Assembly of accessories, Paper filter with retainer installation procedure – Retsch ZM 200 User Manual

Page 22

08.02.2012

Retsch GmbH

22

0003

Assembly of accessories

Larger volumes of material are often ground in a single

work process by continuously feeding in the material to

be comminuted.

The standard collecting vessel has a limited capacity, so

that it is necessary to use a larger collecting vessel.

Retsch offers the option of increasing the take-up

capacity and the feed quality by fitting accessories.

Paper filter with retainer and throughput vessel

Cyclone separator with collecting container and

throughput vessel V=3000ml or V=5000ml

Distributor of type DR100 with tripod

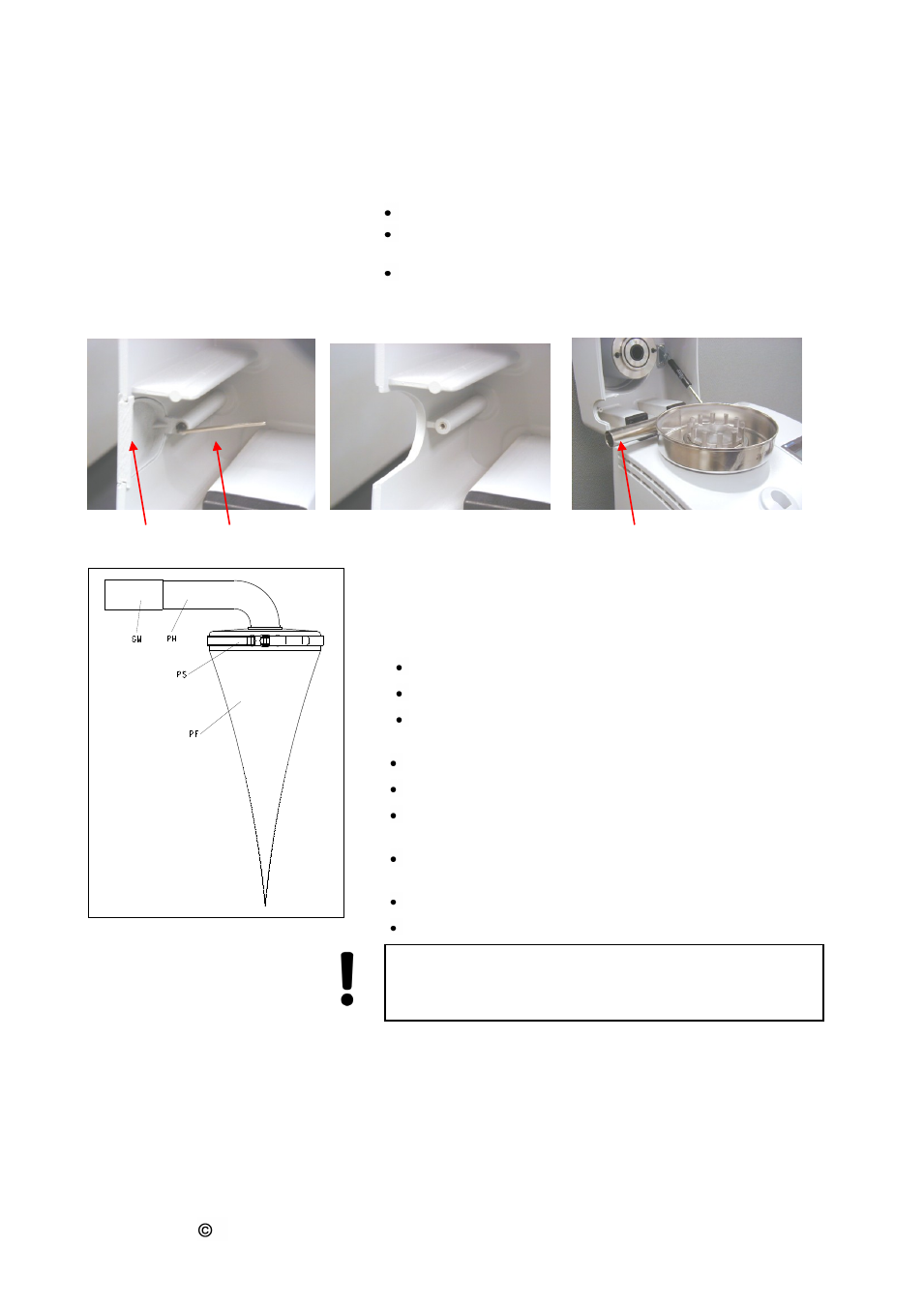

Paper filter with retainer

GA

IS

DG

Your ZM200 can be retrofitted with a throughput vessel with

an outlet instead of the standard, closed collecting vessel.

This throughput vessel is part of the scope of supply for the

paper filter with retainer.

Installation procedure

Remove the cylinder screw with Inbus key IS

Remove cover GA

Insert throughput vessel DG instead of the standard

collecting vessel with ring sieve and cassette cover

Pull rubber sleeve GM halfway over retainer PH

Fold back the other half of rubber sleeve GM

Push the pipe socket of retainer PH over the

pipe socket of throughput vessel DG

Fold rubber sleeve GM over the pipe socket of

throughput vessel DG

Slide paper filter PF onto retainer PH

Fasten the paper filter with clip PS.

The volume able to be taken up by the paper filter depends on the

density of the grinding material and the hole width of the ring

sieve.

The paper filter can be destroyed by overfilling and by the

weight of the comminution material