tools

Fodder pellets

Drugs

Straw

Dog cake

Spices

Grasses

Paper cellulose

6-tooth rotor

Adapt the ring sieve to the desired end fineness

For preparation of bulky, fibrous comminution material

Cereals

Maize

Tablets

Fibrous foodstuffs

Dragees

Confectionery

12-tooth rotor

Adapt the ring sieve to the desired end fineness

For preparation of fibrous, brittle comminution material

Dolomite

Talcum

Gypsum

Activated carbon

Wood/brown coal

Dry, non-hygroscopic chemicals

Ion exchanger

Sugar beet/cane

24-tooth rotor

Adapt the ring sieve to the desired end fineness

For preparation of medium-hard, brittle comminution material

Minerals with a Mohs' hardness to 4

Ductile metal powder

Compost

Garbage mixtures

Fluorspar/feldspar

Wear-proof coated rotors

Adapt the ring sieve to the desired end fineness

They can be deployed if it is possible that wear on the standard rotor

could have a disturbing influence on the subsequent analysis.

Biological products

Pharmaceuticals

Foodstuffs of all types

Biological research

Titanium rotors (free of heavy metals)

Adapt the titanium ring sieves to the desired end hardness.

They can be deployed whenever heavy metal contamination is

inadmissible. Titanium rotors and ring sieves should not be used for

hard, abrasive mixtures, but only for soft to medium-hard products.

Comminution methods

Ultra-fine grinding with Conidur ring sieves

This process is deployed to exploit the high shearing

power of Retsch-Conidur sieves.

Select the perforation width of the ring sieves in

dependence on the desired end fineness and on the feed

material. For the majority of materials, the fineness

achieved is around 80% smaller than half the perforation

size of the sieves deployed.

Pre-comminution with round hole ring sieves

This process is deployed to pre-grind material such as

fodder pellets, tablets etc..

Never pre-grind without a ring sieve.

The collecting base can suffer serious damage.

The rotor can damage the cassette cover.