General – Retsch SK 100 User Manual

Page 18

05/04/2012

Retsch GmbH

18

0002

General

Cleaning

Fig.15

The SK 100 can be cleaned with normal brushes, paintbrushes

and possibly an industrial vacuum cleaner, as well as compressed

air.

To clean the grinding chamber of the SK 100 comfort the mo-

tor brake can be released at lever G (

Fig.15

). The cross beater

can now be easily turned and this facilitates cleaning.

The type of protection for the SK 100 is IP54.

!

Do not clean SK 100 with flowing water.

Danger of fatal electric shock

Servicing

The SK 100 is largely maintenance-free.

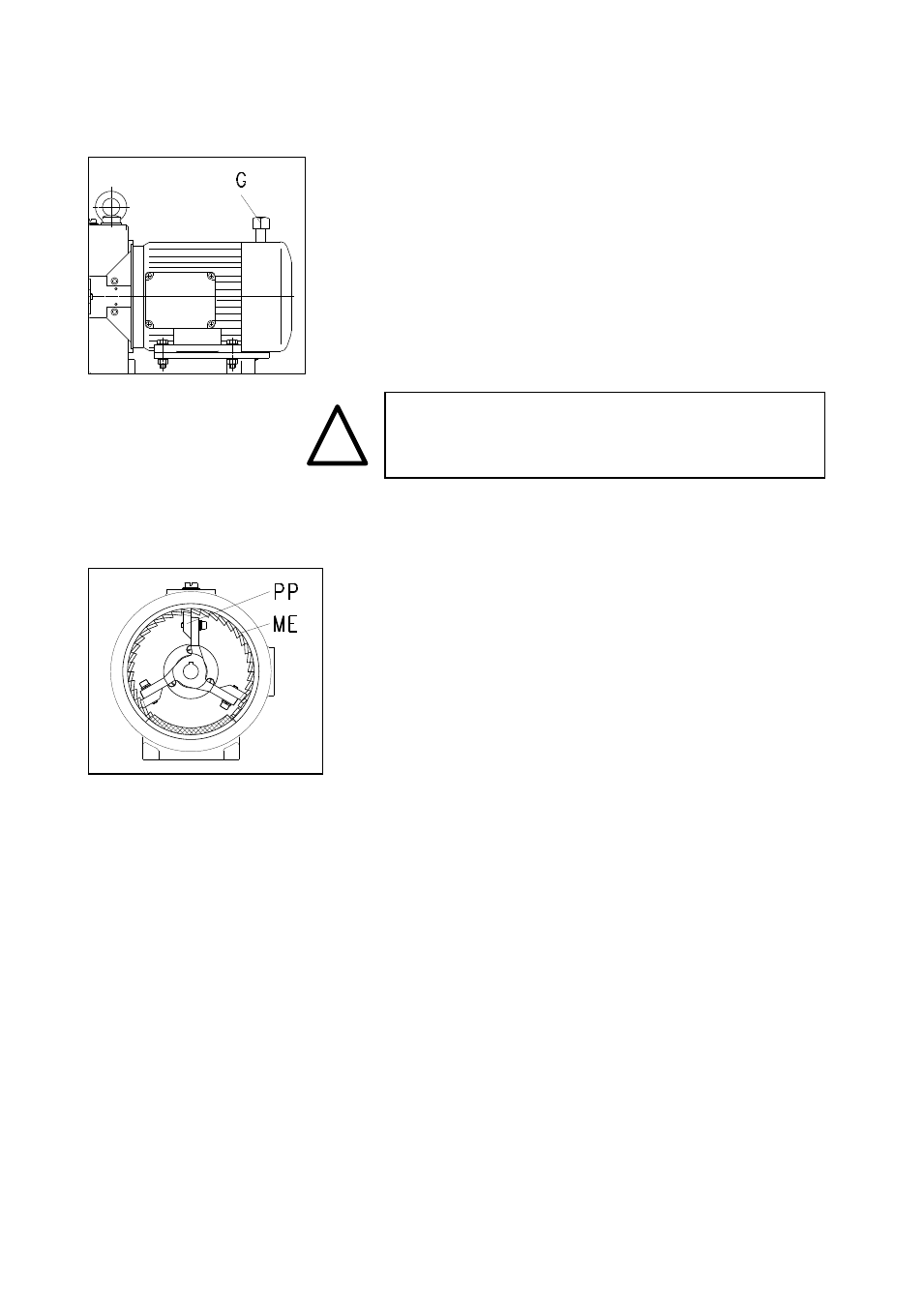

Fig.10

From time to time the gap between the grinding insert and the

impact plates of the cross beater should be checked.

Fig.10

* Pull out mains plug

* Open mill housing

* Check gap between grinding insert ME and impact plate

PP using a leaf gauge = required 1mm

The split to the bottom sieve never < 1mm puts in.

* If necessary reset impact plates using a socket spanner SW5

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- BB 300 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- DM 400 (60 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SM 100 (48 pages)

- SM 200 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 (36 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 25 (32 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)