Retsch ZM 200 User Manual

Page 21

08.02.2012

Retsch GmbH

21

0003

Comminution by cold grinding

X

Material that cannot be ground at normal room

temperatures, or not at all, must be cold ground. Prior

embrittlement with liquid nitrogen ( -196°C) improves the

breakage behaviour of materials such as thermoplastics,

rubber products, fatty foodstuffs, pharmaceuticals etc.

Embrittlement with liquid nitrogen is not necessary in the

majority of cases. Mixing with dry ice also produces good

results, as does storing the comminution material in a

freezer for 24 hours at a temperature of least -19°C.

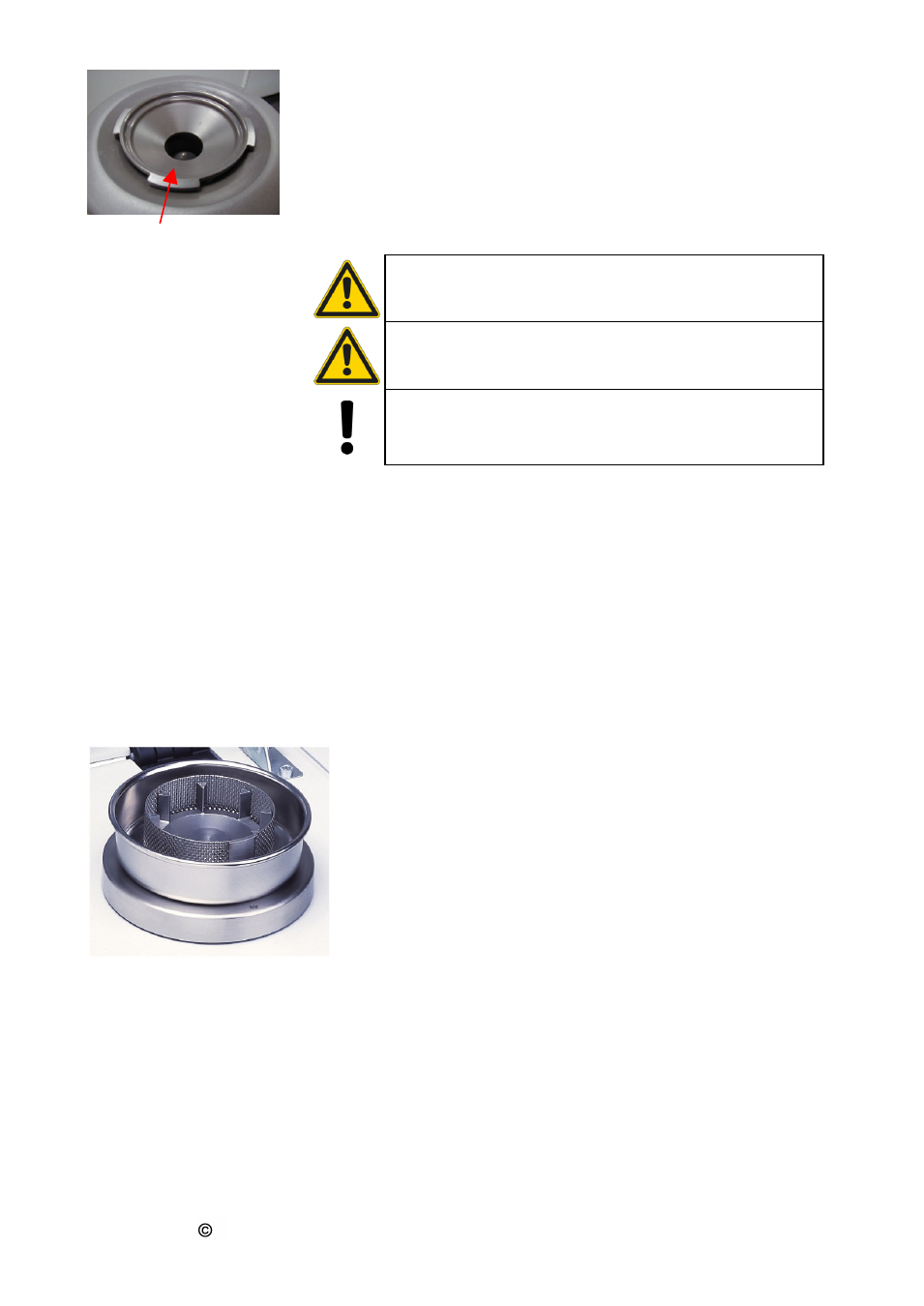

When cold grinding with liquid nitrogen, always install the anti-

rebound fitting X in the filling hopper.

Danger of injuries to eyes and skin from extreme freezing.

Wear safety gloves and goggles. Temperature of the liquid nitrogen

–196°C

Danger of injuries to eyes and skin from extreme freezing.

When cold grinding, do not forcibly remove the plug-on rotor,

which jams easily for physical reasons, but rather wait for the

temperature to level out.

Forced removal causes damage to the motor shaft and the

rotor.

Comminution with distance ring sieves

The

deployment

of

distance

ring

sieves

is

recommendable when materials with a low melting point

are to be ground, or wherever the rise in temperature

caused by comminution needs to be kept as low as

physically possible.

The ring sieve's low friction quotient due to the larger

distance to the rotor means that the grinding result will

be slightly coarser than if a standard ring sieve of the

same hole size is used.

Comminution of extremely small volumes

Grinding tools made of corrosion-resistant steel 1.4404

(316L) are available for grinding small sample volumes of

up to 50 ml.

The figure on the left shows the collecting vessel, ring sieve

and rotor for extremely small volumes.

The cassette cover, which is included in the scope of supply,

is not depicted here.